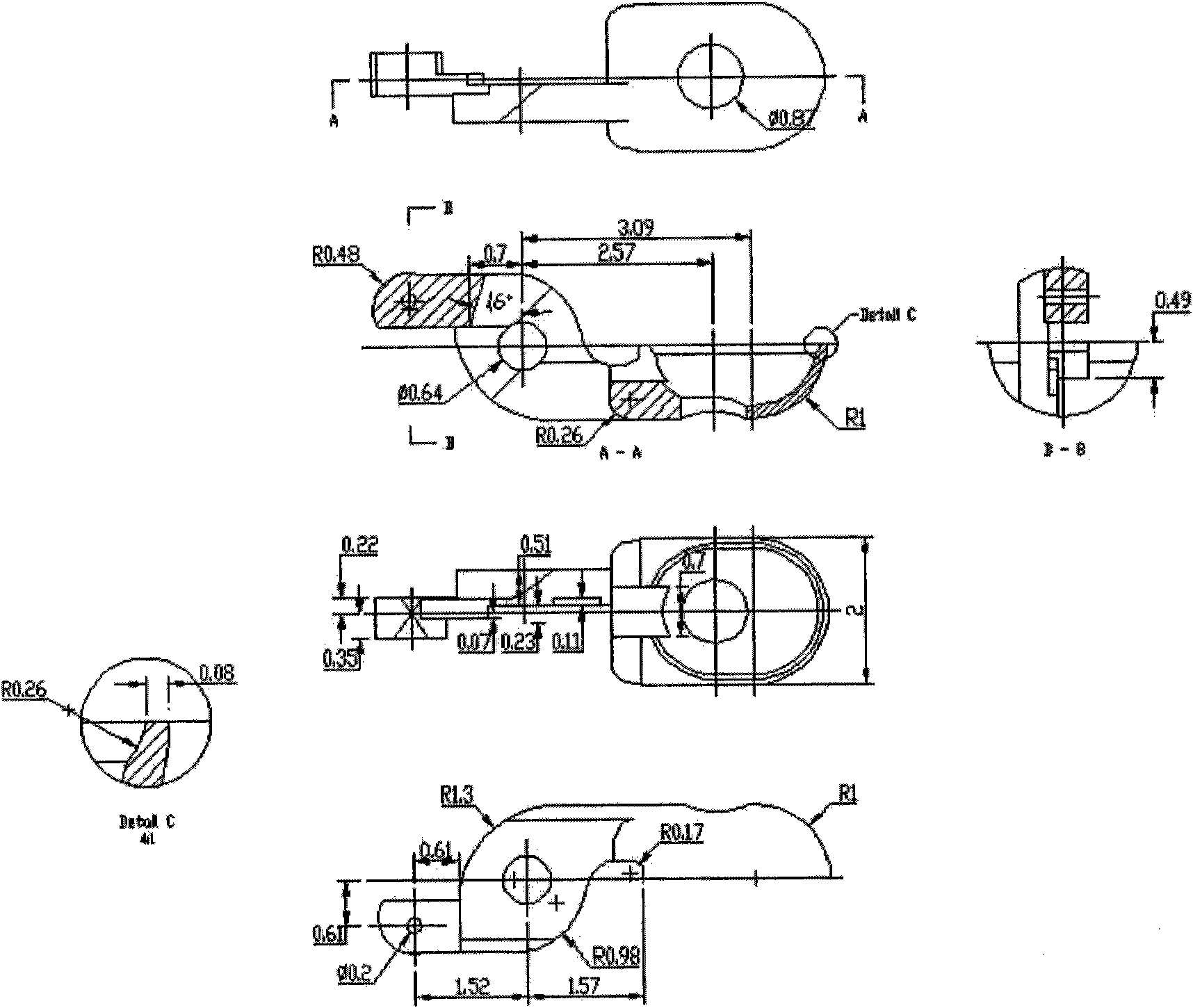

Method for preparing head of endoscope biopsy forceps used for minimally invasive surgery

A technology of minimally invasive surgery and endoscopy, applied in the direction of trocars, etc., can solve the problems of numerous procedures, high production cost, low yield rate, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

