Molding device used for preparing mine milltailings filling check blocks and check block preparation method

A test block and mine technology, applied in the field of mine backfill testing devices, can solve the problems of inability to meet standard test block production requirements, distortion of strength test results, uneven distribution of test blocks, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

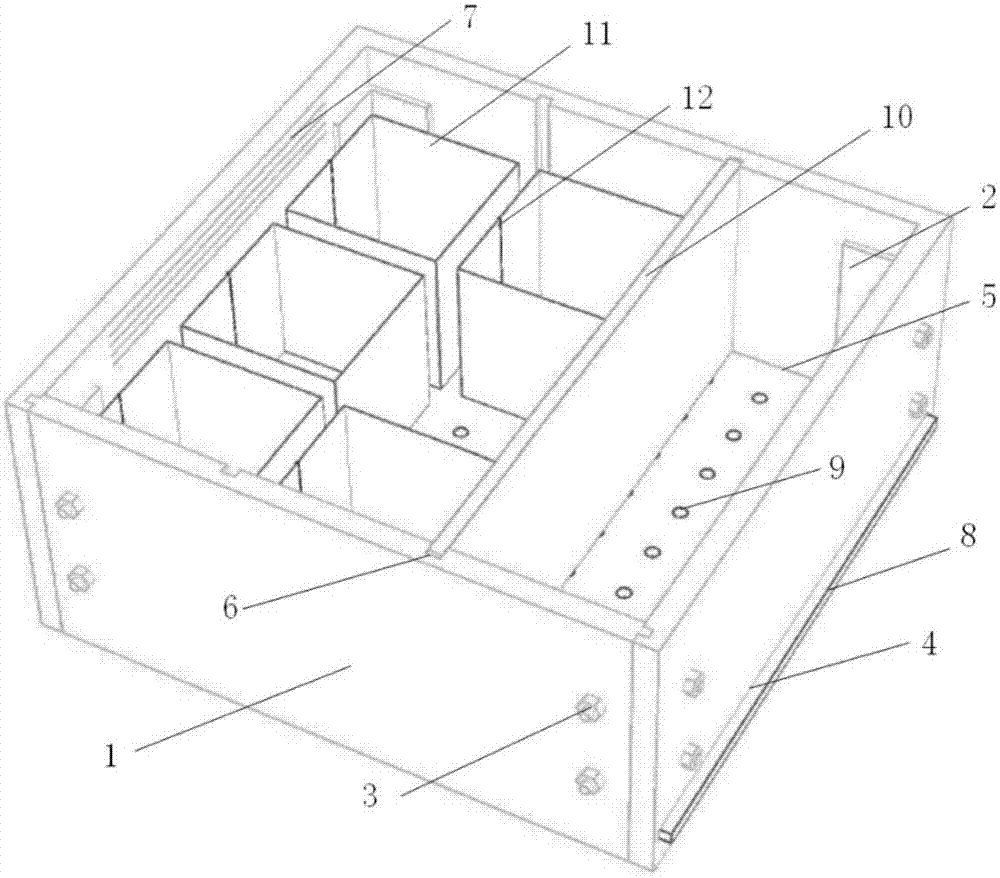

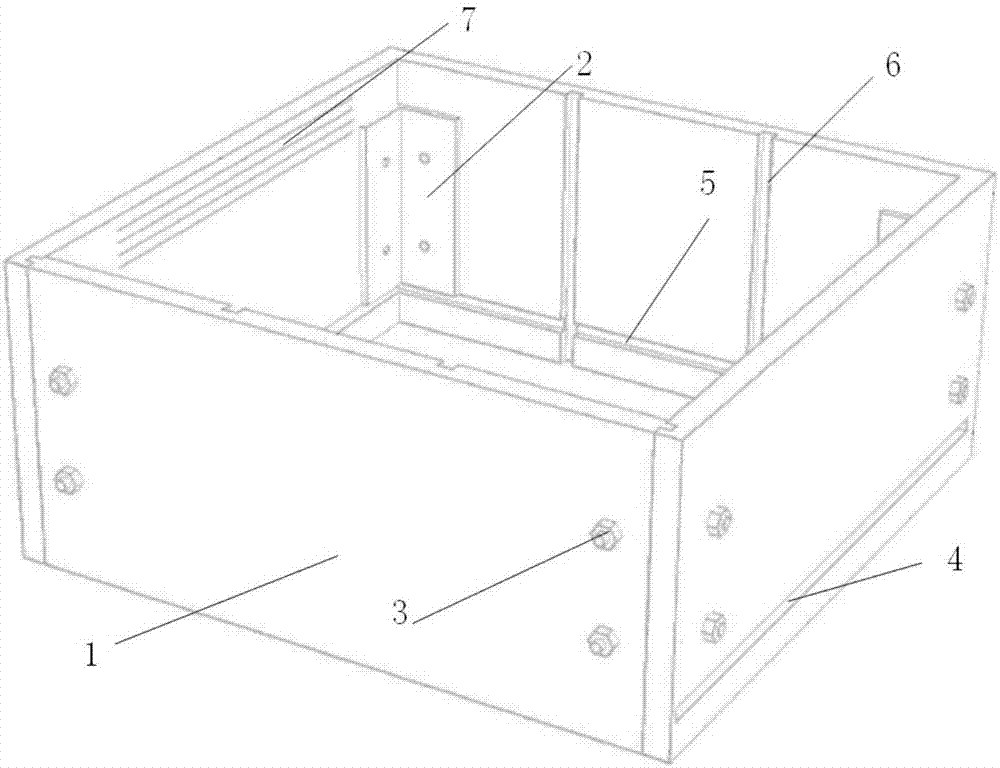

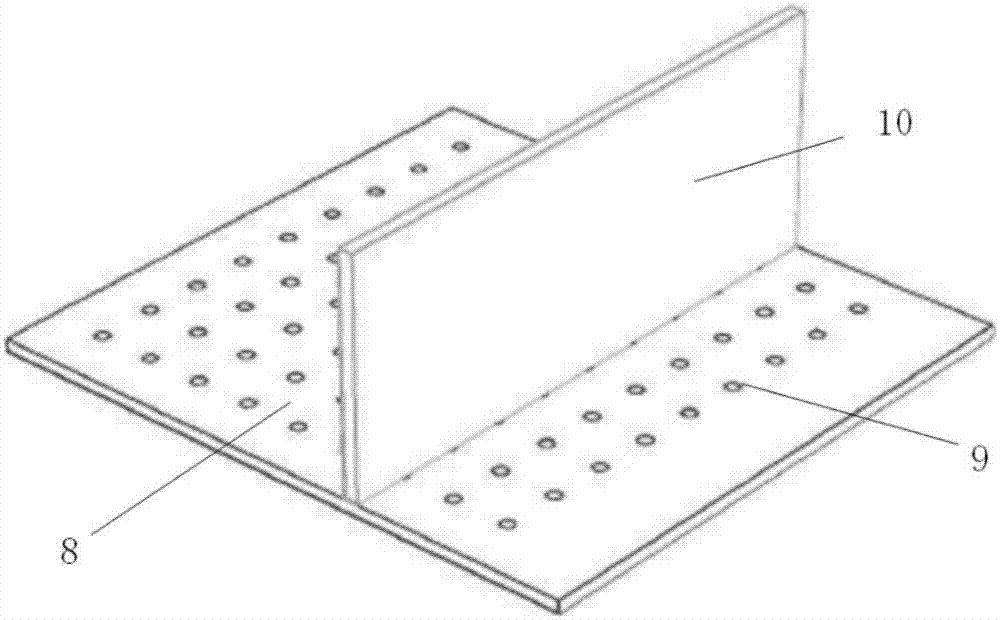

[0046] Such as figure 1 As shown, this embodiment is used to make a high-concentration mine tailings filling test block device, including a box-shaped frame 1 , a permeable bottom plate 8 , an isolation baffle 10 and a forming mold 11 . The mine filling slurry is injected into the box frame 1, and after free leveling or auxiliary leveling, the tubular mold 11 is vertically inserted into the slurry, and a certain distance is kept between the molds to avoid mutual interference. The invention does not need a glass rod tamping link, minimizes human interference in the pouring process of the filling slurry, improves the regularity of the test block, has simple and easy standardization of the test method, and effectively improves the accuracy of the strength test of the filling test block.

[0047] The preparation method of the test piece of the embodiment of the present invention comprises the following steps:

[0048] (1) According to the test plan, determine the permeable bottom...

Embodiment 2

[0056] Such as Figure 5 As shown, this example is used to simulate the distribution law of the strength of the filling body at different positions from the discharge port after the high-concentration mine tailings (including coarse aggregate) filling slurry is freely leveled from one end of the stope. The device includes a box-shaped frame 1 , a permeable bottom plate 8 , a storage funnel 15 , a discharge pipe 16 and molding dies 11 and 13 . The mine filling slurry is injected into the material storage funnel 15 and freely flows into the box body through the discharge pipe 16 . After free leveling, insert the tubular molds 11 and 13 vertically into the slurry, keep a certain distance between the molds and the wall surface, and the molds to avoid mutual interference, and demould after curing. Mark the insertion position for each mold, maintain it to a specified age, and measure its compressive strength. The present invention does not need the glass rod tamping link, avoids t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com