Granular edible fungus strains and production method thereof

A production method and technology for edible fungi, which are applied in the directions of botanical equipment and methods, applications, fertilizer mixtures, etc., can solve the problems of poor uniformity of strain usage, short storage time, unbalanced mycelial growth, etc., and achieve the inoculation process. The effect of complex simplification, prolonged storage time, and stable growth balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

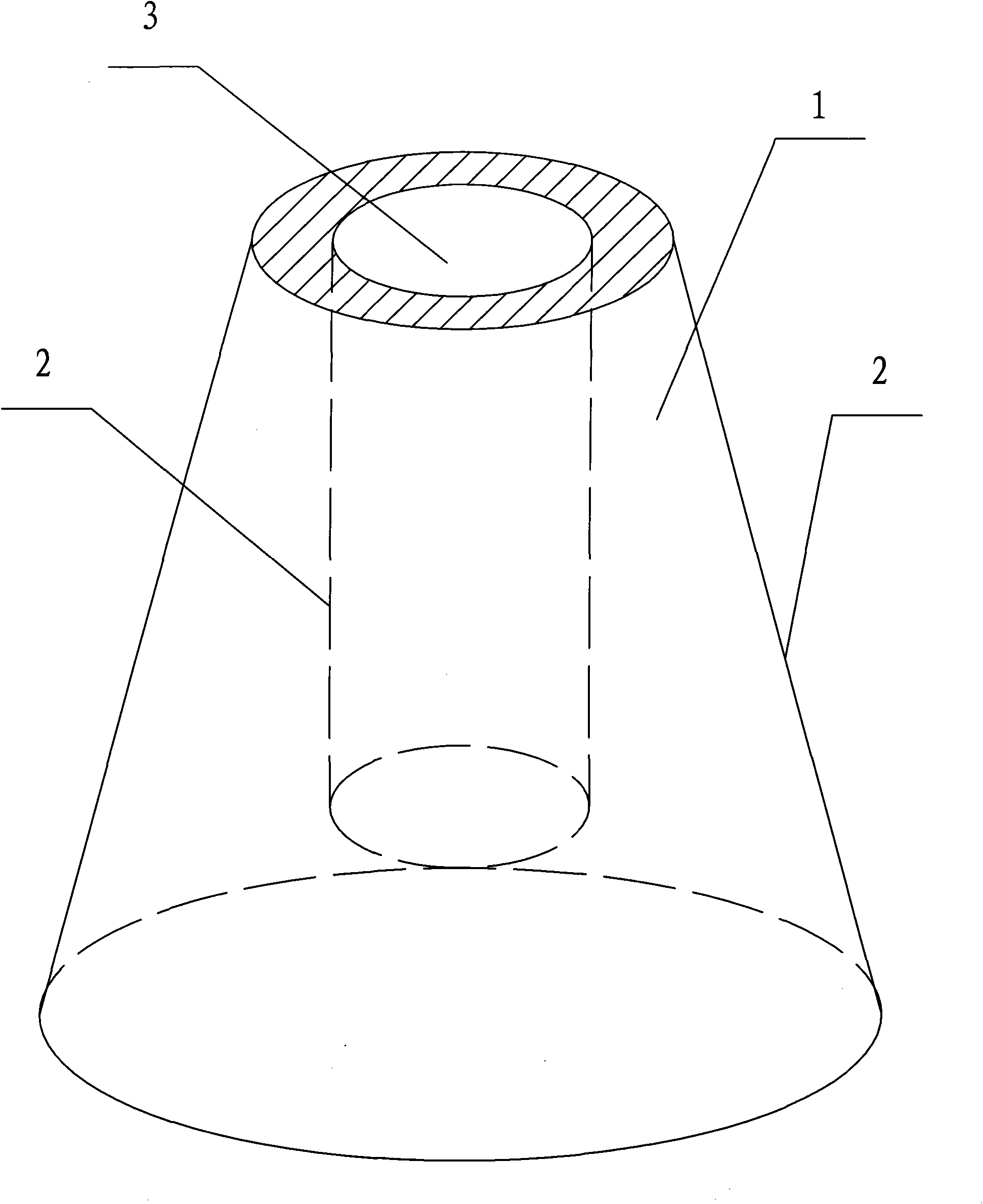

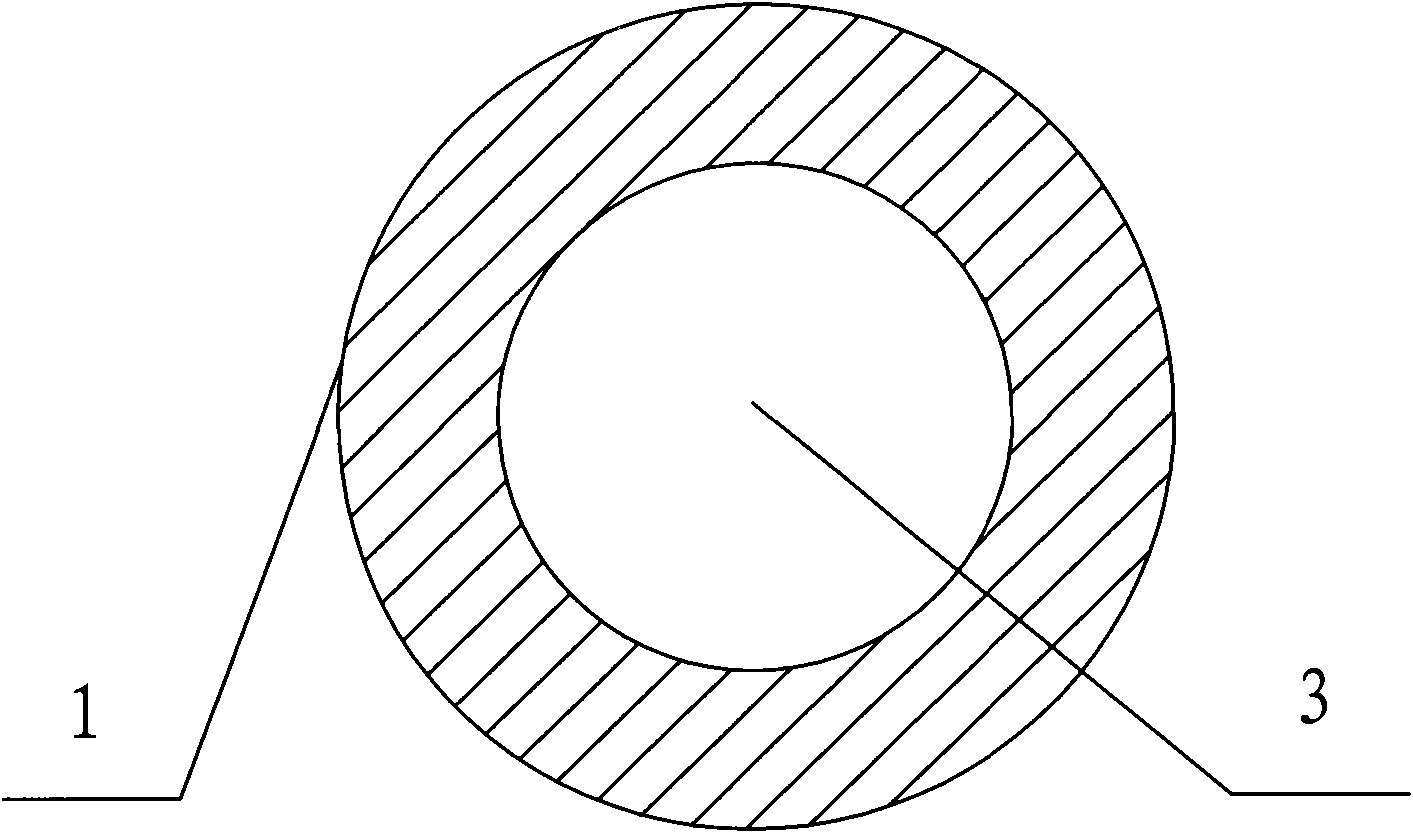

[0020] figure 1 , 2 , the granular edible fungus bacterial classification of the present invention shown in 3 and 4, comprises conical wood grain 1 and edible fungus mycelium 2, and conical wood grain 1 is provided with a hole 3, and the opening of hole 3 is positioned at conical shape The upper bottom surface of the wood particle 1. The diameter of the upper bottom surface of the conical wood particle 1 is 0.5 cm to 2 cm, the lower diameter of the conical wood particle 1 is 0.6 cm to 2.4 cm, and the distance between the upper and lower bottom surfaces of the conical wood particle is 0.6 cm to 3.0 cm. The openings of the holes 3 are all located on the upper bottom surface of the conical wood particle 1, and the diameter of the holes 3 is 0.1cm-1.8cm.

[0021] The above-mentioned conical wood grain 1 wooden bead manufacturing machine is produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com