Method for measuring alignment accuracy of machine vision system

A technology of machine vision system and alignment accuracy, which is applied in the direction of measuring devices, instruments, photoplate making process of patterned surface, etc. It can solve the problems that the accuracy measurement cannot reflect the situation of all CCD surfaces, and the accuracy measurement is mixed with other factors. Achieve the effect of reducing human interference and accurate precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings. For convenience of description and highlighting of the present invention, relevant components existing in the prior art are omitted from the drawings, and the description of these well-known components will be omitted.

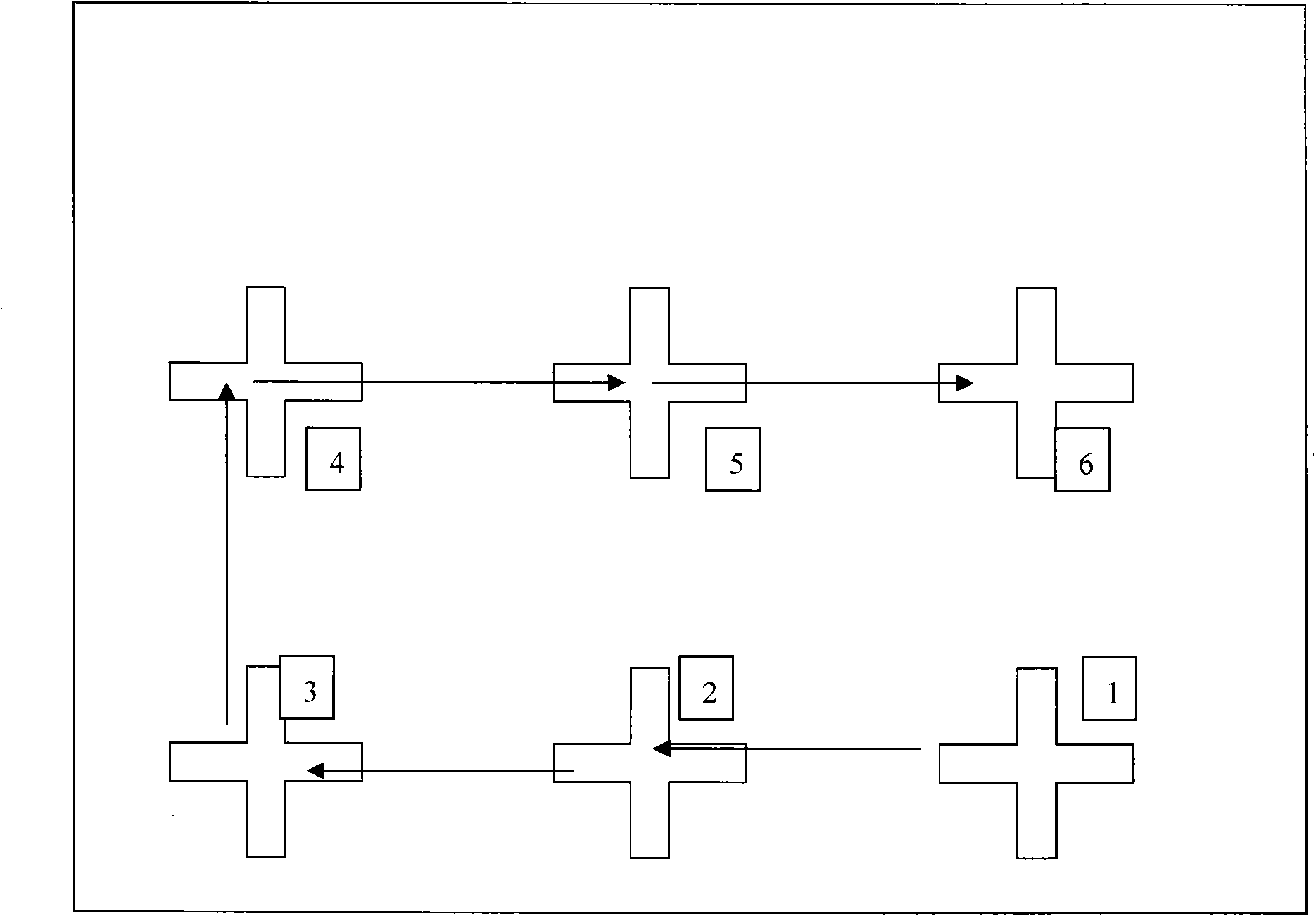

[0027] The present invention uses a marked substrate, see image 3 Schematic diagram of the labeled substrate shown. Several identical marks are evenly distributed on the marked substrate, and the positions and intervals of the marks are precisely measured and known; the stationary marked substrate is photographed by a machine vision system to obtain an image, and the image is subjected to graphic analysis ( The steps include but are not limited to: image segmentation, edge detection, centroid algorithm), and the pixel positions of each marker image in the field of view can be obtained. see Figure 4 The graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com