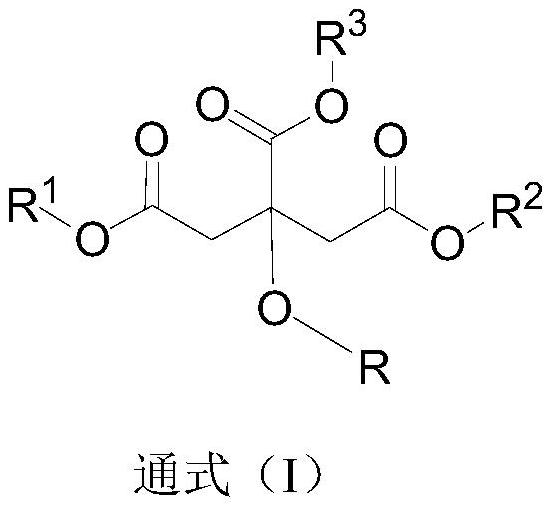

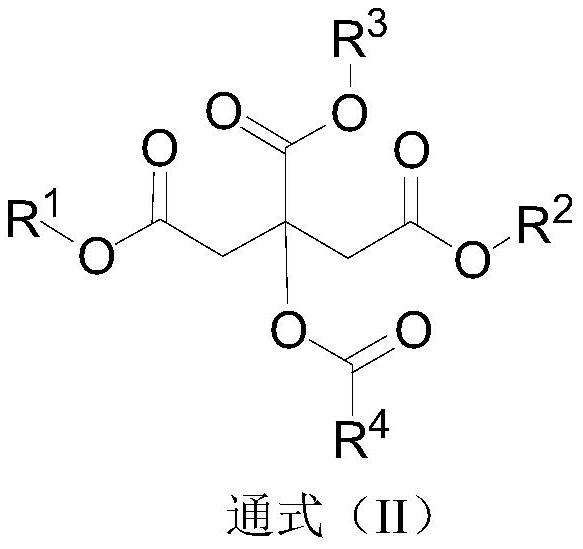

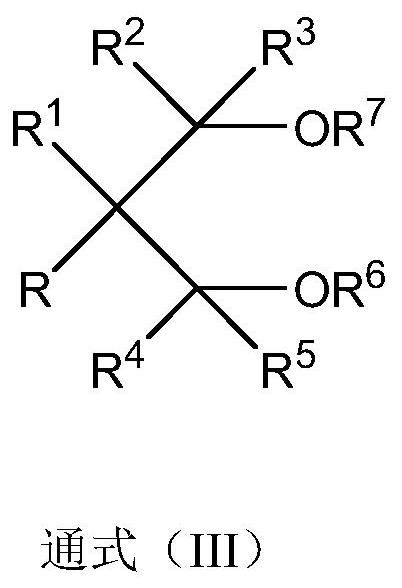

A kind of solid catalyst component for olefin polymerization, catalyst and application thereof

A solid catalyst, olefin polymerization technology, applied to solid catalyst components, in the application field of propylene polymerization reaction, can solve the problems of increasing the amount of internal electron donor, material waste, loss of internal electron donor, etc., to reduce internal The effect of electron donor dosage, high-performance catalyst, and isotacticity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] The preparation process of the solid catalyst component was the same as in Comparative Example 2, except that 2 g of acetyl tributyl citrate was added at the same time as 9,9-bismethoxymethylfluorene was added.

Embodiment 2

[0106] The preparation process of the solid catalyst component was the same as in Comparative Example 2, except that 3 g of acetyl tributyl citrate was added at the same time as 9,9-bismethoxymethylfluorene was added.

Embodiment 3

[0108] The preparation process of the solid catalyst component was the same as in Comparative Example 1, except that 1.5 g of acetyl tributyl citrate was added at the same time as 9,9-bismethoxymethylfluorene was added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com