Late transition metal catalyst for olefin polymerization and preparation method thereof

A post-transition metal and olefin polymerization technology, which is applied in the field of olefin polymerization catalysts and its preparation, can solve the problems of unsatisfactory effect and low number average molecular weight of polypropylene, and achieve the goal of increasing number average molecular weight and isotacticity and improving polymerization activity Effect

Active Publication Date: 2010-08-25

PETROCHINA CO LTD

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing post-transition metal catalysts are still unsatisfactory for the polymerization of propylene, and the number-average molecular weight of the prepared polypropylene is relatively low (the number-average molecular weight is not more than 15000), and the isotacticity is lower than 70% (Small B.L., BrookhartM. "Polymerization of Propylene by a New Generation of Iron Catalysts: Mechanisms of ChainInitiation, Propagation, and Termination", Macromolecules, 1999, 32: 2120-2130; Zhu Yong, Xu Wei, Luo Zhenghong. Application of Catalysts in Propylene Polymerization", Industrial Catalysis, 2008, 16: 45-49.)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

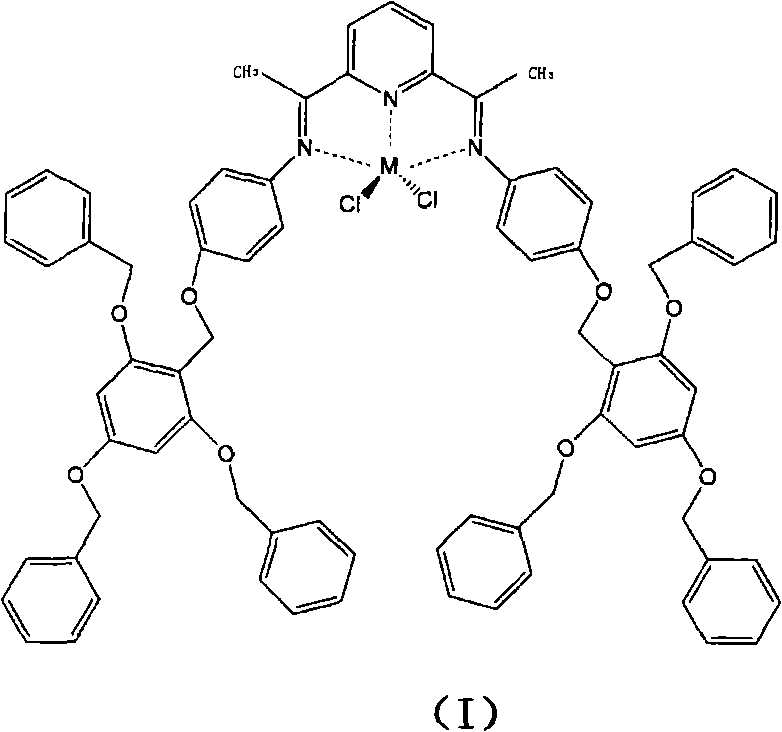

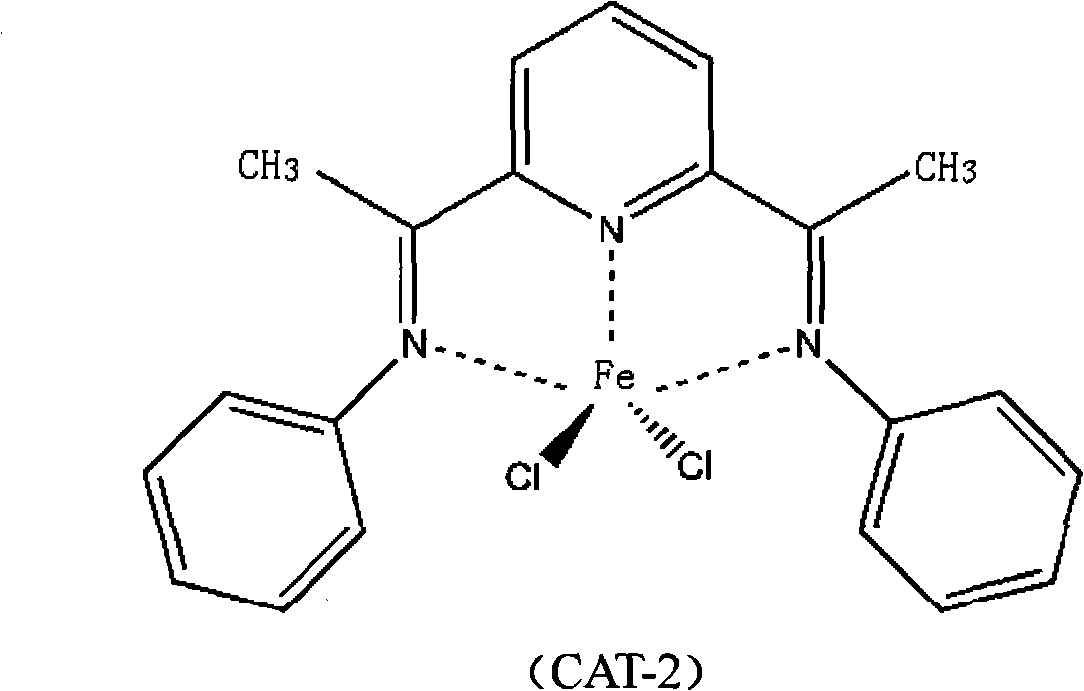

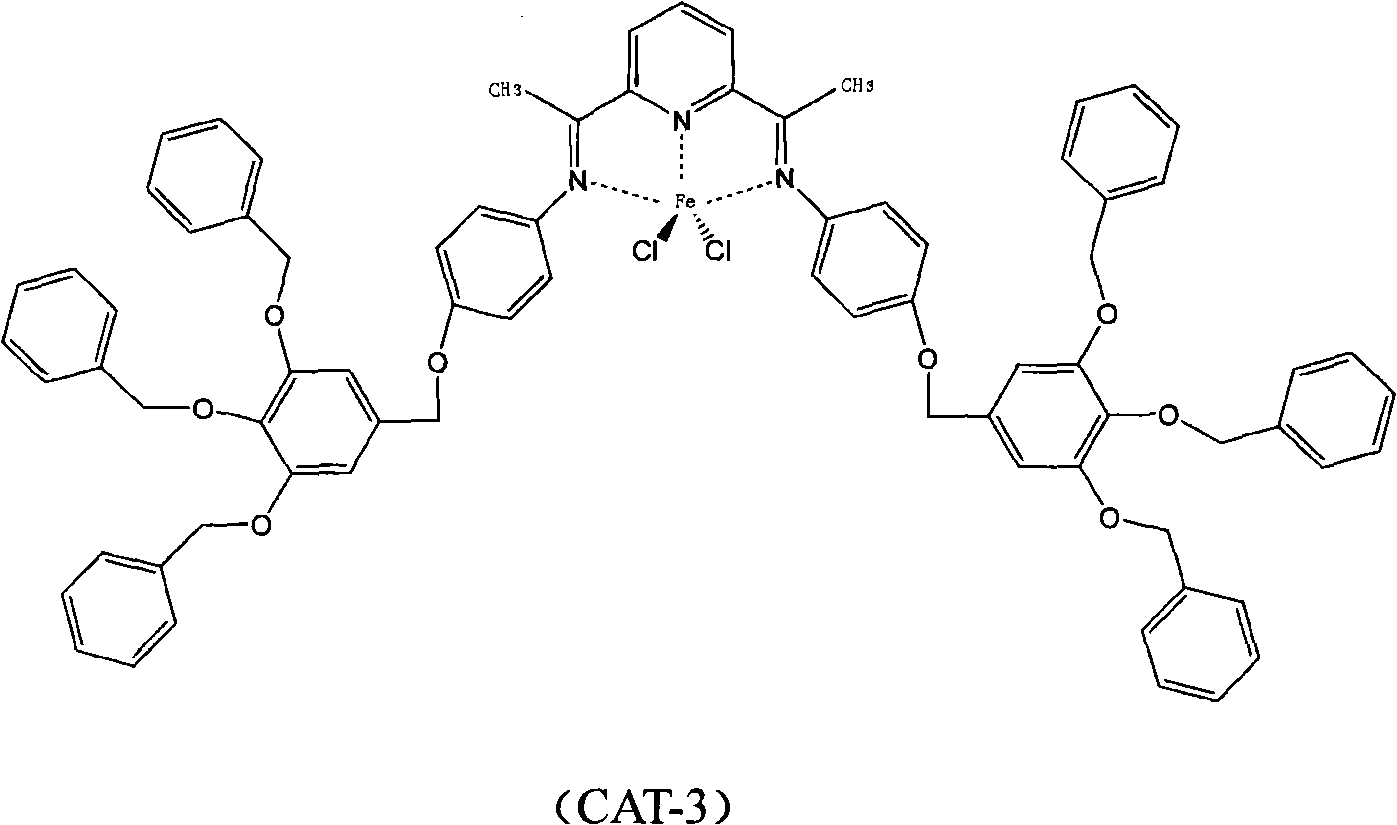

The invention provides a late transition metal catalyst for olefin polymerization with a structural formula (I), which is characterized by introducing a wedge-shaped dendritic molecule having certain space volume and more symmetrical spatial position of substituent into a ligand structure, successfully avoiding chain transfer reaction of propylene and effectively preventing the propylene from