Fuel battery system and method for controlling quantity of reaction gas supplied

A fuel cell system and reaction gas technology, applied in the direction of fuel cells, fuel cell additives, electrical components, etc., can solve problems such as the inability to control the supply with high efficiency, and achieve the effect of reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

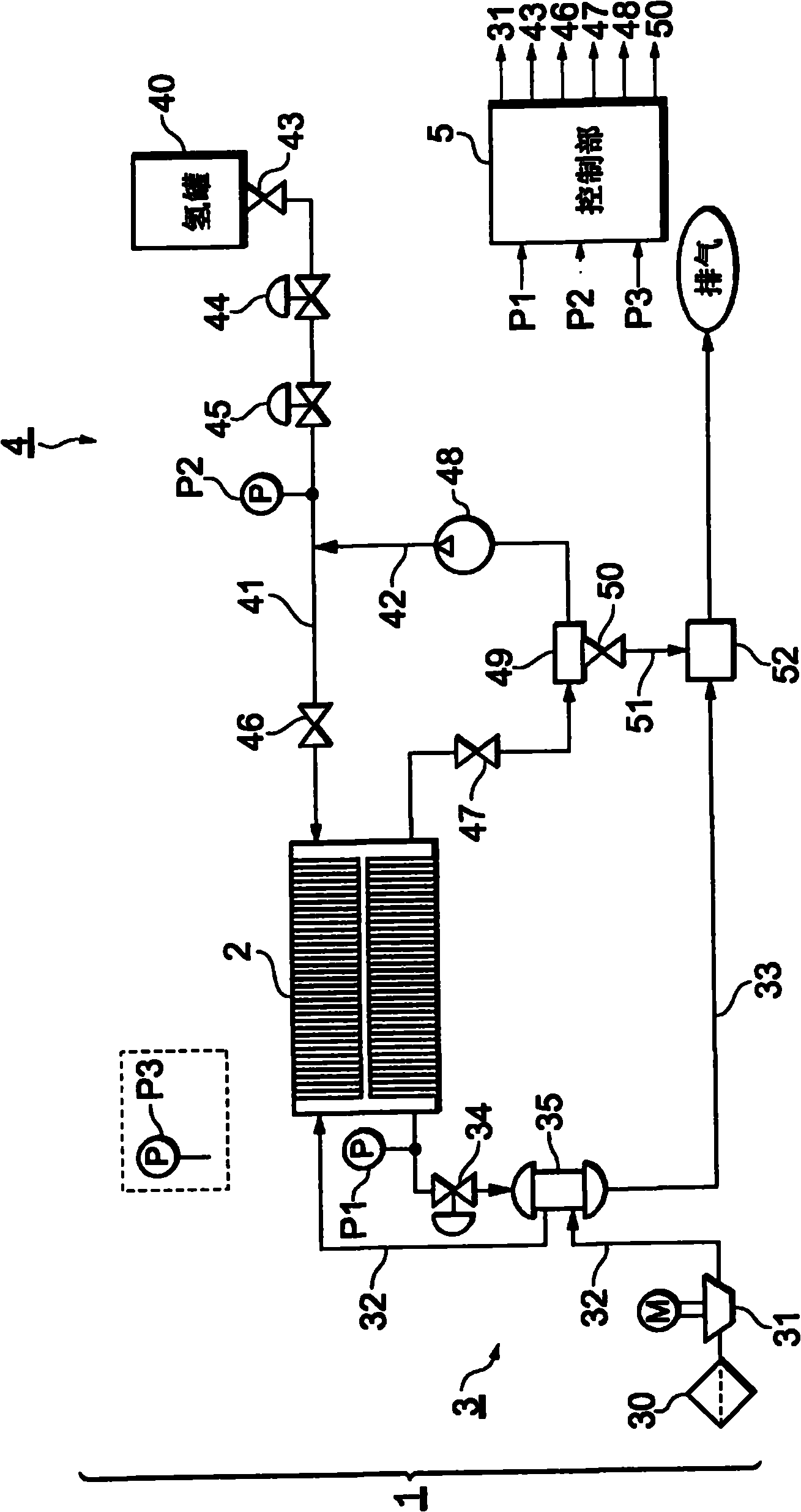

[0027] Next, preferred embodiments of the fuel cell system and the reaction gas supply amount control method according to the present invention will be described with reference to the drawings. In this embodiment, a case where the fuel cell system according to the present invention is used as an on-vehicle power generation system of a fuel cell vehicle (FCHV; Fuel Cell Hybrid Vehicle) will be described.

