Automatic cloth clamps of embroidery machine

An embroidery machine and automatic technology, which is applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc. It can solve the problems of jumping out of the embroidery frame from time to time, high work intensity of workers, and poor working environment, so as to improve the per capita The effect of increasing the number of operating embroidery machines, improving competitiveness, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

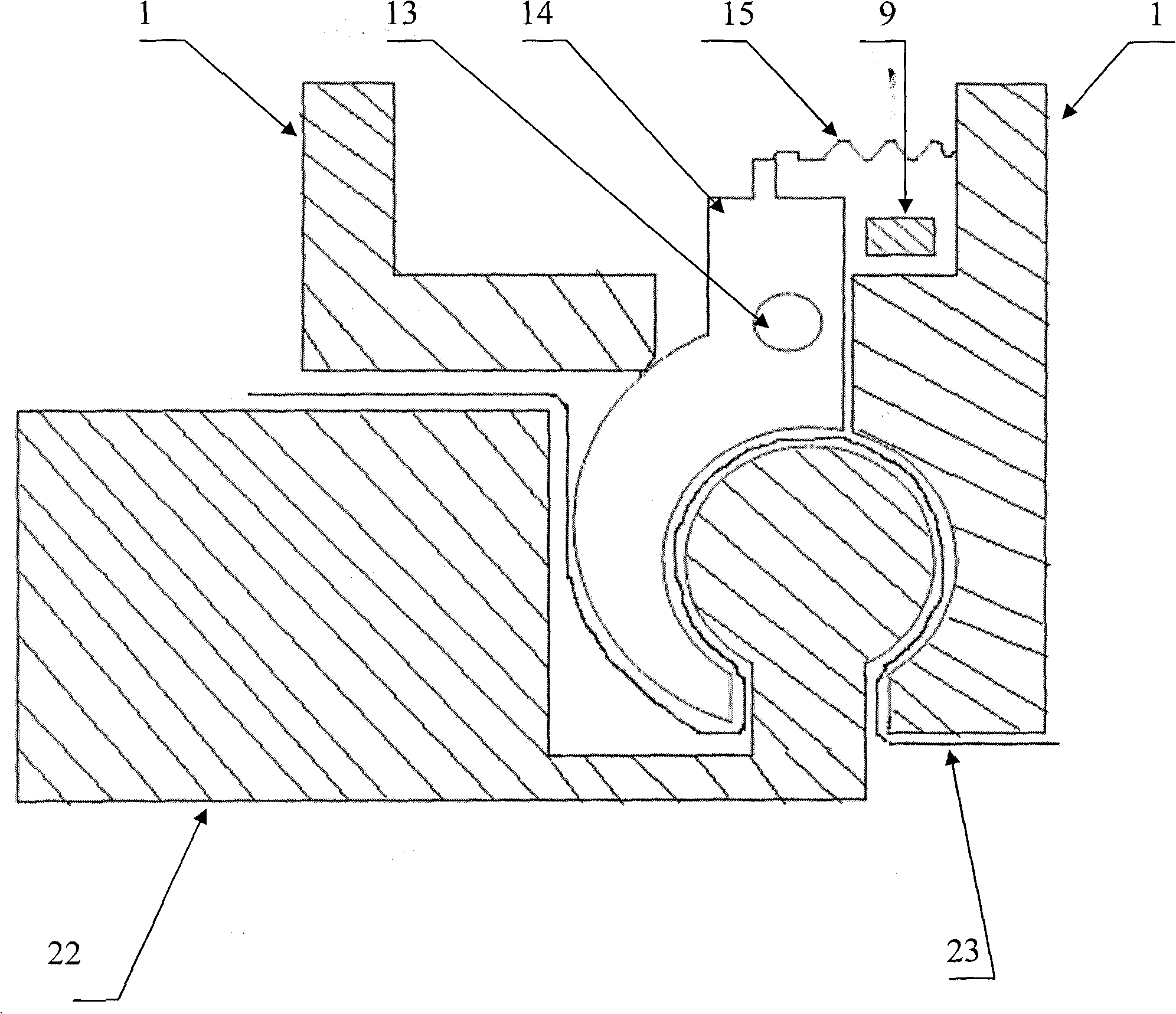

[0015] Embodiment: the cloth (23) passes between the embroidery frame (22), the clip housing (1) and the clamping pliers (14), and the clamping pliers (14) is pushed to tighten by the swing of the swing arm (9) and the distance between the clip housing (1) to achieve the purpose of clamping the cloth on the embroidery frame (22).

