A method for cutting ultra-thin silicon wafers with ultra-thin steel wire

A technology of wire cutting and silicon wafers, which is applied in the direction of fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of low yield rate, affecting the cooling performance of cutting fluid, and increasing the risk of wire breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for cutting ultra-thin silicon wafers with ultra-thin steel wires, comprising the following steps: (1) slotting a main shaft, (2) sticking sticks, (3) configuring cooling liquid, (4) cutting, (5) blanking, ( 6) degumming and cleaning, (7) detection; the step (3) configures cooling fluid, the cooling fluid is pure water and water-based cutting fluid, and the concentration of the cutting fluid is 2.0%; the step (4) is used for cutting and cutting steel wire 60um diamond wire, diamond particles with a diameter of 6um, a spindle groove distance of 0.19mm, a cutting blade thickness of 115um, a groove angle of 24°, a groove depth of 0.28mm, and a main cutting speed of 1.3mm / min for bidirectional cutting. The groove bottom width is 55um. The line speed is 1600m / min.

[0018] When the tension is set to 5N, 6N, 7N, 8N, 9N, and 10N, the greater the tension, the higher the wire breakage rate, and the lower the tension, the lower the cutting efficiency. The best effect is...

Embodiment 2

[0023] A method for cutting ultra-thin silicon wafers with ultra-thin steel wires, comprising the following steps: (1) slotting a main shaft, (2) sticking sticks, (3) configuring cooling liquid, (4) cutting, (5) blanking, ( 6) degumming and cleaning, (7) detection; the step (3) configuration coolant, the coolant is pure water and water-based cutting fluid; the step (4) cutting, cutting steel wire uses 60um diamond wire, diamond particles use The diameter is 6um particles, the tension is 8N, the spindle groove distance is 0.19mm, the cutting blade thickness is 115um, the groove angle is 24°, the groove depth is 0.28mm, and the cutting speed of the main body is 1.3mm / min for bidirectional cutting. The groove bottom width is 55um. The line speed is 1600m / min.

[0024] The concentration of cutting fluid is 0.3%, 0.6%, 1%, 1.3%, 1.6%, and 2.0%, respectively. The concentration of 0.6% to 2.0% is better. Increase the cost and increase the viscosity of the cutting fluid, which is no...

Embodiment 3

[0029] A method for cutting ultra-thin silicon wafers with ultra-thin steel wires, comprising the following steps: (1) slotting a main shaft, (2) sticking sticks, (3) configuring cooling liquid, (4) cutting, (5) blanking, ( 6) degumming and cleaning, (7) detection; the step (3) configures cooling fluid, the cooling fluid is pure water and water-based cutting fluid; the step (4) cutting, 60um steel wire, diamond particles with a diameter of 6um Particles, the tension is 8N, the cutting fluid concentration is 2%, the spindle groove distance is 0.21mm, the cutting sheet thickness is 130um, the groove angle is 24°, the groove depth is 0.28mm, and the cutting speed of the main body is 1.3mm / min for bidirectional cutting. The groove bottom width is 55um. The line speed is 1600m / min.

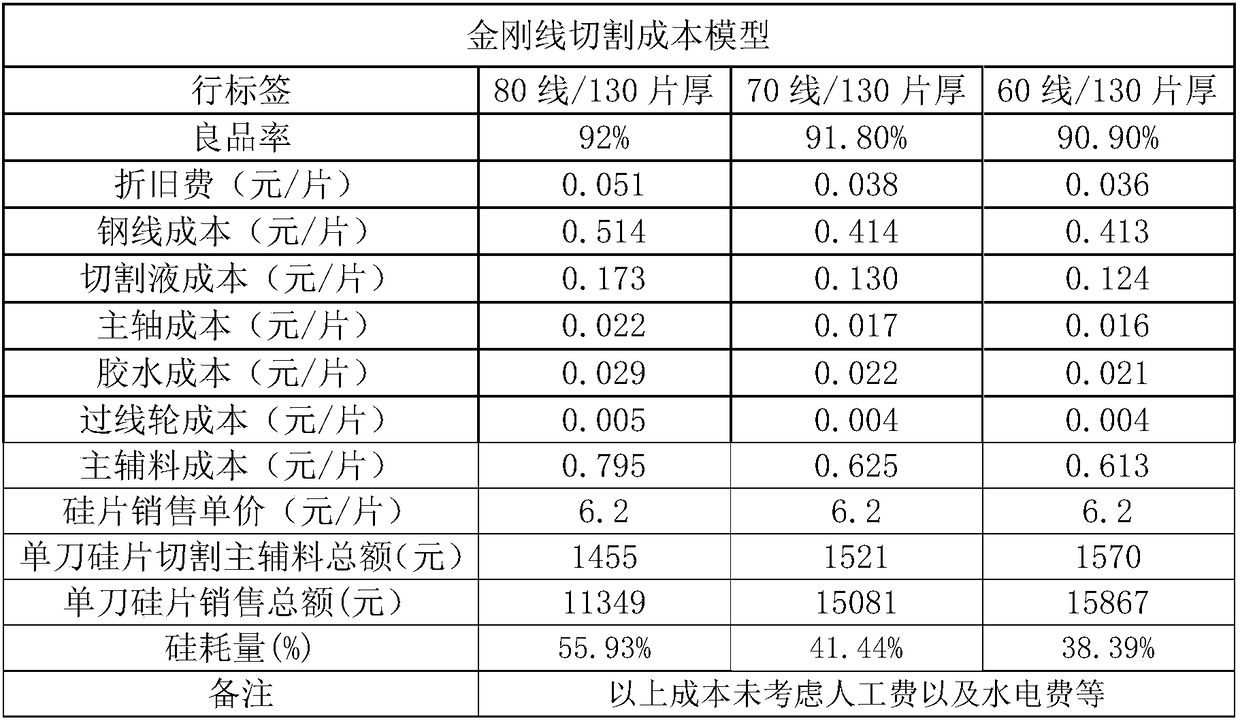

[0030] Comparing the use of 60um diamond wire with 70um and 80um diamond wire cutting, the 60um diamond wire has the lowest cutting cost, the highest income, the lowest silicon consumption, and the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com