Late transition metal catalyst for olefin polymerization and preparation method thereof

A post-transition metal and olefin polymerization technology, which is applied in the field of olefin polymerization catalysts and its preparation, can solve the problems of unsatisfactory effect and low number average molecular weight of polypropylene, so as to improve the number average molecular weight and isotacticity, and improve catalytic propylene polymerization active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Mix 0.1 mol of 2,6-diacetylpyridine, 0.1 mol of 4-aminophenol and 0.01 mol of methylbenzenesulfonic acid in toluene solvent and react at 60°C for 60 hours. Remove water from the resulting mixture, cool and filter , washed successively with dichloromethane, anhydrous ether and n-pentane, and then recrystallized with ethyl acetate to obtain 2,4,6-tribenzyloxybenzyl alcohol;

[0020] 2) 0.1 mol of methyl 2,4,6-tribenzyloxybenzoate and 0.009 mol of lithium aluminum hydride were reacted at 50°C for 3 hours under the protection of high-purity nitrogen, and the resulting mixture was sequentially injected into distilled water, 1 mol / L Aqueous sodium hydroxide solution and distilled water, left to precipitate and filtered, evaporated to obtain the preparation of 2,4,6-tribenzyloxybenzyl alcohol;

[0021] 3) 0.1mol of 2,4,6-tribenzyloxybenzyl alcohol, 0.055mol of carbon tetrabromide and 0.065mol of triphenylphosphine were reacted at 30°C for 0.3 hours under the protection of h...

Embodiment 2

[0025] 1) Mix 0.1 mol of 2,6-diacetylpyridine, 0.1 mol of 4-aminophenol and 0.15 mol of methylbenzenesulfonic acid in toluene solvent and react at 65°C for 65 hours. Remove water from the resulting mixture, cool and filter , washed successively with dichloromethane, anhydrous ether and n-pentane, and then recrystallized with ethyl acetate to obtain 2,4,6-tribenzyloxybenzyl alcohol;

[0026] 2), 3) with 2), 3) in embodiment 1;

