Coating production line device for producing fruit-cultivation outer bag paper and production process method of fruit-cultivation outer bag paper

A production line and fruit growing technology, applied in papermaking, papermaking machines, paper recycling, etc., can solve the problems of increasing the difficulty and load of papermaking sewage treatment, loss of papermaking chemicals and pigments, and increasing the recycling of water in the middle section, so as to reduce sewage The effect of processing costs, reducing churn, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

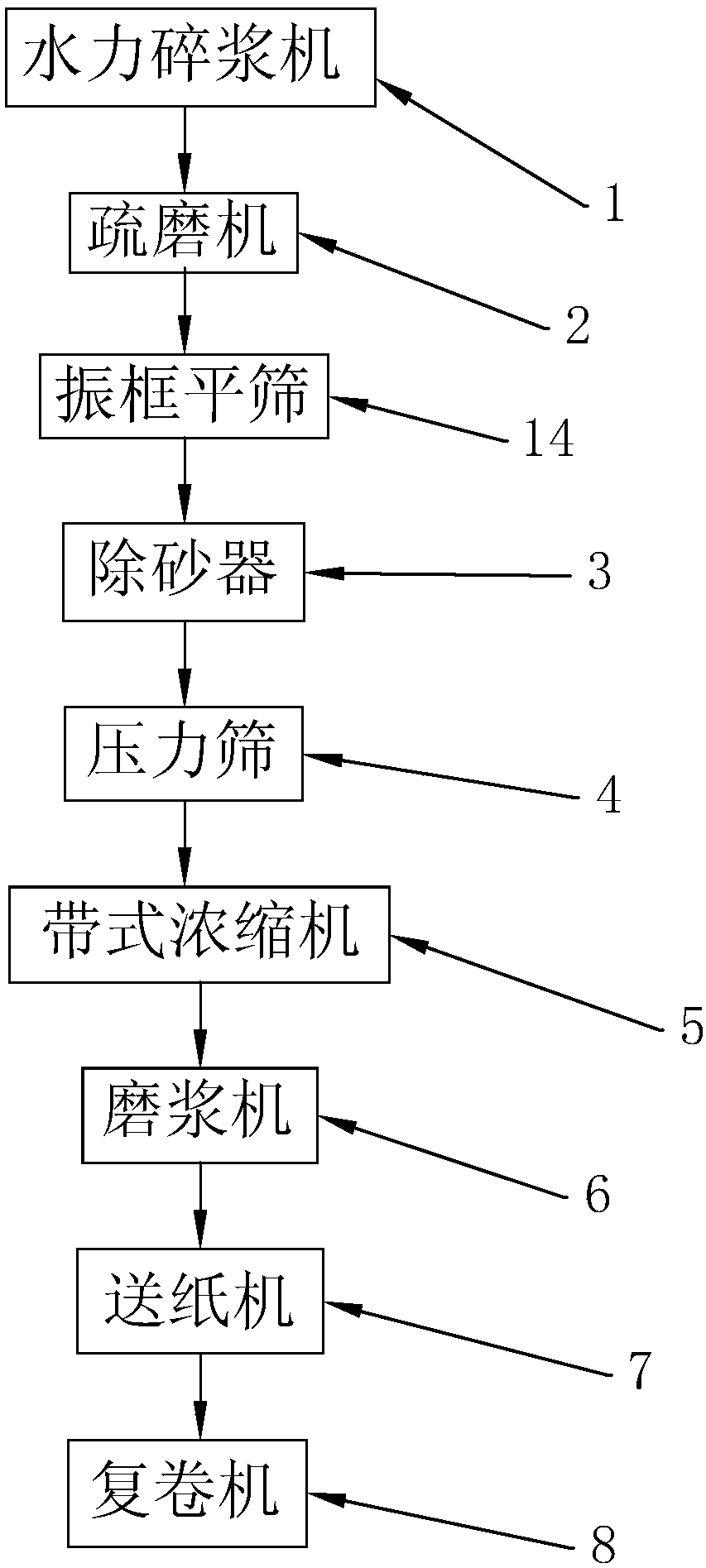

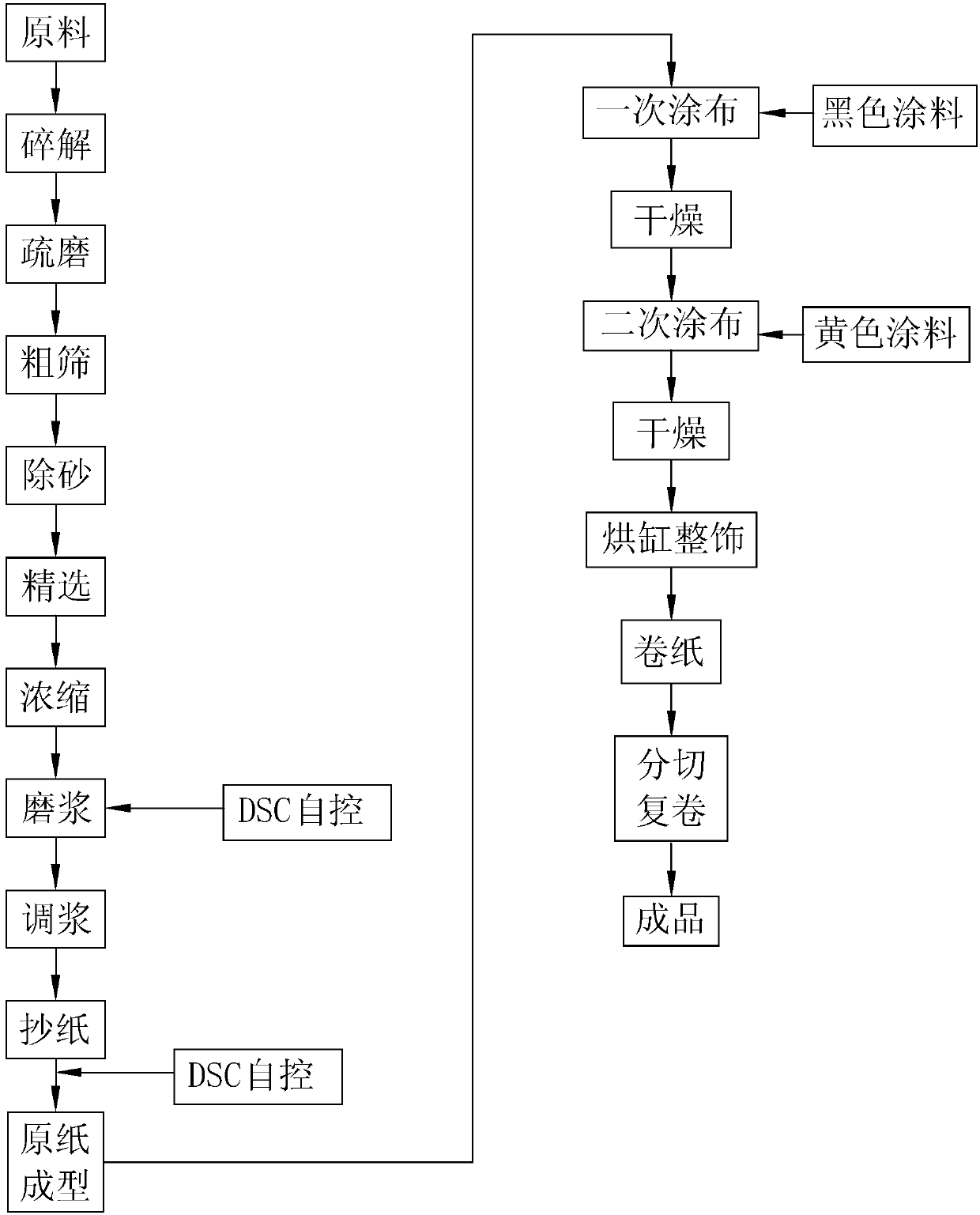

[0056] Reference Figure 1 to 2 As shown, the coating production line device for producing fruit-growing outer bag paper in this embodiment includes:

