Five degree-of-freedom reconfigurable modular service robot arm

A service robot and degree of freedom technology, applied in the field of robot arms, can solve the problems of complex arm structure, high quality and high cost, and achieve the effect of compact overall structure, large working space and good packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

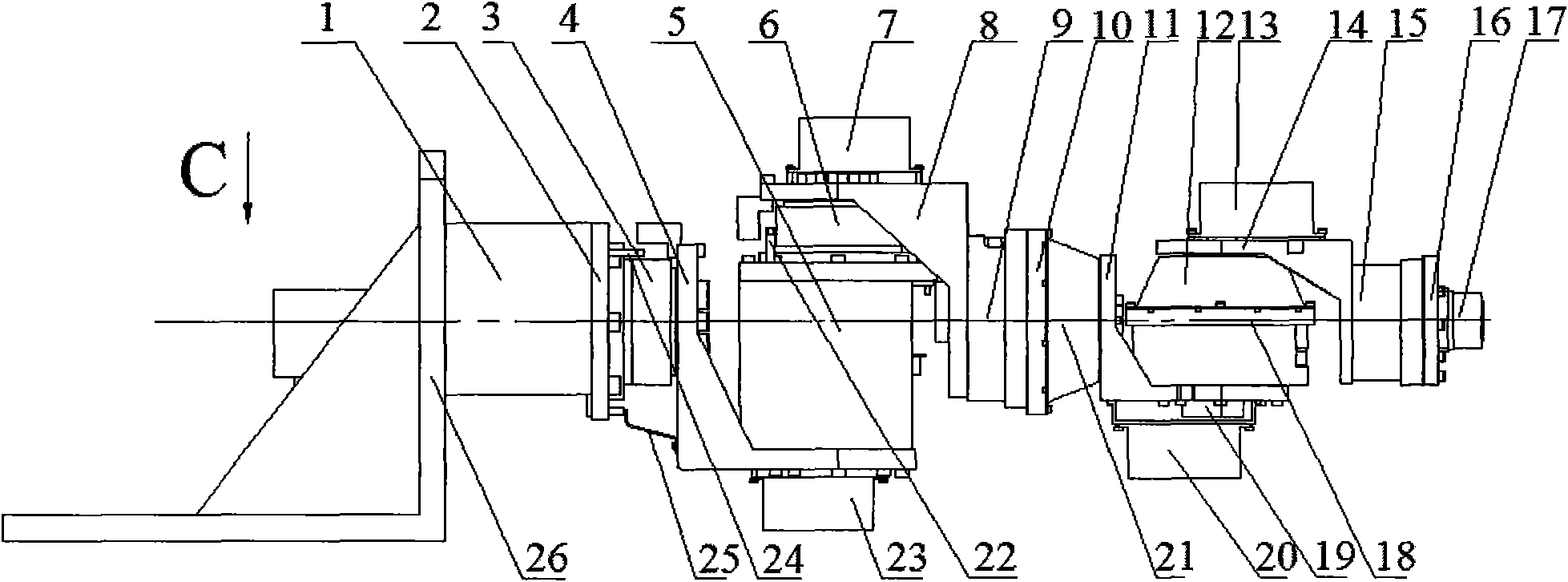

[0026] Embodiment one: see figure 1 , the five-degree-of-freedom reconfigurable modular service robot arm includes a large arm, a small arm and a control system. The large arm is composed of a base connected to a first joint and a second joint in turn, and the first joint is used for rotation. Movement, with one degree of freedom, the second joint performs swinging motion, with one degree of freedom; the forearm is composed of a third joint, a fourth joint, and a fifth joint connected in sequence, and the three joints all rotate The movement each has one degree of freedom; the five joints are all modular joints, which are sequentially connected through four connecting frames to form an open-chain space mechanism with five degrees of freedom.

Embodiment 2

[0027] Embodiment two: see figure 1 , this embodiment is basically the same as Embodiment 1, and the special feature is: the structure that the five joints are sequentially connected through four connecting frames is: the threaded hole 62 on the base 26 is fixed on the mobile platform by screws, the first The boss in the joint has a sleeve-1 and the hole on the base 26 constitutes a base hole system transition fit and is fixed together by screws. The first joint and the second joint are connected together by a connecting frame-4, wherein the first In the joint, the output end of the harmonic reducer 1 and the outside of a vertical panel in the connecting frame 4 are fixed together by screws, and the second joint has the boss in the sleeve 2 5 and the other piece of the connecting frame 4 The holes in the inner panel of the vertical panel form the transition fit of the base hole system and are fixed together by screws. In turn, the second joint has the output end of the harmoni...

