Blast furnace cooling structure

A cooling structure and blast furnace technology, applied in the direction of cooling devices, etc., can solve the problems of cracked water leakage of cooling pipes, long leak detection time, precise positioning of water leakage places, etc., so as to avoid errors in manual judgment, shorten leak detection time, and ensure continuous sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

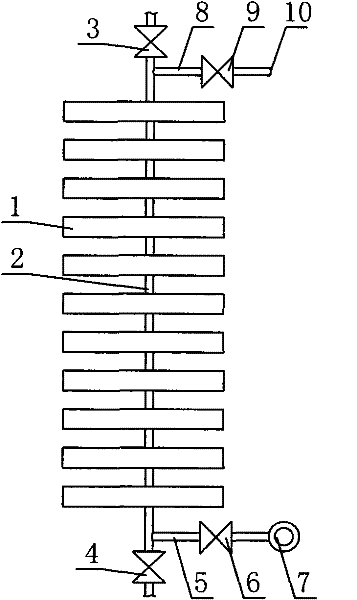

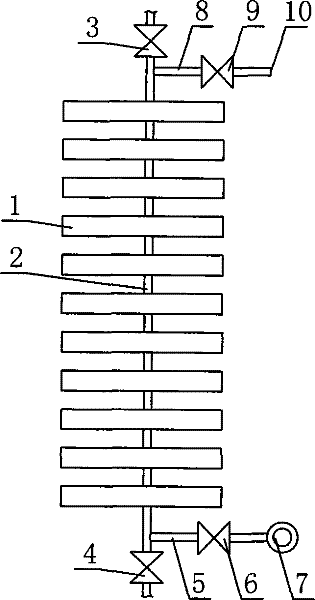

[0012] In specific implementation, such as figure 1 As shown, a blast furnace cooling structure includes several rectangular block-shaped staves 1, the staves 1 are made of cast iron, cooling water pipes 2 are arranged in the staves 1, the staves 1 are arranged in vertical rows and each vertical row The staves are penetrated by cooling water pipes 2 arranged vertically, wherein each vertical row of staves is divided into several groups, consisting of 11 staves 1, and the cooling water pipes 2 at the upper and lower ends of each group of staves 1 are provided with The upper on-off valve 3 and the lower on-off valve 4; on the cooling water pipeline 2 between the lower end of each group of staves 1 and the lower on-off valve 4, a lower bypass pipe 5 is horizontally connected, and a lower bypass pipe 5 is arranged in the lower bypass pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com