Application of novel method for industrialized sterilization and disinfection treatment of edible mushroom cultivating material by utilizing microwave sterilization technology and sterilization device or system

A technology of microwave sterilization and sterilization, which is applied in the direction of disinfection, water supply equipment, sanitary equipment for toilets, etc., can solve the problems of low sterilization efficiency, impact on the output and quality of edible fungi, and high smoke and dust, and achieve energy saving The effect of environmental protection, economic and social benefits, good economic and social benefits, and high penetration depth

Active Publication Date: 2010-08-25

临沂高新文旅发展有限公司

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned sterilization technology not only has a longer sterilization time period, but also consumes a lot of coal and firewood energy, has a lot of smoke and dust, and causes great environmental pollution. Because the water is easy to dry out, it needs to be frequently added with water, which is labor-intensive. There are dead angles in the sterilization room, causing Incomplete sterilization results in infection of miscellaneous bacteria, low sterilization efficiency, and seriously affects the effect and output of sterilization, resulting in a serious impact on the output and quality of edible fungi and economic benefits

In addition, my country has gradually adopted microwave sterilization technology in industries such as food, medicine, tobacco leaves, building materials and medical treatment, and achieved good economic benefits, but there is no use of microwave sterilization device technology for sterilization of edible fungus culture materials. Disinfection reports