Embodiment 3

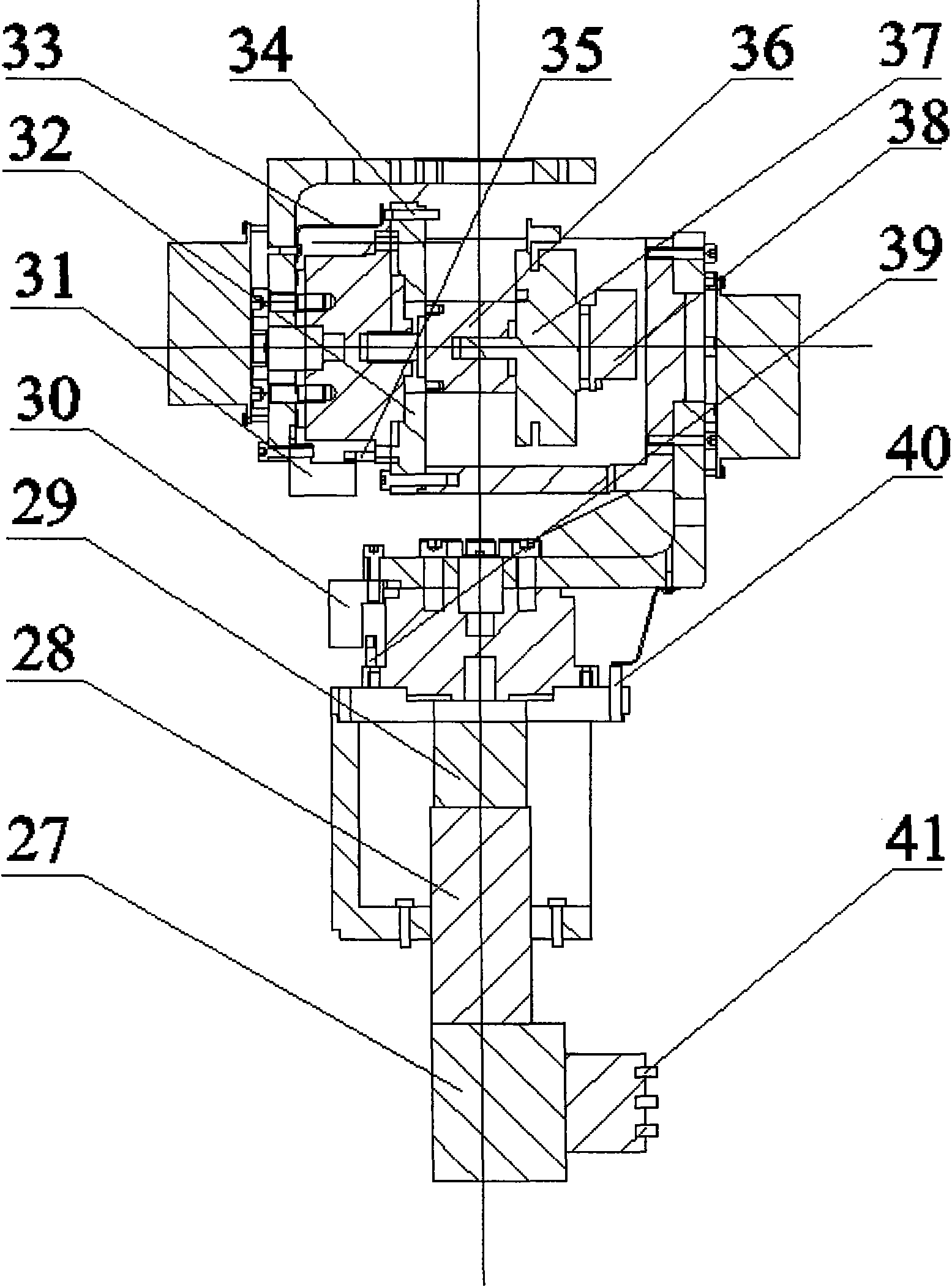

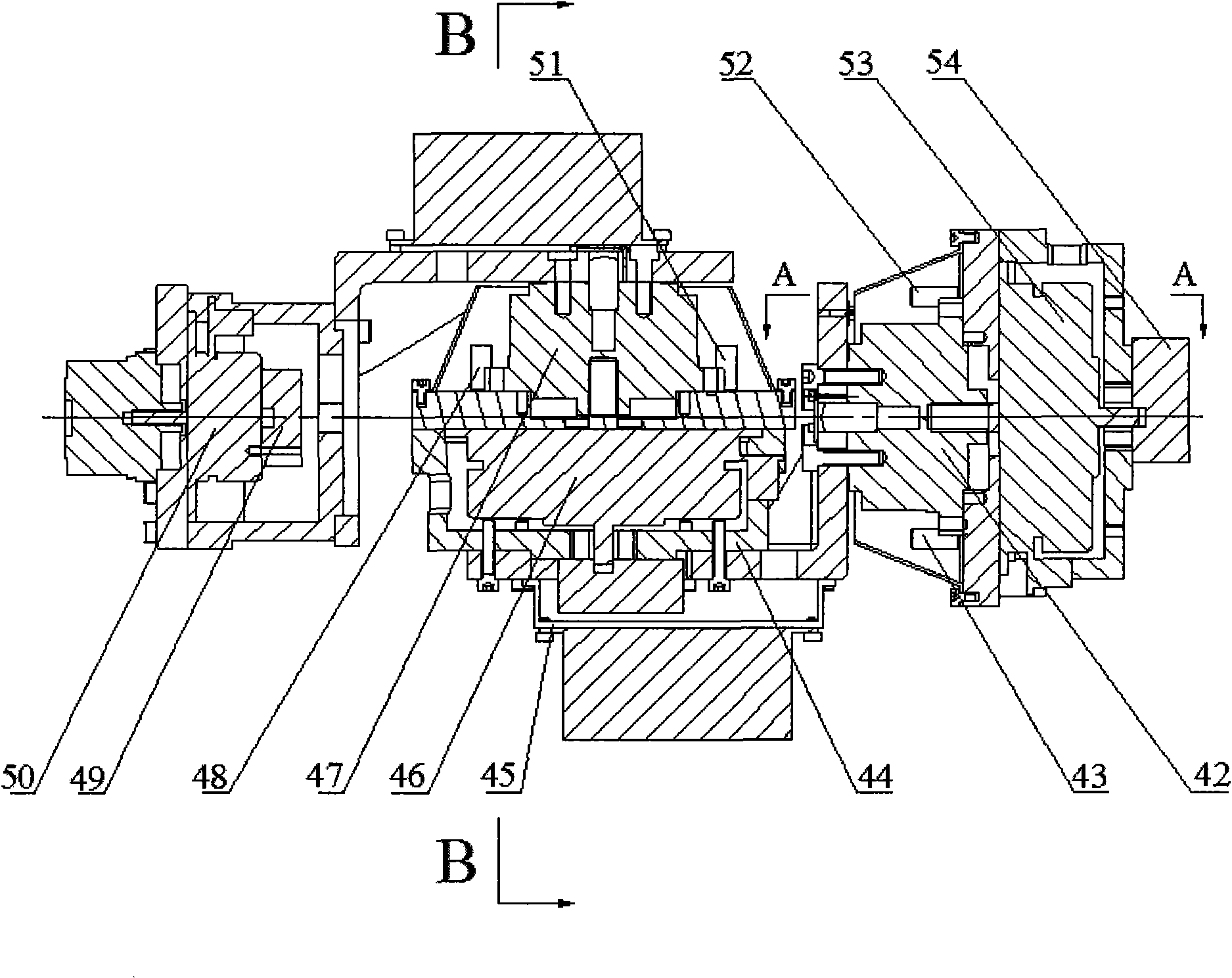

[0028] Embodiment three: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present embodiment is basically the same as Embodiment 2, and the special features are as follows: the first modular joint includes: DC servo motor-28, brake 27, planetary gearbox-29, driver-61, sensor-40, harmonic deceleration Device one 3, connecting plate one 2, sleeve one 1, there is wiring hole 41 on the brake 27, and its connection relationship is: brake 27, DC servo motor one 28 and planetary gear box one 29 are packaged in the sleeve one 1 , the sleeve-1 is connected to the connecting plate-2 by screws, the input end of the harmonic reducer-3 is connected to the connecting plate-2 by screws, the output end of the harmonic reducer-3 is connected to the connecting frame-2 by screws, The driver one 61 is fixed on the base 26 with screws, the sensor one 40 is fixed on the connection plate one 20, the zero position non-contact sheet one 25 and the first joint stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com