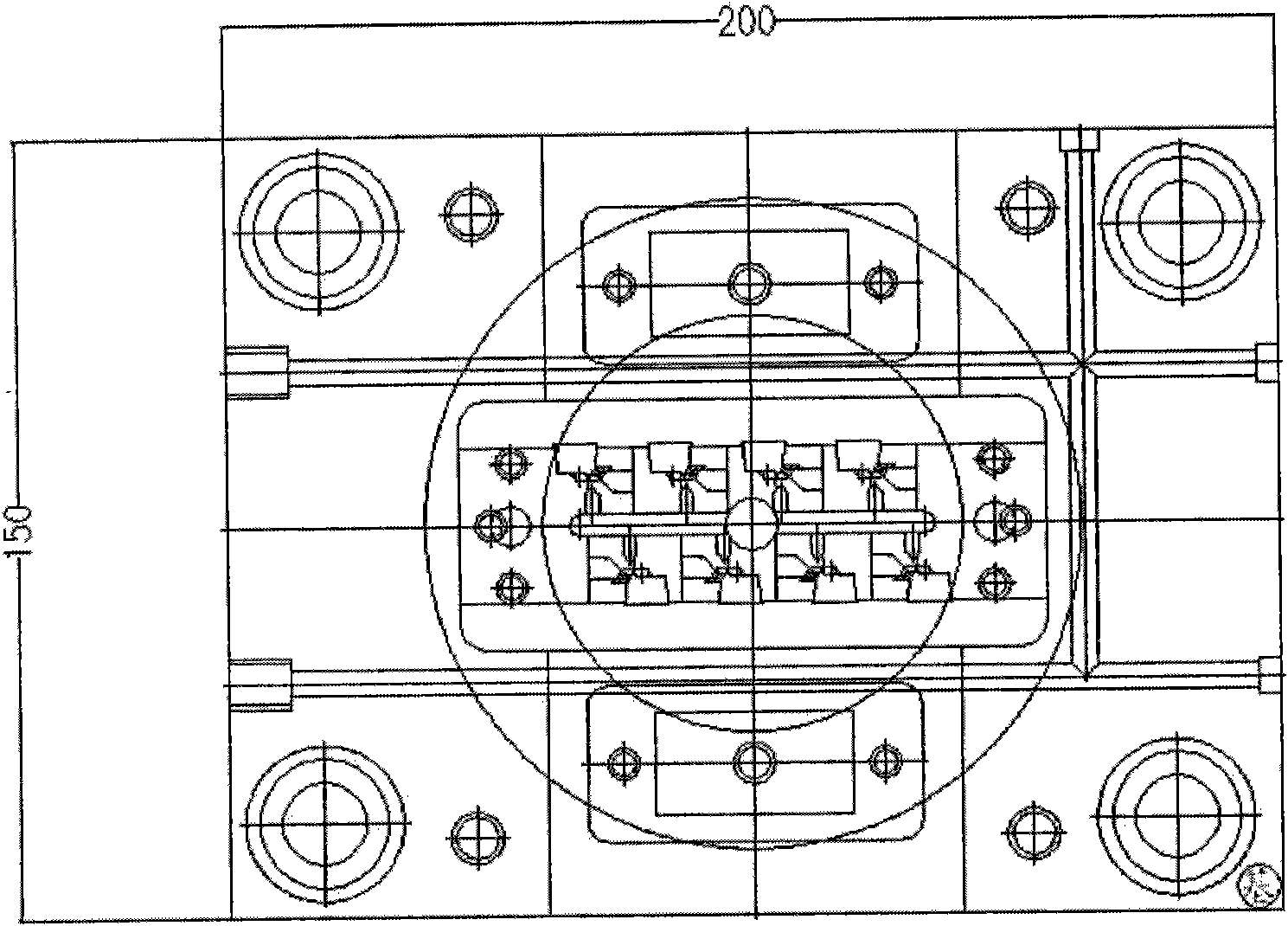

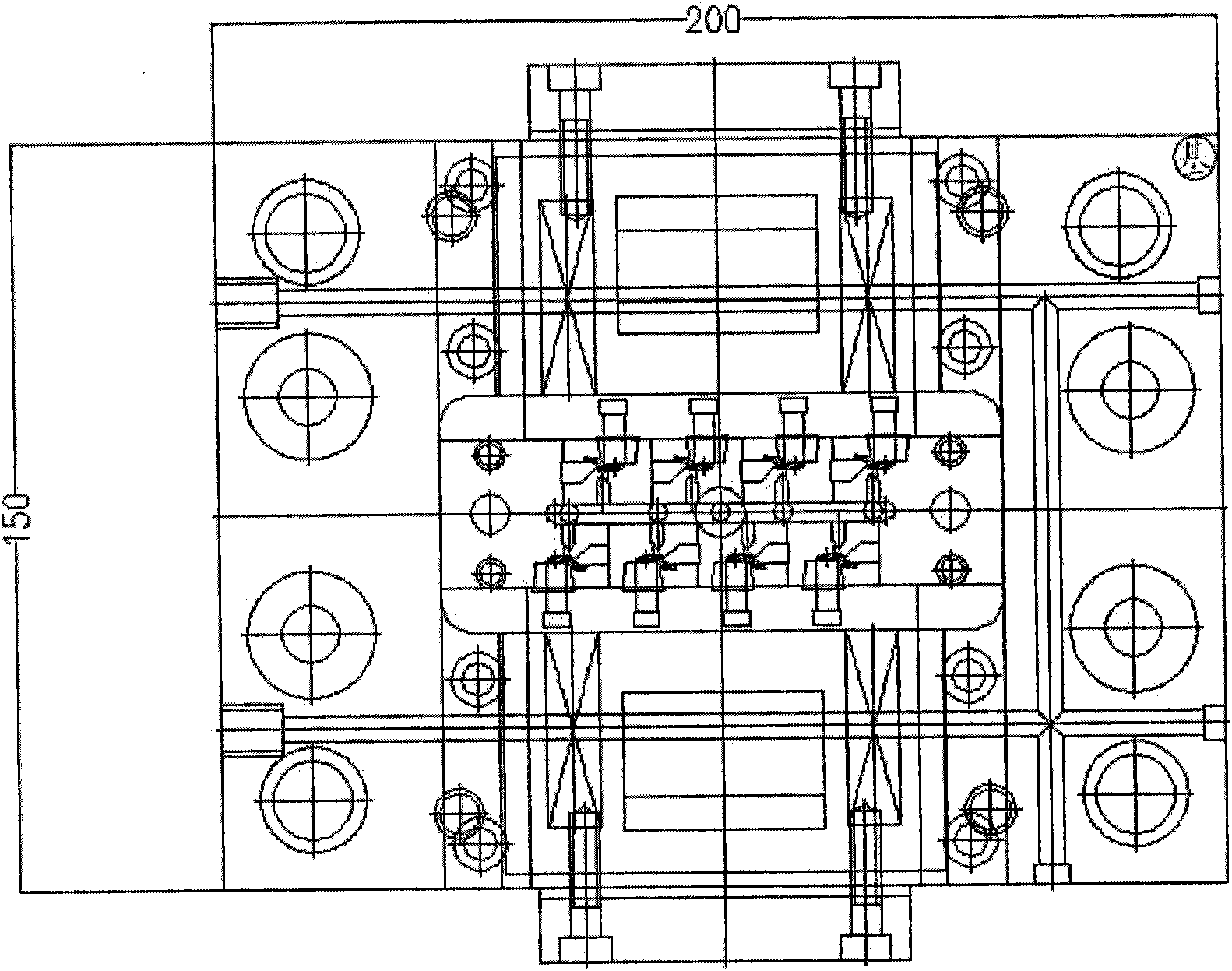

Method used

Image

Examples

preparation example Construction

[0008] A. preparation of binder: by weight percentage, get polyethylene glycol 10-15%, vegetable oil 15-30%, polyethylene 10-15%, polypropylene 5-20%, paraffin 25-45%, put blade In a type mixer, mix for 1 hour at a temperature of 140°C-160°C;

[0009] B. Ingredients: Weigh the stainless steel powder and binder according to the mass ratio of 80-95:20-5%, mix them in a planetary mixer at a temperature of 150-220°C for 1.5 hours, and make them after cooling and crushing into feeding.

[0010] C. Injection molding: put the prepared feed into BOY50T injection molding machine, injection temperature is 120-165°C, injection pressure is 60-120Mpa, mold temperature is 30-60°C, and the blank is formed by injection.

[0011] D. Degreasing: first place the blank in a dichloromethane solvent to dissolve the paraffin and vegetable oil components; then put the dried blank into a vacuum degreasing furnace, under the protection of hydrogen or argon, at 4 ° C / min heating to 180°C, holding for...

example 1

[0014] Example 1: Stainless steel powder and binder are mixed according to the mass ratio of 85:15, mixed at 180°C for 1.5 hours, injection temperature at 145°C, injection pressure at 80Mpa, mold temperature at 55°C, and sintered at 1375°C for 90 minutes after degreasing.

example 2

[0015] Example 2: Stainless steel powder and binder are proportioned in a mass ratio of 90:10, mixed at 180°C for 1.5 hours, injection temperature at 145°C, injection pressure at 90Mpa, mold temperature at 55°C, and sintered at 1375°C for 90 minutes after degreasing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com