Cage-shaped structure composite hydrogen storage method

A hydrogen storage and cage technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of low gas storage density, high required temperature, single hydrogen storage method, etc., and achieve simple hydrogen release process and storage. The effect of mild hydrogen conditions and high hydrogen storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

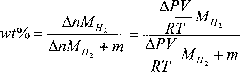

[0038]0.5g 1-butenal is dissolved in acetone, the formation mass fraction is the acetone solution of 70% 1-butenal, will be loaded with catalyst TiO 2 The molecular sieves were impregnated in the acetone solution of 1-butenal for 4 days, then taken out and put into the autoclave. Seal the high-pressure reaction kettle, pump out the air in the kettle to make the vacuum degree 0.5MPa, pass the cooling liquid (-5°C, silicone oil) in a constant temperature cold bath, wait for the temperature in the kettle to drop to -5°C, and after it stabilizes, open the hydrogen inlet valve , adjust the pressure in the kettle, adjust the pressure to 2MPa (P 1 ), stop the hydrogen flow, turn on the light source, so that the inside of the high-pressure reactor is in an environment with light and catalyst. After the pressure is stabilized, the pressure is 0.6MPa(P 2 ), the organic hydrogen cage compound is completely generated, the light source is turned off, and the hydrogen storage ends. The h...

Embodiment 2

[0040] 6g 2-hexenoic acid is dissolved in acetone to form an acetone solution whose mass fraction is 90% 2-hexenoic acid, and the catalyst TiO 2 The molecular sieves were impregnated in the acetone solution of 2-hexenoic acid for 3 days, then taken out and put into the autoclave. Seal the high-pressure reaction kettle, pump out the air in the kettle to make the vacuum degree 0.6MPa, and pass the cooling liquid (10°C, silicone oil) in a constant temperature cooling bath. The pressure in the kettle is adjusted to 20MPa (P 1 ), stop the hydrogen flow, turn on the light source, so that the inside of the high-pressure reactor is in an environment with light and catalyst. After the pressure is stabilized, 3MPa(P 2 ), the organic hydrogen cage compound is completely generated, the light source is turned off, and the hydrogen storage ends. Calculate the hydrogen storage capacity according to the formula (1), and the total hydrogen storage capacity is 7.2wt%. Compared with simple o...

Embodiment 3

[0042] 6g 2-pentenol is dissolved in acetone to form an acetone solution with a mass fraction of 90% 2-pentenol, and the loaded catalyst Pt / InVO 4 / TiO 2 The molecular sieves were impregnated in the acetone solution of 2-pentenol for 3 days, then taken out and put into the autoclave. Seal the high-pressure reaction kettle, pump out the air in the kettle to make the vacuum degree 0.8MPa, and pass the cooling liquid (20°C, silicone oil) in a constant temperature cooling bath. The pressure in the kettle is adjusted to 29MPa (P 1 ), stop the hydrogen flow, turn on the light source, so that the inside of the high-pressure reactor is in an environment with light and catalyst. After the pressure is stabilized, 29MPa(P 2 ), the organic hydrogen cage compound is completely generated, the light source is turned off, and the hydrogen storage ends. The hydrogen storage capacity is calculated according to the formula (1), and the total hydrogen storage capacity is 8.6wt%. Compared wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com