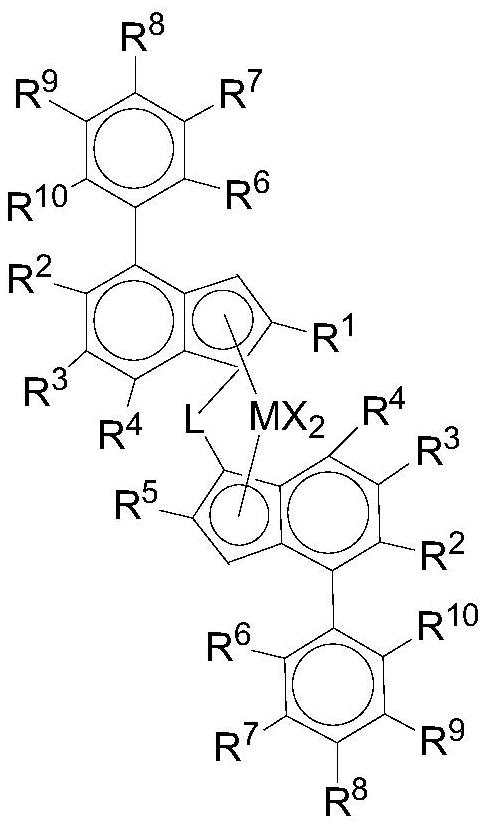

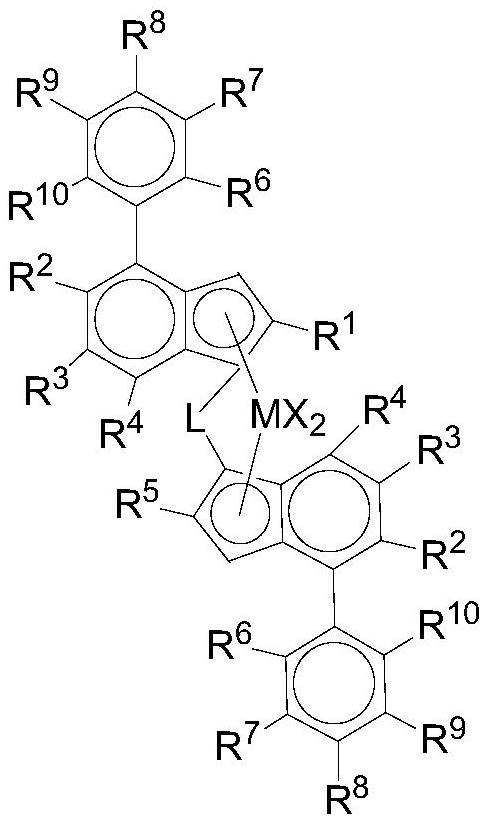

Preparation method of metallocene polypropylene catalyst

A metallocene polypropylene and metallocene compound technology, applied in the field of preparation of metallocene polypropylene catalysts, can solve the problems of limiting industrial applications and increasing the production cost of polypropylene products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

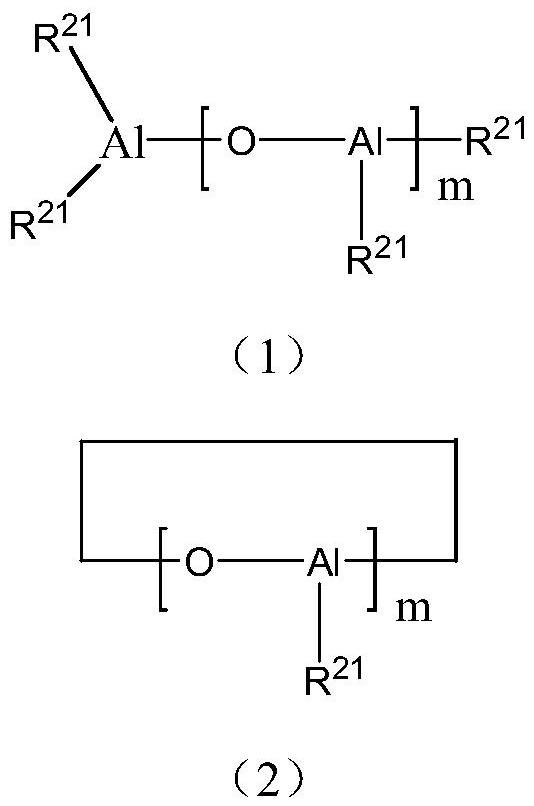

Method used

Image

Examples

Embodiment 1

[0049]In the catalyst preparation bottle under the protection of nitrogen, add 27mmol MAO toluene solution (10wt%), then add 34.7mg dimethylsilyl bis(2-methyl-4-phenylindenyl) zirconium dichloride, use ultrasonic For treatment, the ultrasonic frequency is 20KHz and the mixture is stirred for 2h at room temperature. Add 1g of silica gel pretreated at 600℃ and 20mL of toluene accurately weighed into the catalyst preparation bottle, stir at 50℃ for 2h, wash the solid part with 20mL of toluene 3 times, remove the solvent at room temperature to obtain the supported catalyst CAT4.

Embodiment 2

[0051]In the catalyst preparation bottle under the protection of nitrogen, add 27mmol MAO toluene solution (10wt%), then add 34.7mg dimethylsilyl bis(2-methyl-4-phenylindenyl) zirconium dichloride, use ultrasonic For treatment, the ultrasonic frequency was 40KHz and the mixture was stirred at room temperature for 2h. Add 1g of silica gel pretreated at 600℃ and 20mL of toluene accurately weighed into the catalyst preparation bottle, stir at 50℃ for 2h, wash the solid part with 20mL of toluene 3 times, and remove the solvent at room temperature to obtain the supported catalyst CAT5.

Embodiment 3

[0053]In the catalyst preparation bottle under the protection of nitrogen, add 27mmol MAO toluene solution (10wt%), and then add 34.7mg dimethylsilyl bis(2-methyl-4-phenylindenyl) zirconium dichloride, using ultrasound For treatment, the ultrasonic frequency is 60KHz and the mixture is stirred for 2h at room temperature. Add 1g of silica gel pretreated at 600℃ and 20mL of toluene accurately weighed into the catalyst preparation bottle, stir at 50℃ for 2h, wash the solid part with 20mL of toluene 3 times, remove the solvent at room temperature to obtain the supported catalyst CAT6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com