Damper for 1000kV extra-high voltage alternative-current transmission line

A UHV AC and power transmission line technology, applied in cable suspension devices, mechanical vibration damping devices, etc., can solve the problems of difficult to eliminate water and ice deposition, bulky shape, tip discharge, etc., to achieve reliable performance, avoid tip discharge, The effect of increasing the specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

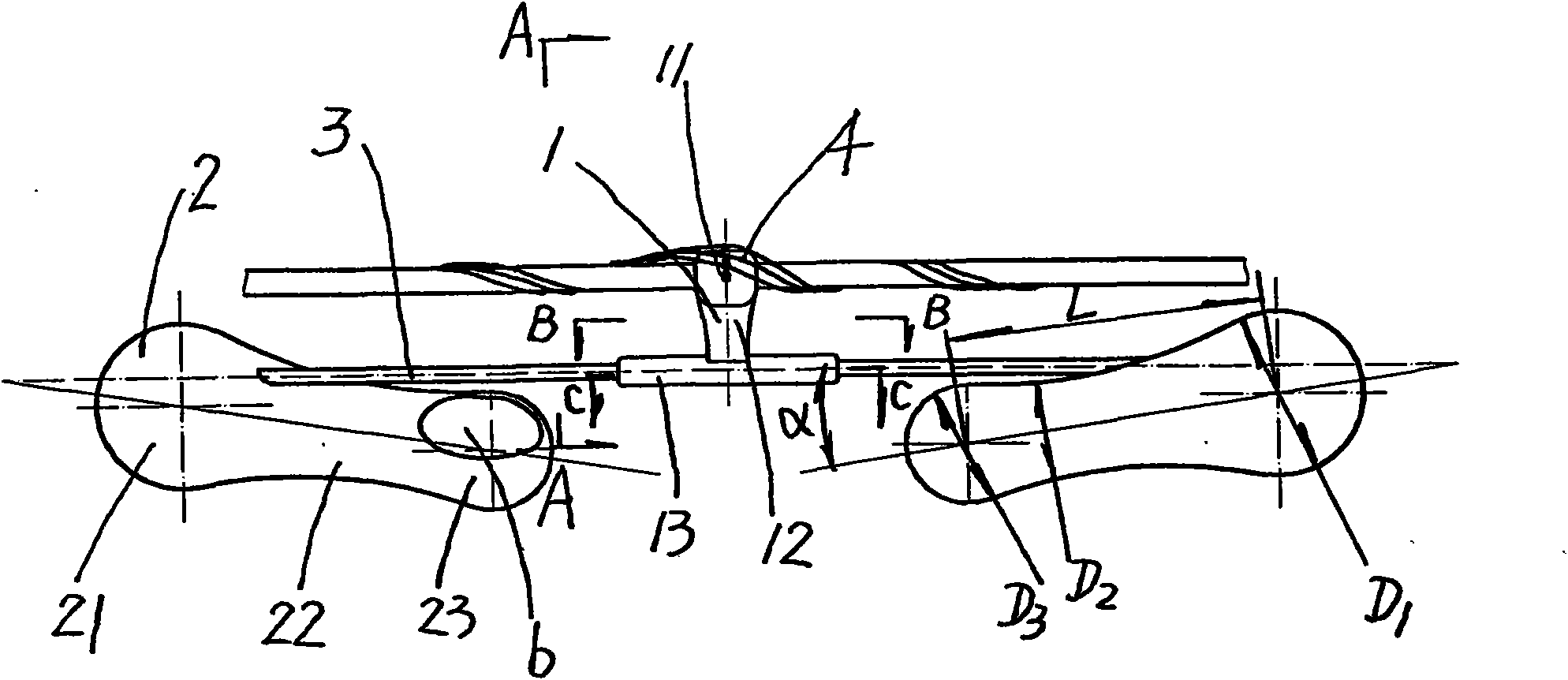

