Water erosion test device

A test device, water erosion technology, applied in the direction of testing wear resistance, using repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of inability to achieve precise control of pressure and damage area, long test time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

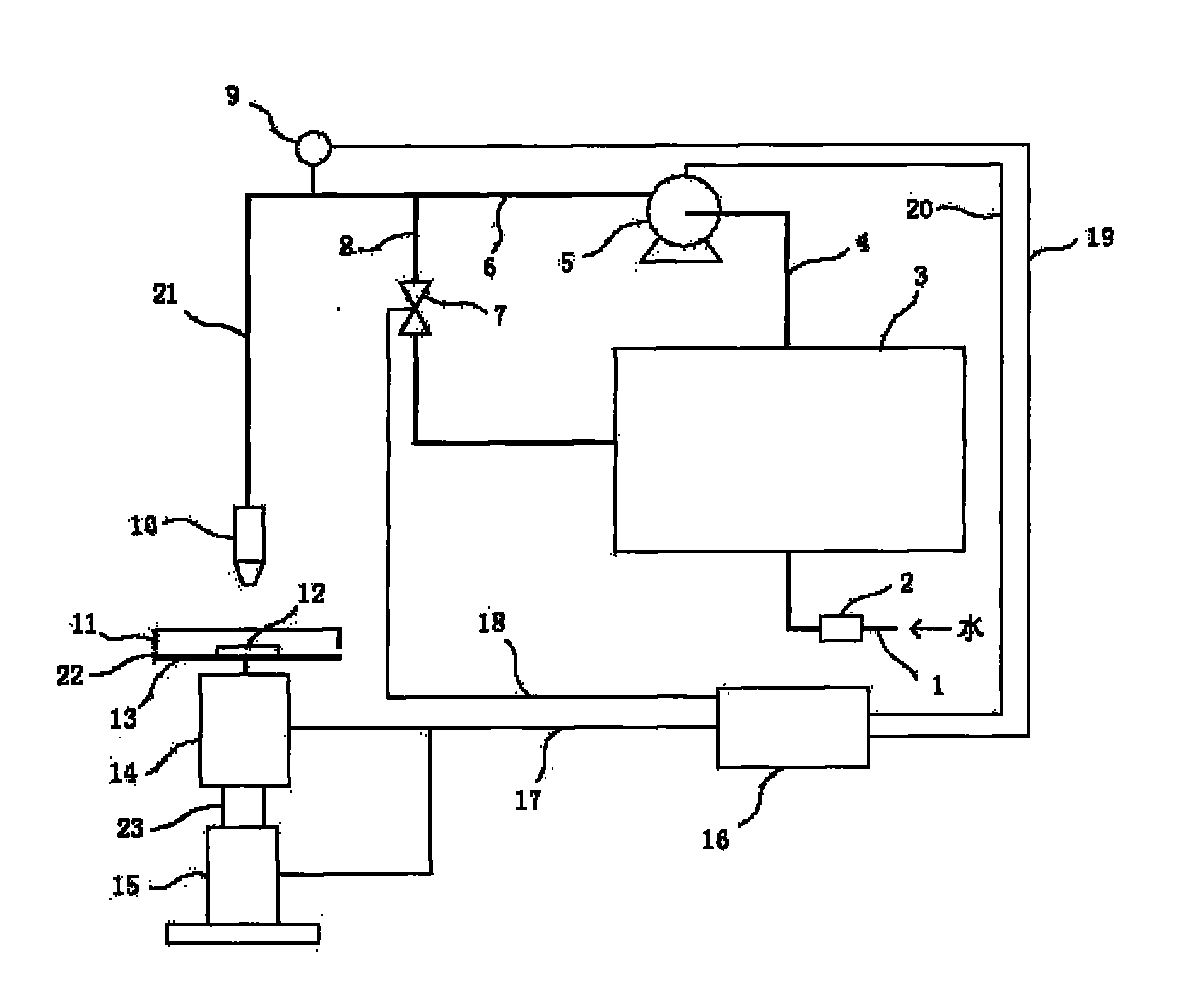

[0016] The structure of the present invention is as figure 1 As shown, it consists of a high-pressure pulse water jet device and a workpiece clamping table; the high-pressure pulse water jet device includes a water tank 3 and a water pump device 5, the water pump device 5 is connected to the water tank 3, and the water pump device 5 adopts a three-plunger pump. The outlet pipe 6 of the water device 5 is connected with a return pipe 8 and a jet pipe 21, the jet pipe 21 is equipped with a pressure gauge 9 and a nozzle 10, the return pipe 8 is connected with the water tank 3, and the return pipe 8 is provided with an electric pressure relief valve 7; The workpiece clamping table includes a turntable 13 provided with clamps 12, the periphery of the turntable 13 is provided with a glass edge 11, and the lower half of the glass edge 11 has a drain hole 22 with a diameter of 2mm, and the turntable 13 is installed on the motor 14, and the motor 14 is contained on the lifting device 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com