Chopstick polisher

A technology of polishing machine and chopsticks, which is applied to surface polishing machine tools, grinding/polishing equipment, table utensils, etc., can solve the problems of inability to automatically complete grinding and polishing at the same time, difficult to improve production efficiency, and limited scope of use. Achieve the effect of high degree of automation, saving production cost and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

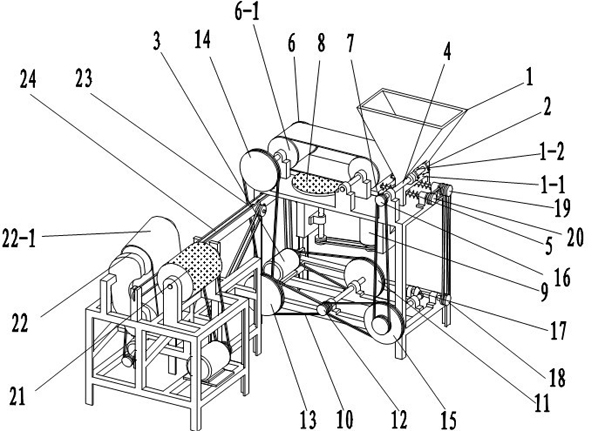

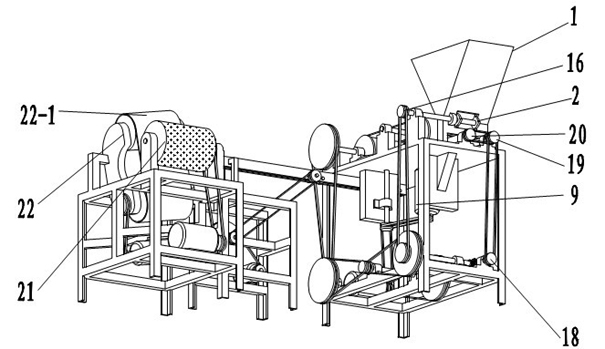

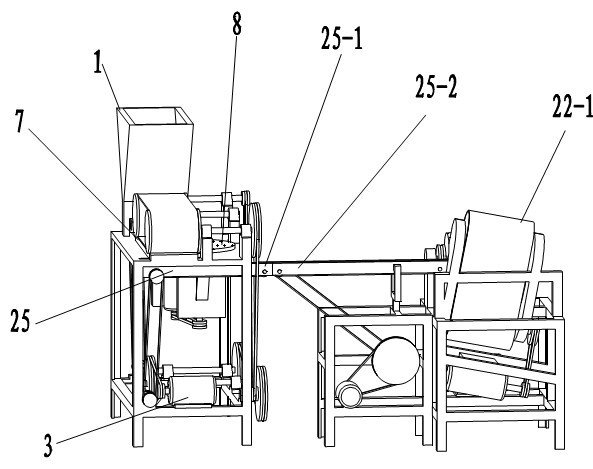

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] With reference to the accompanying drawings, this chopsticks grinder includes a molding device and a polishing device, and the molding device and the polishing device are connected by a conveyor pulley mechanism 25. The molding device includes:

[0024] The feeding mechanism includes a feeding hopper 1, the feeding hopper 1 is large at the top and small at the bottom, the upper part is open, and the lower part is a feeding chute 1-1 whose width is only for a chopstick semi-finished product to fall, the feeding chute 1-1 Side opening 1-2, opening 1-2 is provided with chopsticks chopsticks wheel 2 that can chopsticks semi-finished products in the groove to be grilled down, and chopsticks chopsticks wheel 2 is provided with four grilling teeth. The chopsticks wheel 2 is fixed on the rotating shaft 4 driven by the main motor 3; the feeding screw 5 driven by the main moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com