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

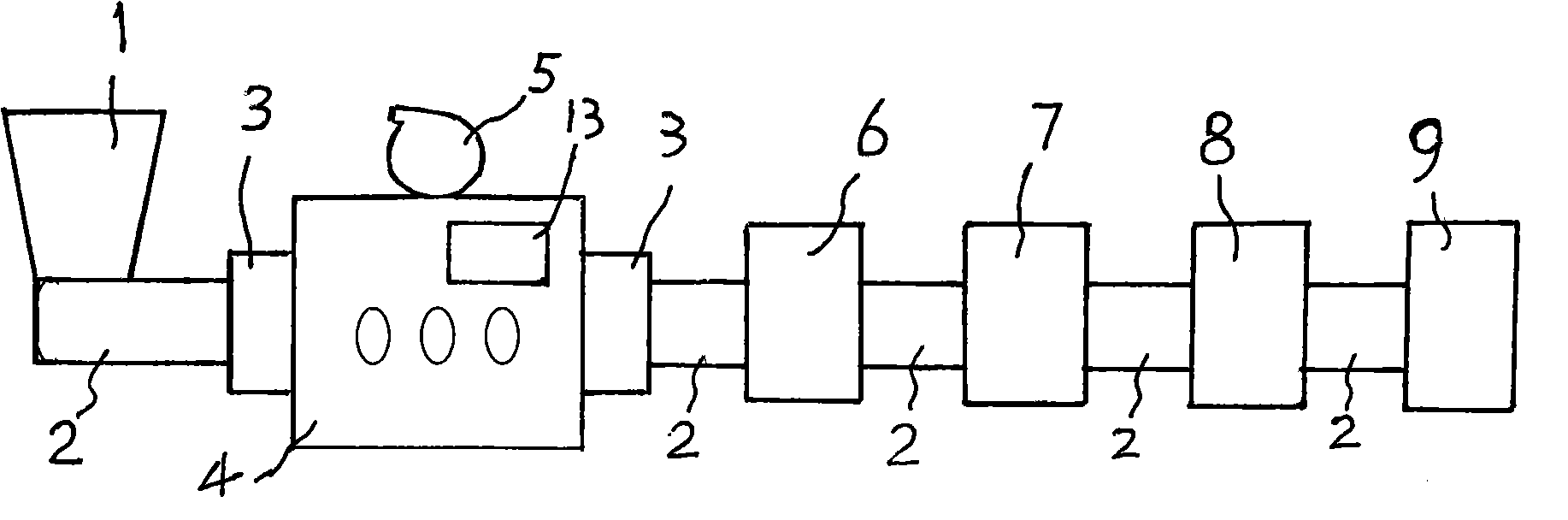

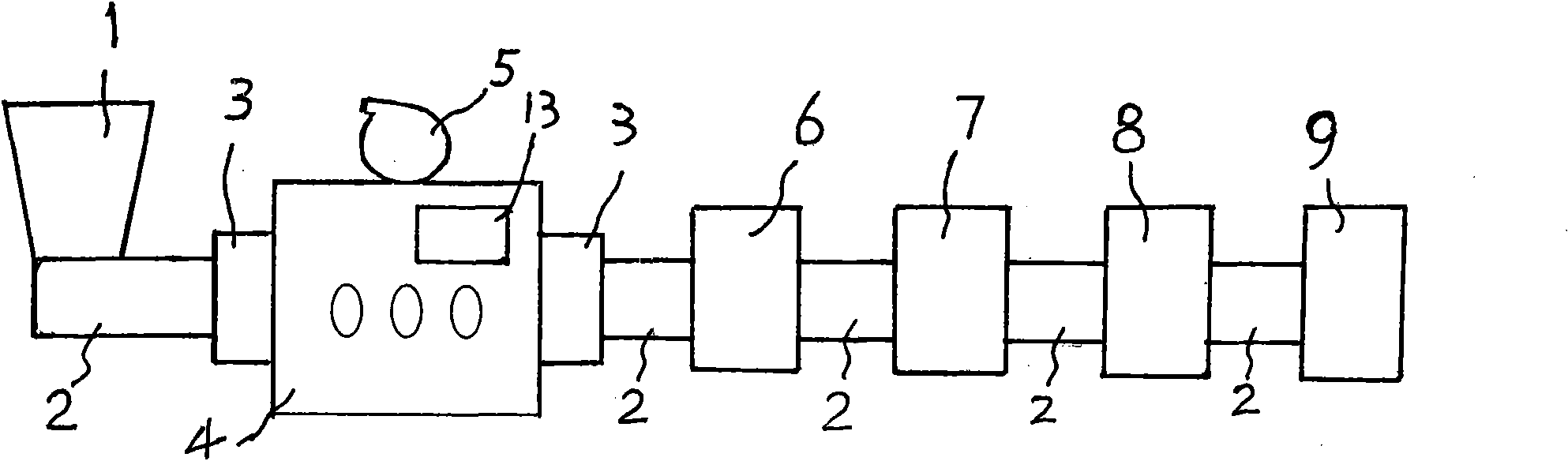

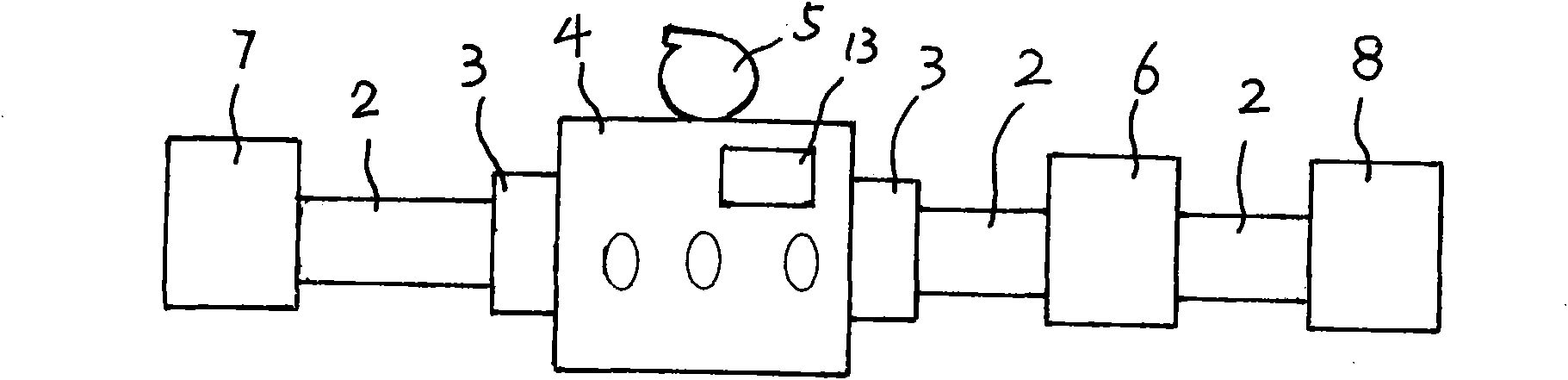

The invention discloses an application of a novel method for industrialized sterilization and disinfection treatment of edible mushroom cultivating materials by utilizing a microwave sterilization technology, and a sterilization device or system. The device or system is characterized in that a microwave sterilization tunnel arranged on a rack is utilized, a microwave sterilization device composed of anti-leakage devices arranged at the front and the back of the microwave sterilization tunnel and a material conveying mechanism is used for sterilization and disinfection treatment of the edible mushroom cultivating materials, and the edible mushroom cultivating materials can be unpackaged, or contained by material bags, material packets, material bottles or material baskets. The device or the system comprises the material conveying mechanism provided with a conveying belt, the microwave sterilization tunnel, a rapid cooling device, a strain inoculation device, the anti-leakage devices, microwave generators and an exhaust steam fan, wherein the microwave sterilization tunnel, the rapid cooling device and the strain inoculation device are arranged on the rack in sequence, the anti-leakage devices are arranged at the front and the back of the microwave sterilization tunnel, the microwave generators are arranged on both sides of the microwave sterilization tunnel, the exhaust steam fan is arranged on top of the microwave sterilization tunnel, and access ways capable of enabling the conveying belt to pass smoothly are arranged in the microwave sterilization tunnel, the anti-leakage devices arranged at the front and the back of the microwave sterilization tunnel and the cooling device. The invention can be utilized for the sterilization treatment of edible mushroom cultivating materials, and has the characteristics of rapid sterilization speed, high penetration depth, good sterilization effect, low cost, energy conservation and environment protection.

Description

Utilizing microwave sterilization technology as a new method, application and sterilization device or system for industrial sterilization and disinfection of edible fungus culture material (1) Technical field The invention relates to a production technology of edible fungi, in particular to a new method and application of using microwave sterilization technology as an industrial sterilization and disinfection treatment of edible fungus compost and a sterilization device or system (ie, a factory production line). (two), background technology At present, traditional sterilization methods for edible fungus compost include: 1. Use high-pressure steam to sterilize and sterilize. It needs to be kept for more than 2 hours at a temperature of 121° C. to achieve the ideal sterilization effect. 2. Use a steam oven or a steam room as a sterilization room for sterilization. When sterilizing, place the material bottles, material bags or material bags in an orderly manner with a certain ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61L2/12A61L2/24

Inventor 涂选来涂宇龙

Owner 临沂高新文旅发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com