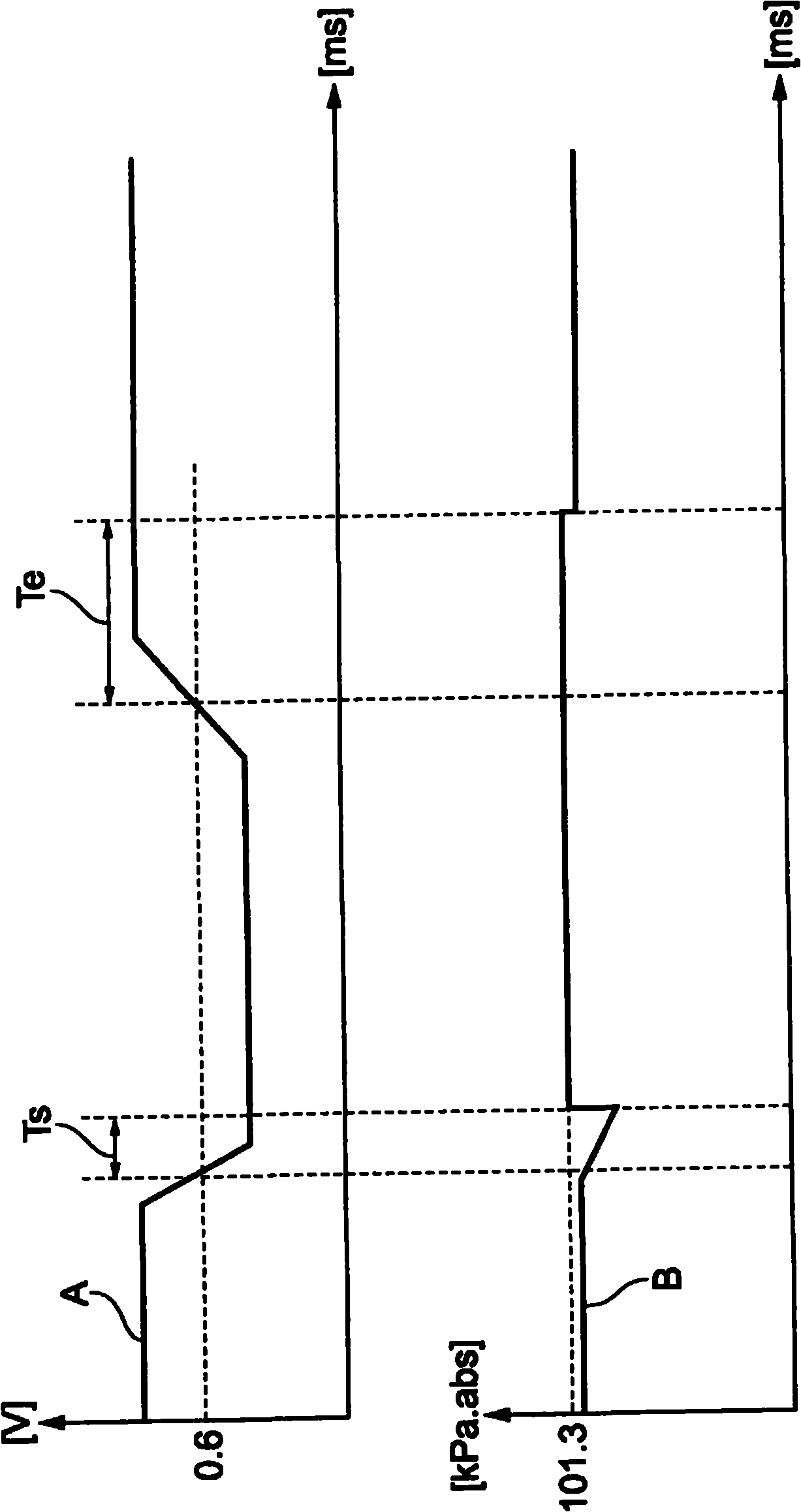

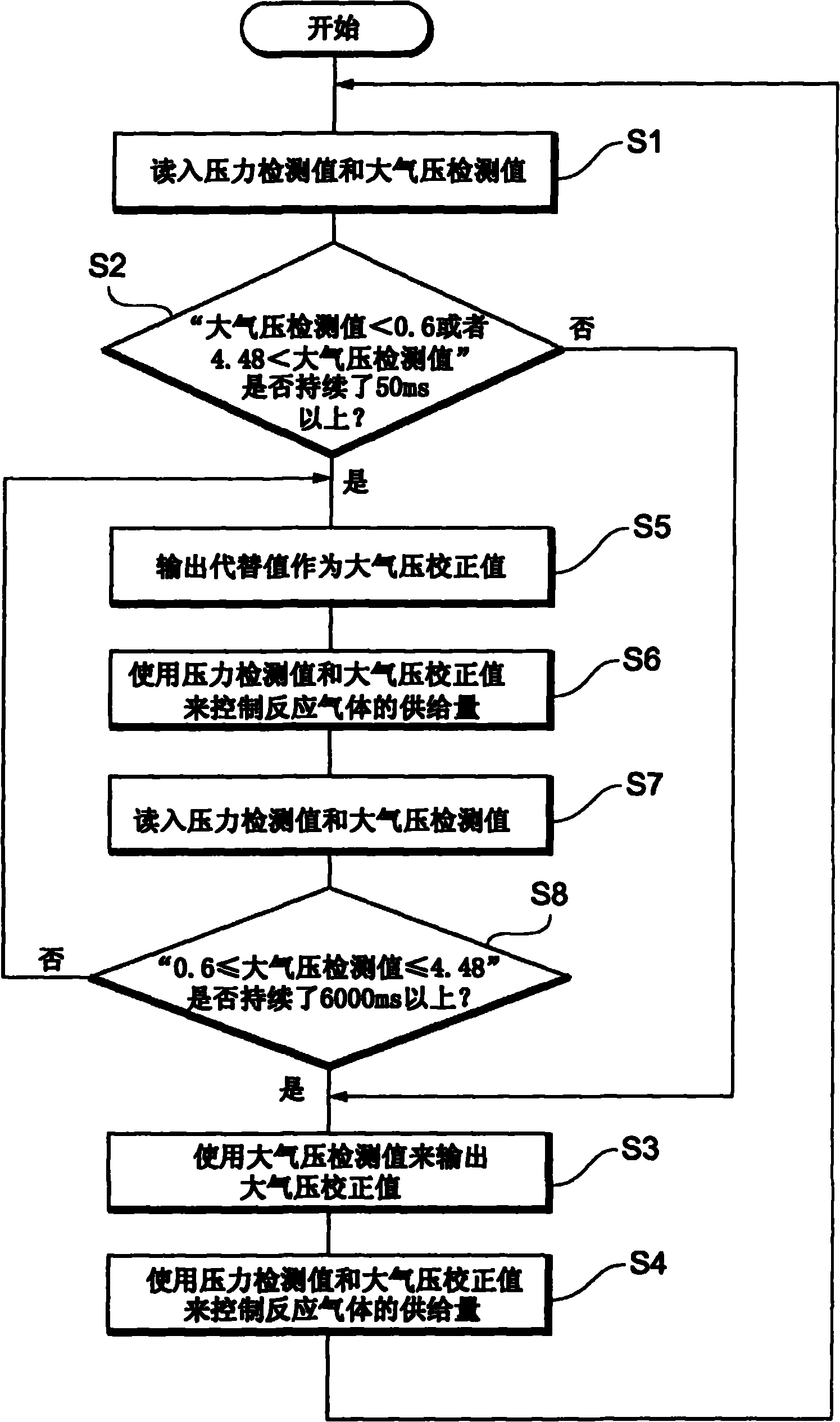

[0028] The fuel cell system in this embodiment detects the pressure of the reactant gas in the supply and discharge flow path for supplying or discharging the reactant gas with a gauge pressure sensor, and corrects the pressure of the reactant gas by using the detection value of the gauge pressure sensor and the detection value of the atmospheric pressure sensor. The absolute pressure is calculated from the obtained value, and the supply amount of the reactant gas to the fuel cell is controlled based on the absolute pressure.

[0029] First, refer to figure 1 , the configura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com