Device for producing biogas by two-phase three-section anaerobic digestion of high solids of perishable organic wastes

A technology for anaerobic digestion and organic waste, applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve the problem of reducing the efficiency of anaerobic digestion of perishable organic waste and the ability to produce biogas , reduce the concentration of raw materials and other issues, to achieve a good filtration effect, increase the concentration of treatment, and improve the effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

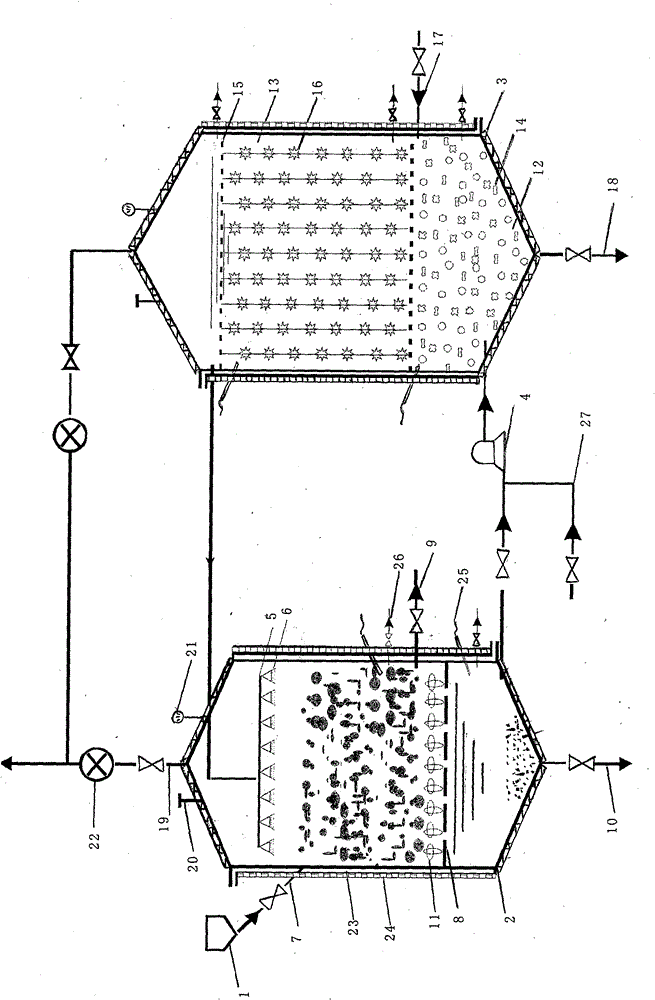

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] In the present embodiment, the device includes a feed hopper 1, a hydrolysis acid production reactor 2, and a methanation reactor 3; the bottom of the hydrolysis acid production reactor and the bottom of the methanation reactor are connected by a circulation pump 4 and a pipeline; the top of the methanation reactor and The top of the hydrolysis acid production reactor is connected by pipelines; the hydrolysis acid production reactor is a solid percolation bed reactor, and the top is provided with a water distributor 5 and a spray head 6; The discharge port 9 is provided with a slag discharge port 10 at the bottom, and the permeation packing 11 is placed on the porous plate 8; the methanogenic reactor is composed of a filter packing bed 12 and a fiber packing bed 13, the filter packing bed 12 is located at the bottom, and the fiber packing bed 13 is located The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com