attacking the active site from the side chain. When the catalyst for the olefin polymerization is used for propylene polymerization together with an aluminium alkyl compound, the polymerization activity is remarkably improved, the activity of the catalyst can reach 105g polypropylene / mol Fe*h, and in particular, the number-average molecular weight and degree of isotacticity of the polymerization product are enhanced. The number-average molecular weight is far more than 15000g / mol, and the degree of isotacticity is close to 85%. M is a transition metal selected from Fe, Co or Ni.

Description

technical field The invention relates to an olefin polymerization catalyst and a preparation method thereof, in particular to a late transition metal propylene polymerization catalyst containing pyridinediimine wedge-shaped dendritic ligands and a preparation method thereof. Background technique In recent years, late transition metal catalysts represented by nickel, iron and cobalt series have shown quite high activity in ethylene polymerization, and thus become one of the important members in the field of polyolefin catalysts. There are many literature reports on late transition metal catalysts and their homo(co)polymerization of ethylene. Such as literature 1 (Adnan S, Abu-Surrah, Kristian Lappalainen, Ulla Piironen, et al. "Newbis (imino) pyridine-iron (II) and cobalt (II)-based catalysts: synthesis, characterization and activity towards polymerization of ethylene", Journal of Organometallic Chemistry, 648(2002): 55-61.), Document 2 (Ivanchev S.S., Tolstikov G.A., Badaev...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F4/80C08F10/00

Inventor 朱博超罗正鸿贾军纪孙卫国韦少义姚培洪徐人威杨战军许云波郝萍宋赛楠刘强王霞

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com