Green tire register

A technology for storing raw tires and tires, applied in the field of rubber machinery, can solve problems such as easy deformation, and achieve the effects of easy operation, convenient adjustment and good linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

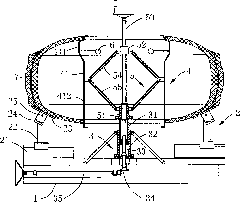

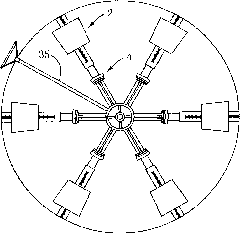

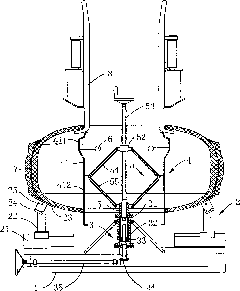

[0022] Such as figure 1 and figure 2 As shown, a raw tire storage device includes a base 1 , an outer tray 2 , a lifting device 3 and an inner jaw plate 4 . The outer tray 2 includes an outer pallet unit arranged in a circular array on the base 1, the center of the array of the outer tray 2 is coaxial with the center of rotation of the green tire 7, and the outer pallet unit includes The supporting arm 22 and the outer supporting plate 23 for supporting the shoulder of the raw tire 7, the supporting arm 22 is installed on the base 1; the lifting device 3 includes a fixing part, a lifting part and a driving part for driving The lifting part is a drive part for lifting relative to the fixed part, the fixed part is fixed on the base 1, the lifting part and the fixed part are axially fitted together, the lifting part of the lifting device 3 is connected to the outer The array center of the tray 2 is coaxially installed; the inner jaw plate 4 includes a group of tire claws 41 hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com