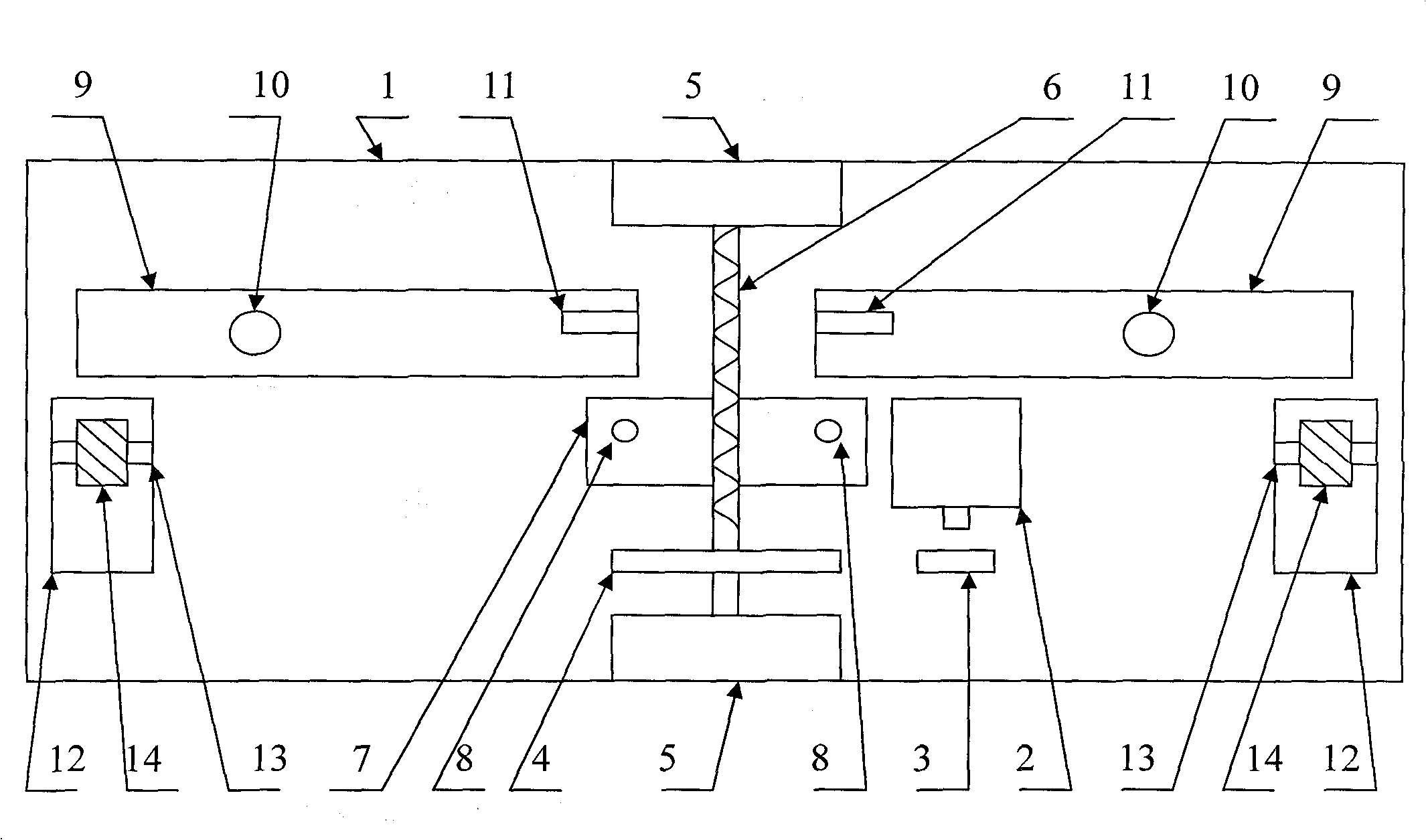

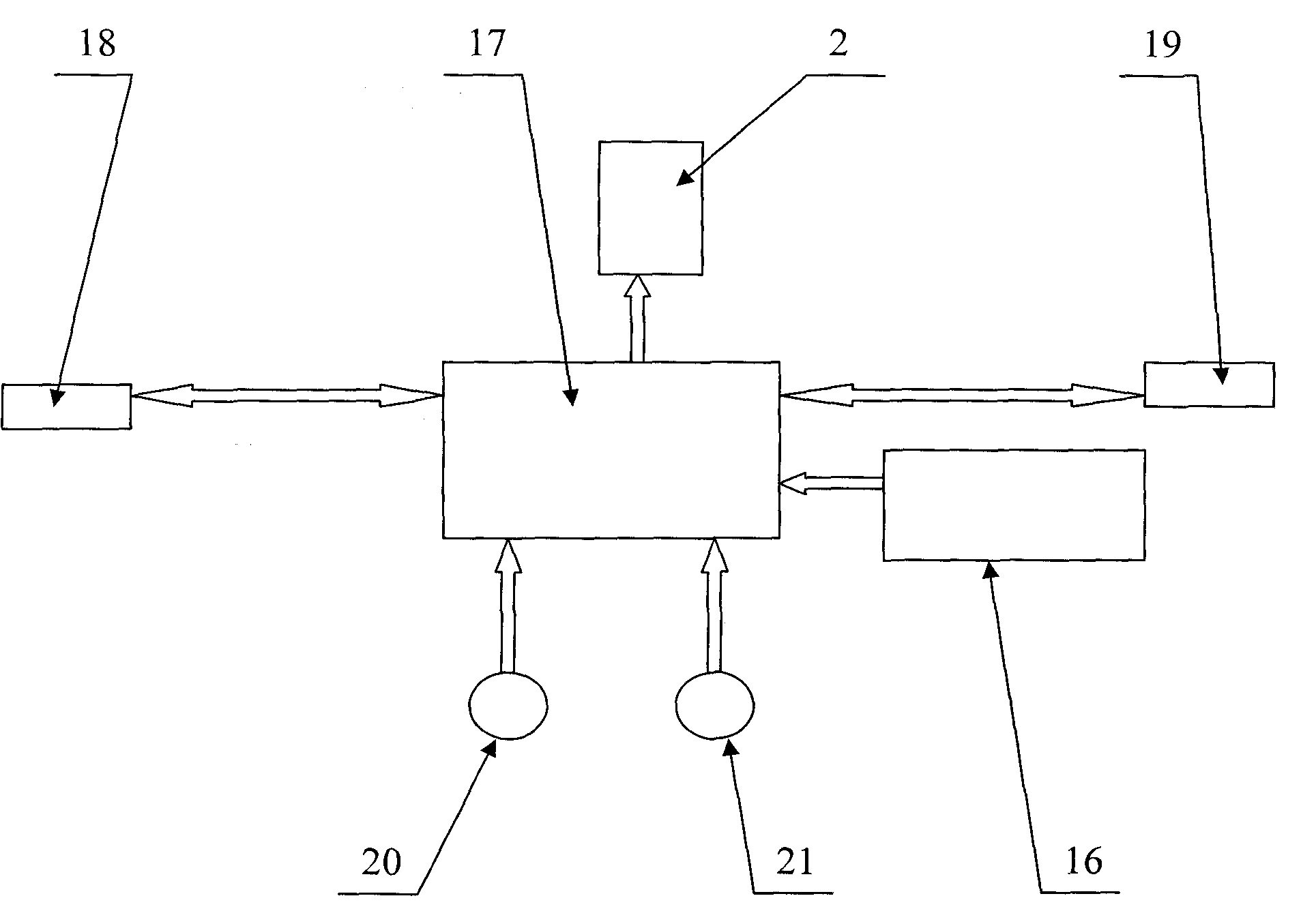

[0016] Such as figure 1 , figure 2 As shown, an automatic cloth clip for an embroidery machine, its actuator includes: a clip housing (1), a motor (2), a driving gear (3), a transmission gear (4), a support seat (5), a transmission wire Bar (6), sliding block (7), toggle column (8), swing arm (9), fulcrum shaft (10), toggle fork (11), press hole (12), clamping pliers Shaw shaft (13), clamping pliers (14), back-moving spring (15).

[0017] The upper part of the clamp housing (1) is fitted with all parts, the motor is installed in the middle of the clamp housing (1), and the driving gear (3) is fixed on the motor (2) and meshed with the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com