Device and method for measuring the winding weight or winding thickness at the inlet of a carding machine

A cotton lap, measuring gap technology, used in textiles and papermaking, fiber processing, fiber feeding, etc., can solve problems such as jamming, and achieve the effect of reducing inertia, effective monitoring, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

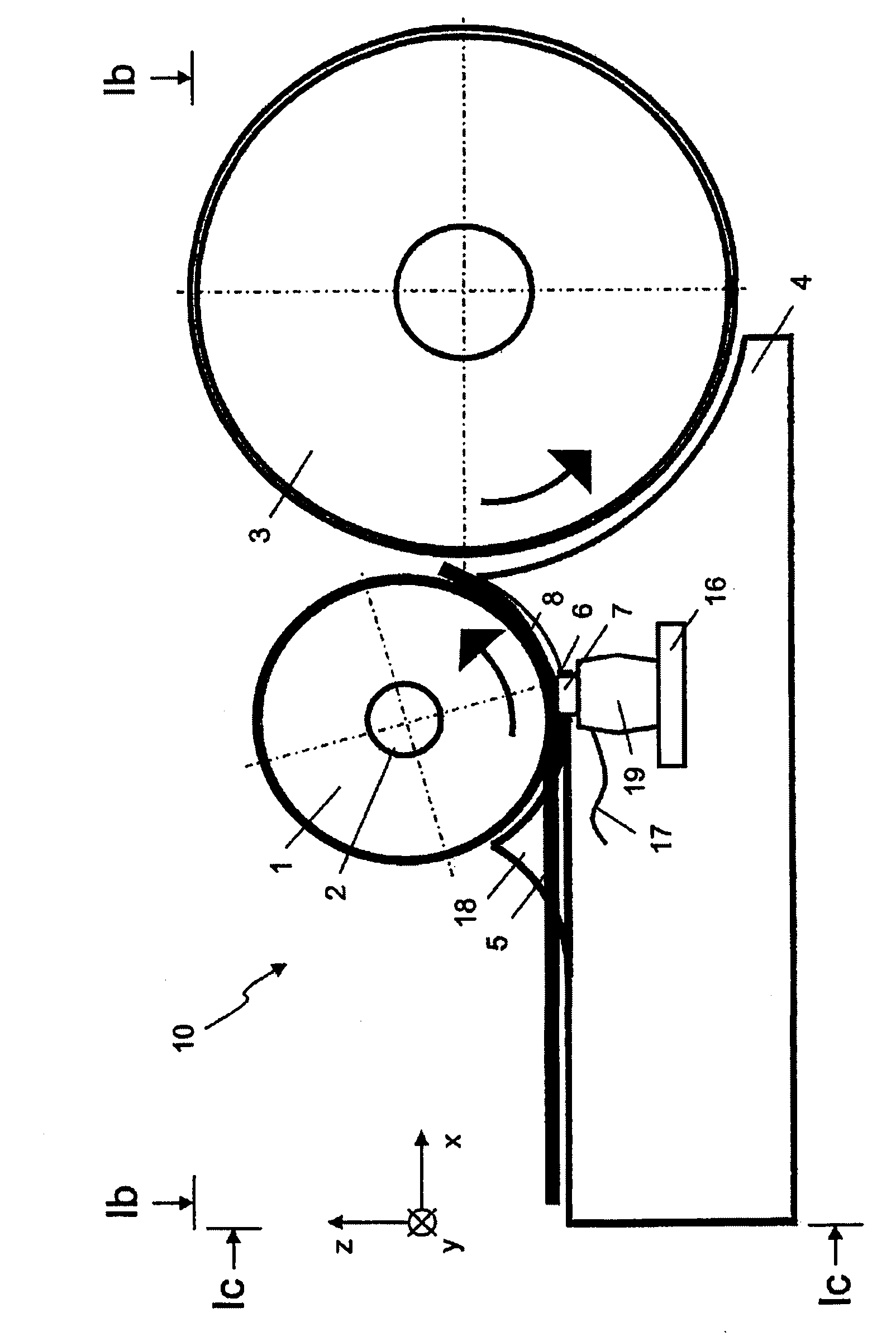

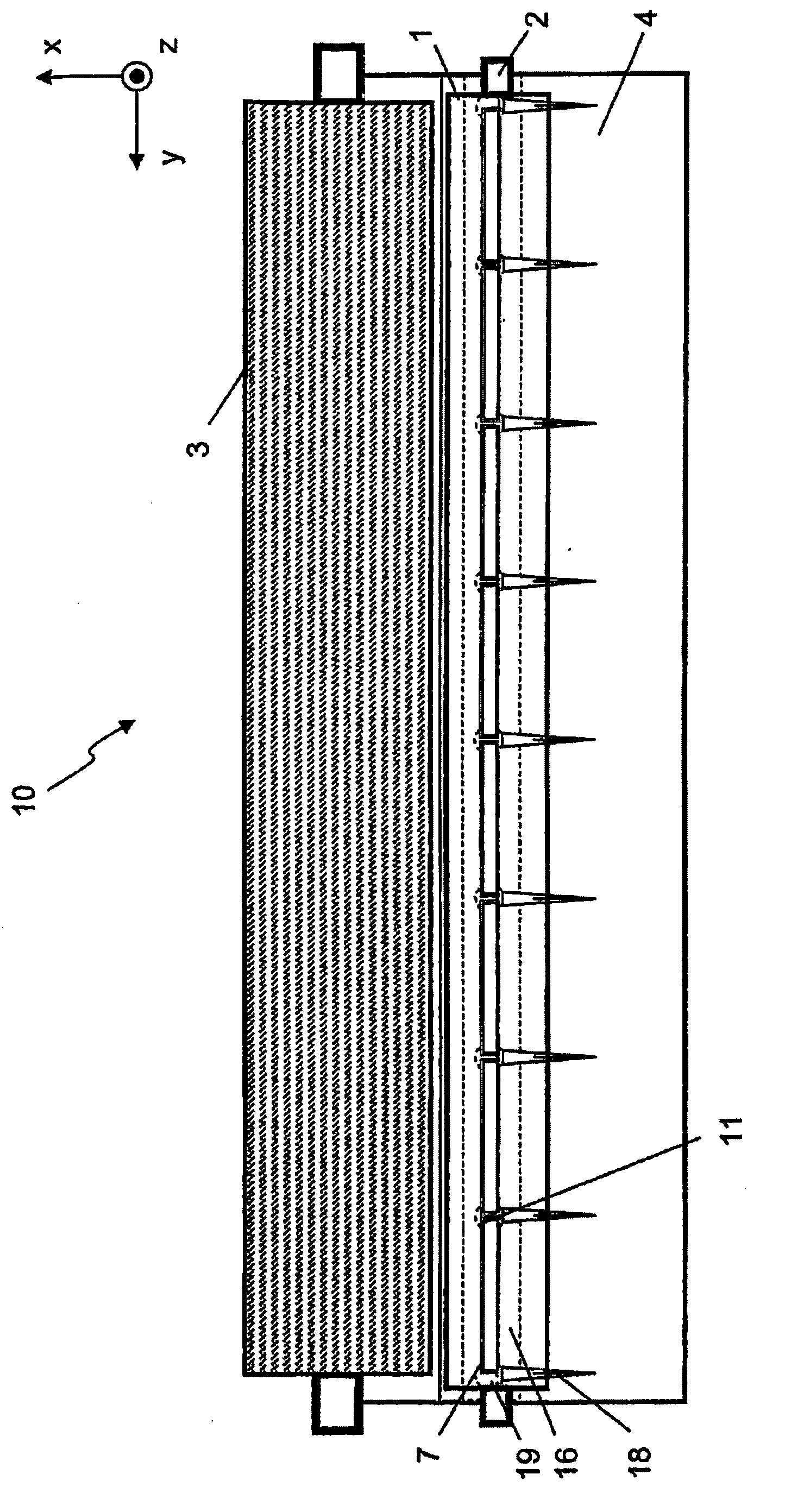

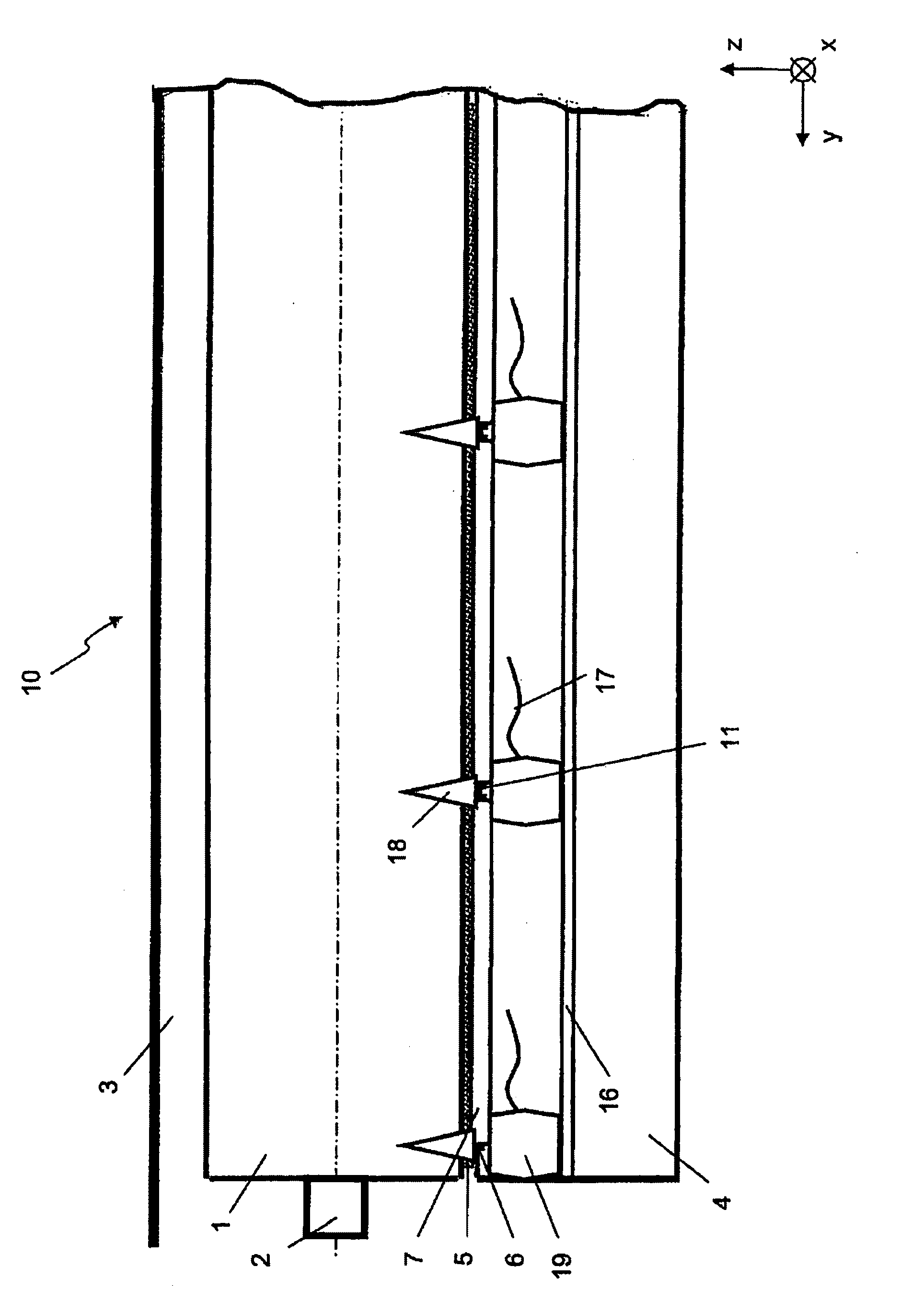

[0060] Figure 1 shows a preferred embodiment of the device 10 of the invention. The device 10 serves to measure the mass or thickness of a web-shaped or lap-shaped lap 5 moving in the x-longitudinal direction. It is usually located in the infeed section of the card where feed roll 1 and licker-in roll 3 are shown. (The feed roller 1 is shown in perspective in the view of Fig. 1(b) to clearly show the underlying components). The device 10 comprises a fixed rigid feeding plate 4 for guiding the lap 5 . The feed roller 1 is driven to rotate to deliver the lap 5 to the carding machine. The feeding roller 1 extends over the entire width (y-direction) of the feeding flat plate 4 . The shaft 2 of the cotton feeding roller 1 is set according to the cotton feeding flat plate 4, and a measuring gap 8 is created between the outer surface of the cotton feeding roller 1 and the guide rail surface of the cotton feeding flat plate 4, so that the cotton feeding flat plate 4 guides the cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com