[0057] Hydraulic pulper for breaking up raw materials of pulp 1,

[0058] A thinner 2 used to grind the unbroken raw materials in the broken pulp,

[0059] Desander 3 for purifying and degreasing the pulverized pulp,

[0060] Pressure screen 4 used to select the pulp after de-sanding,

[0061] Belt thickener 5 for removing dirty water from the selected pulp,

[0062] A refiner 6 for refining concentrated and dewatered pulp,

[0063] A paper machine 7 used for papermaking operations on the refined pulp,

[0064] Rewinder 8 used for slitting the base paper produced after papermaking,

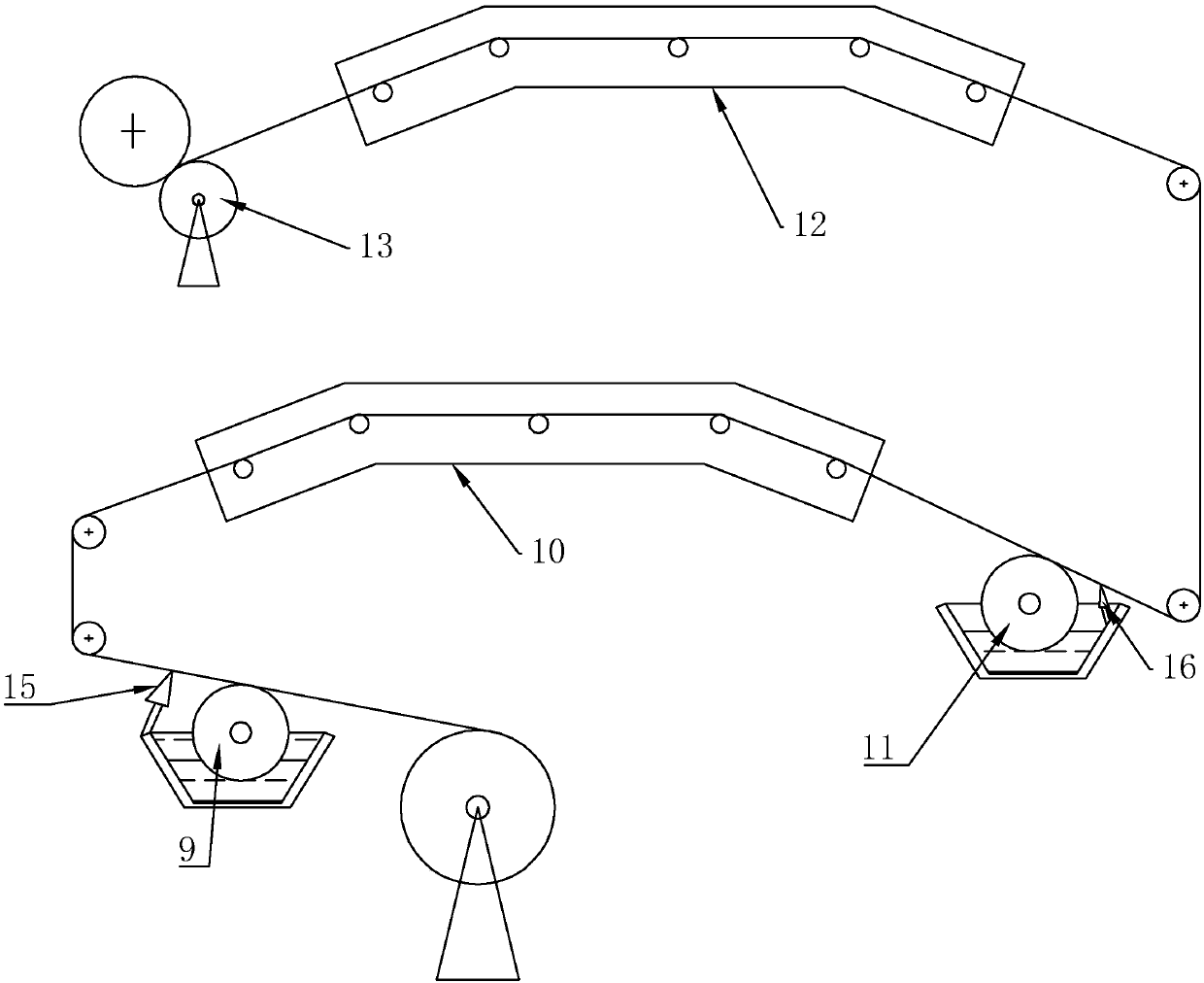

[0065] The first coating machine 9 used to perform the first coating operation on the cut base paper,

[0066] The first oven 10 for drying the base paper after the first coating operation,

[0067] The second coating machine 11 for the second coating operation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com