Bronzing machine roller-increasing device

A hot stamping machine and hot stamping plate technology, applied in the field of machinery, can solve problems such as restricting product upgrades, running out of printing, affecting product quality, etc., and achieve the effect of reducing production costs and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

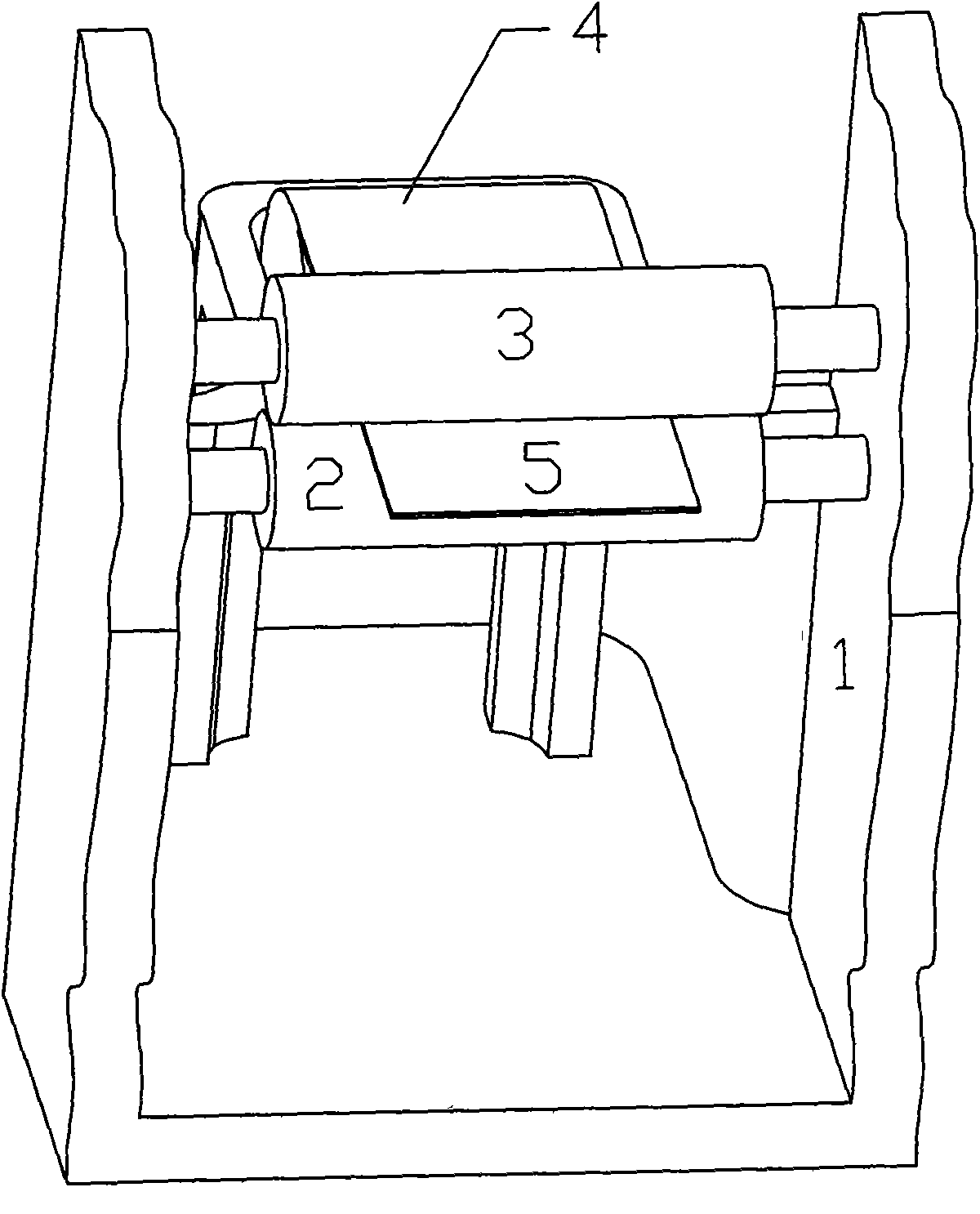

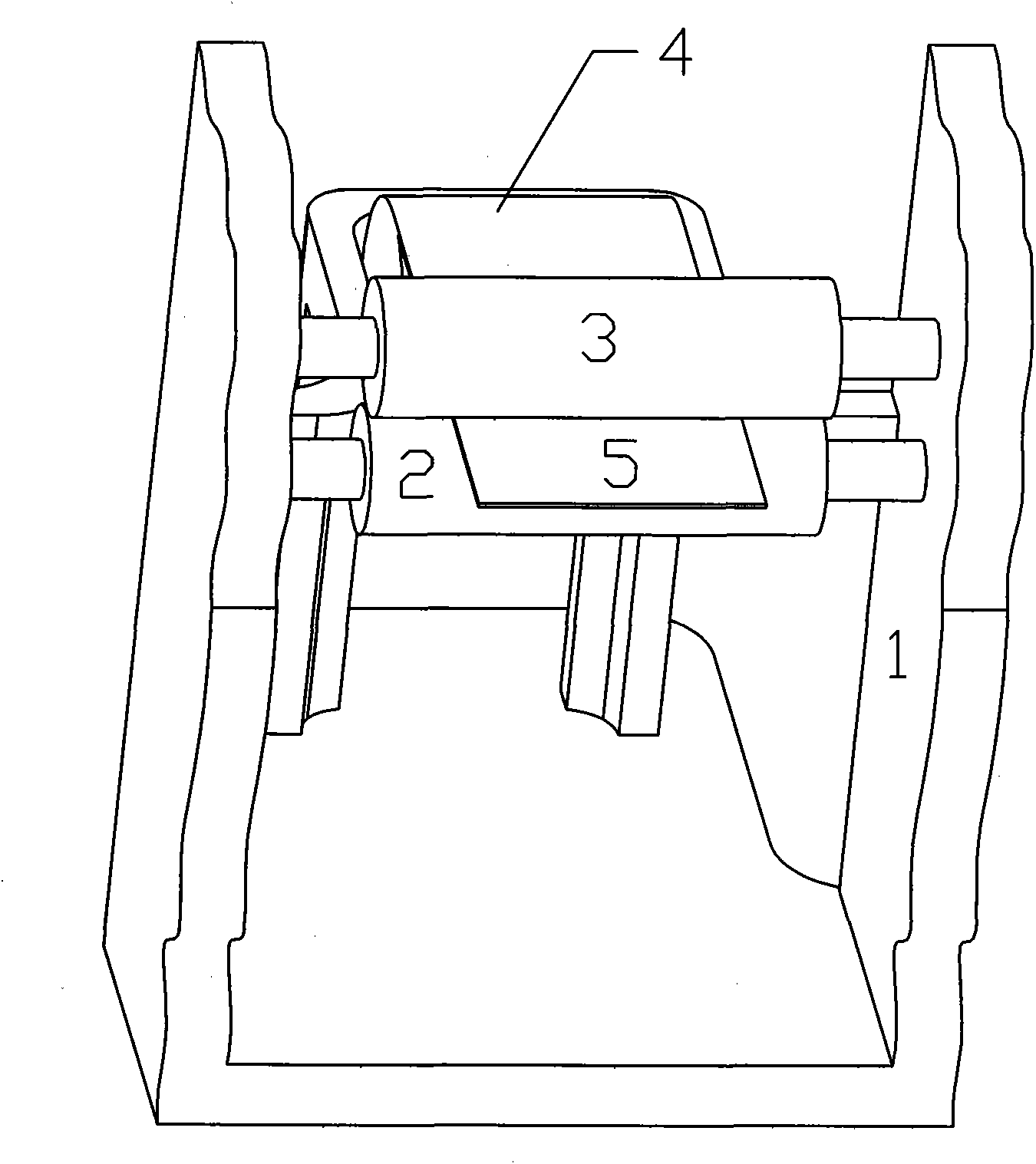

[0012] The hot stamping machine roll increasing device, the front end of the hot stamping machine body 1 is the fixing and feeding part of the unwinding paper 4; the hot stamping machine rolling increasing device includes the hot stamping machine body 1, a single plate 2 and a rubber roller 3, and is characterized in that: The smooth roller plate 2 and the rubber roller 3 are fixed on the front of the hot stamping machine body 1, and the rubber roller 3 is fixed on the upper part of the smooth roller plate 2; the diameter of the smooth roller plate 1 is 1 to 10 wires smaller than the diameter of the hot stamping plate; The surface is smooth.

[0013] During work, the paper tape 5 passes between the bachelor plate 2 and the rubber roller 3, and the bachelor plate 2 and the rubber roller 3 clamp the paper tape 5. Since the diameter of the bare roller plate 2 is 1 to 10 w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap