Induction heating method

A technology of induction heating and induction voltage, applied in induction heating, induction heating device, electric/magnetic/electromagnetic heating, etc., can solve problems such as loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

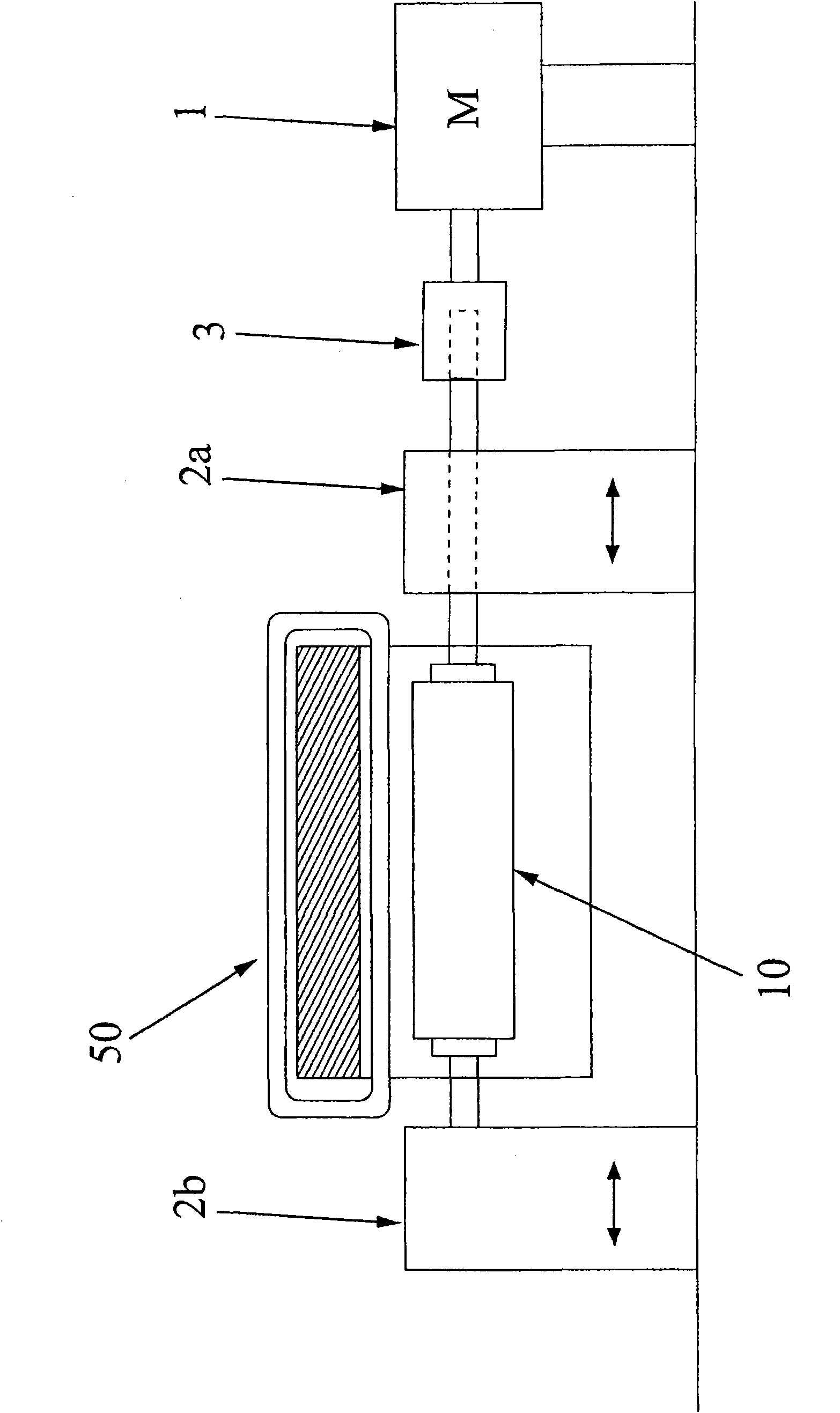

[0035] figure 1 The induction heater of ® is used to heat the blank 10 by rotating the blank 10 in the magnetic field generated by the magnet system 50 . To this end, a blank 10 is clamped between the right-hand and left-hand pressure elements 2a and 2b of the clamping device and driven in rotation by the electric motor 1 . A gear transmission 3 connects the motor shaft to the shaft of the gripper 2a adapted to slide in the direction of the double arrow.