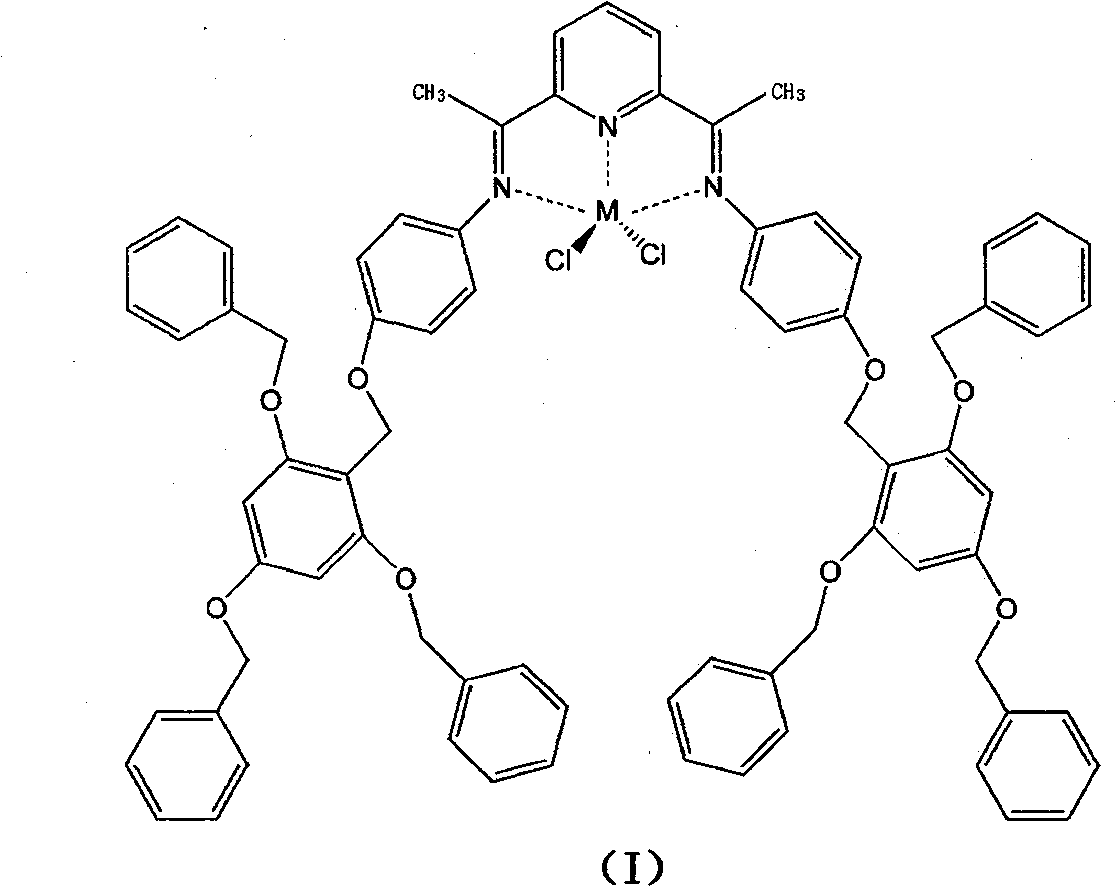

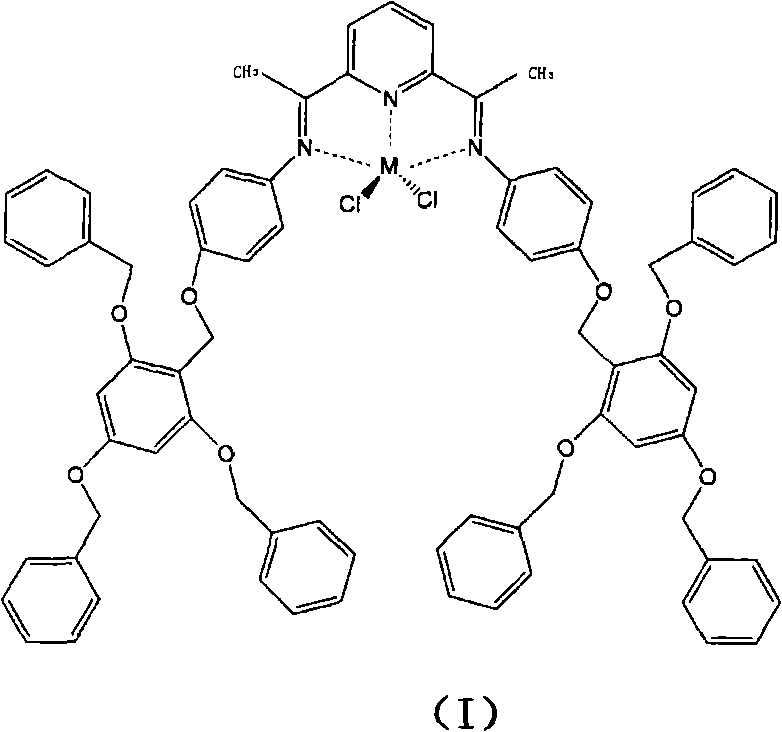

[0027] 4) 0.1 mol of the substance 2,4,6-tribenzyloxybenzyl bromide prepared by step 3), 0.04mol of the substance 2,4,6-tribenzyloxybenzyl alcohol prepared by step 1) and 1.2 mol potassium carbonate was reacted at 50°C for 68 hours under the protection of high-purity nitrogen, and the resulting mixture was cooled, filtered and evaporated to obtain the iron-based propylene polymerization catalyst ligand with wedge-shaped dendritic molecular structure involved in the present invention: 2,6- Bis[1-(4-(2,4,6-tris(benzyloxy)benzyloxy)phenylimine)ethyl]pyrid...

Embodiment 3

[0030] 1) Mix 0.1mol 2,6-diacetylpyridine, 0.1mol 4-aminophenol and 0.2 methylbenzenesulfonic acid in toluene solvent and react at 70°C for 75 hours. The resulting mixture is dehydrated, cooled and filtered, and used in turn Dichloromethane, anhydrous ether and n-pentane were washed continuously, and then recrystallized with ethyl acetate to obtain the substance 2,4,6-tribenzyloxybenzyl alcohol;

[0031] 2), 3) with 2), 3) in embodiment 1;

[0032] 4) 0.1 mol of the substance 2,4,6-tribenzyloxybenzyl bromide prepared by step 3), 0.045mol of the substance 2,4,6-tribenzyloxybenzyl alcohol prepared by step 1) and 1.3 mol potassium carbonate was reacted at 50°C for 68 hours under the protection of high-purity nitrogen, and the resulting mixture was cooled, filtered and evaporated to obtain the iron-based propylene polymerization catalyst ligand with wedge-shaped dendritic molecular structure involved in the present invention: 2,6- Bis[1-(4-(2,4,6-tris(benzyloxy)benzyloxy)phenylim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com