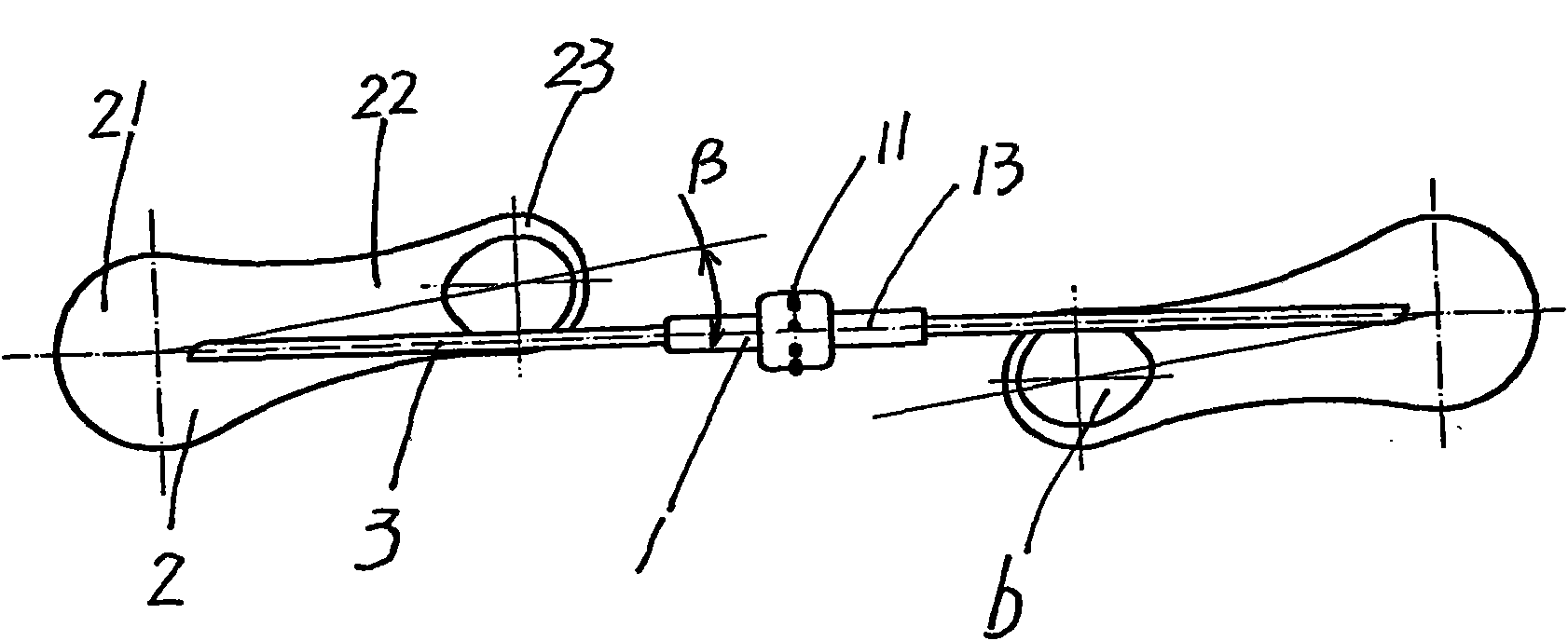

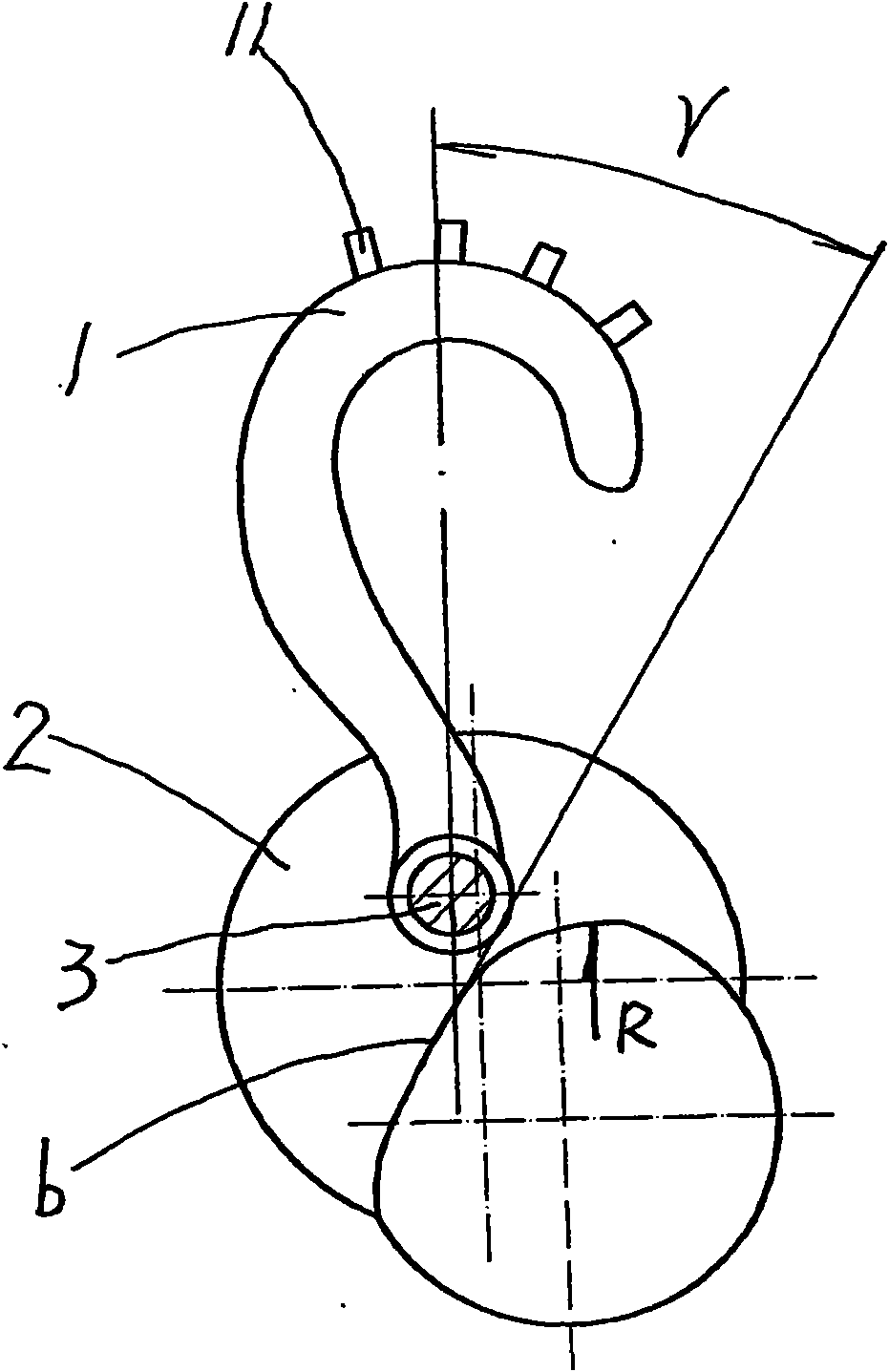

[0018] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , the 1000kV UHV AC transmission line anti-vibration hammer of the present invention is composed of a wire clip 1, a hammer body 2, a steel strand 3, and at least one pre-twisted wire 4. The pre-twisted wire 4 of the present embodiment is three, and the wire clip 1 is fixedly connected with the steel strand 3, and the two hammer bodies 2 are respectively fixed at both ends of the steel strand 3, and the pre-twisted wire 4 is used to fix the wire clamp 1 on the transmission line, and the wire clamp 1 is Hippocampus-shaped structure, the fixed conduit 13 and the steel strand 3 are fixedly connected in an arc-shaped structure, the wire clip 1 is composed of separating nails 11, hooks 12, and fixing conduits 13, and 1 to 6 separating nails 11 They are respectively arranged on the top of the hook 12. There are four spacer nails 11 in this embodiment, and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com