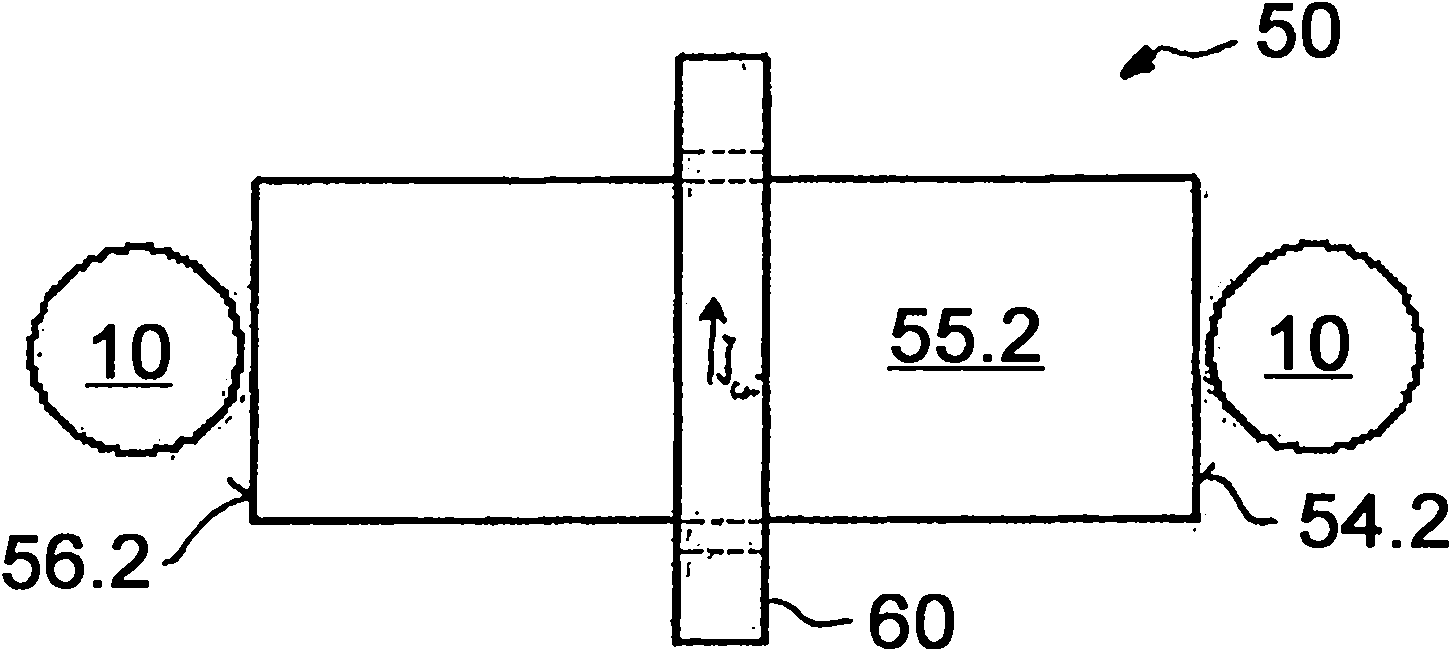

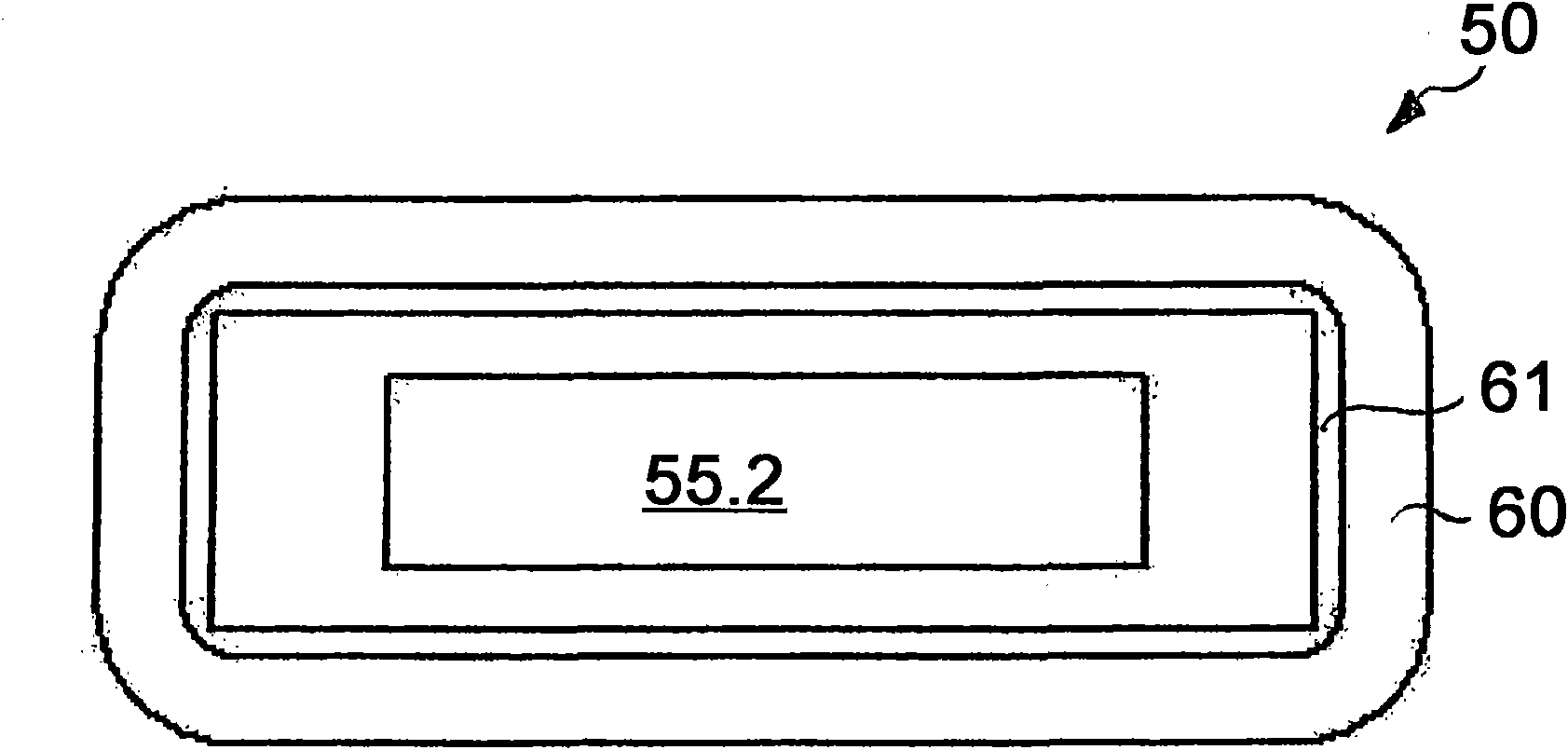

[0036] as in Figure 2a and 2b Shown in a very simplified manner in , the magnet system 50 may comprise a DC-fed superconducting winding 60 on a bar core 55.2. Between the winding 60 and the iron core 55.2, an isolation element 61 is provided, such as an evacuated hollow space, which can reduce the heat entering the winding 60 (only in the Figure 2b shown in ). The rod-shaped iron core 55.2 conducts the magnetic field (not shown) generated by the DC-fed winding 60, which emanates from the two end faces 56.2 and 57.2 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com