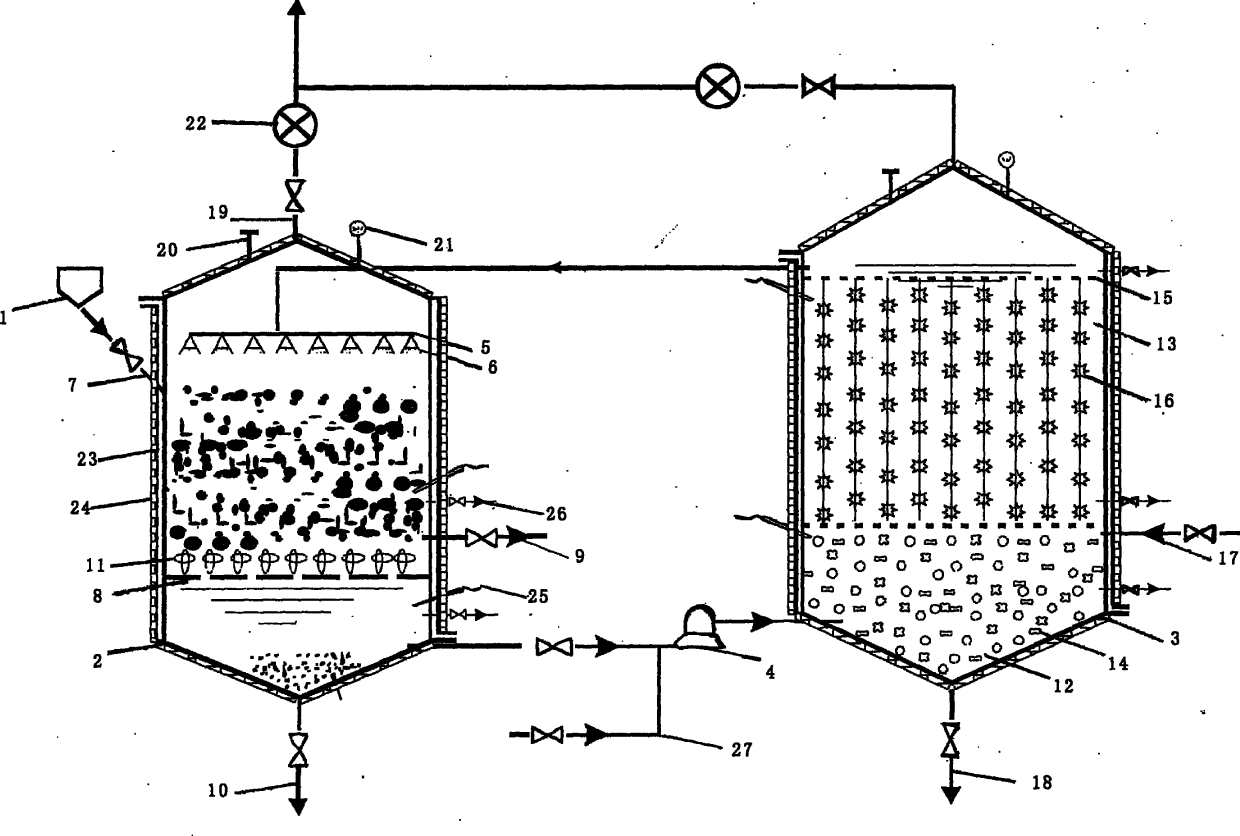

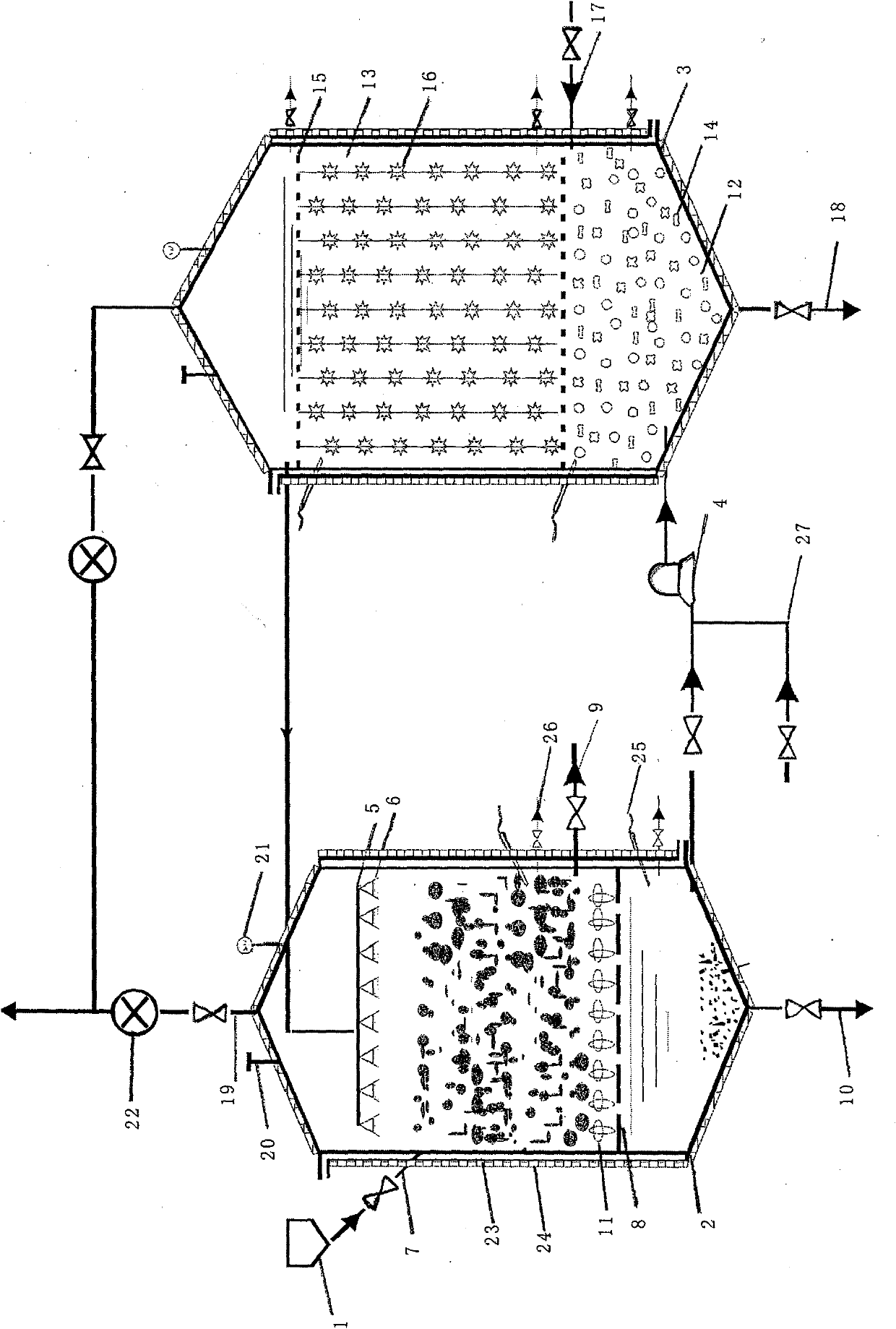

Method of producing biogas through high-solid two-phase three-stage anaerobic digestion by using perishable organic wastes

An anaerobic digestion technology for organic waste, applied in waste fuel, fermentation, etc., can solve the problems of reducing the anaerobic digestion treatment efficiency of perishable organic waste and biogas production capacity, reducing the concentration of raw materials, etc., to achieve good filtration effect, The effect of increasing the effective storage volume and increasing the effective processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add a small amount of kitchen waste from the feed hopper 1 to the hydrolysis acid production reactor 2, and control the temperature of the hydrolysis acid production reactor 2 at 37°C.

[0035] (2) Collect the anaerobic activated sludge in the digester, pump it into the methane reactor 3 through the branch pipeline 27, after the anaerobic activated sludge submerges the fiber filler 16, continue to pump the anaerobic activated sludge until it is hydrolyzed Kitchen waste leachate is formed at the bottom of the acid-generating reactor 2, and when the leachate height is close to the porous plate 8, the valve of the branch pipeline 27 is closed to stop pumping the anaerobic activated sludge. 37°C.

[0036] (3) In the hydrolysis acid production reactor in the above process, the kitchen waste is hydrolyzed in the anaerobic activated sludge to generate acetic acid, propionic acid, butyric acid, valeric acid, pyruvic acid, lactic acid, ethanol and a small amount of Carbon d...

Embodiment 2

[0044] The steps of this embodiment are the same as in Example 1, wherein the processing raw material is meat processing waste, and

[0045] In the step (2), the temperature of the control methanogenic reactor 3 is 25° C.; in the step (3), the hydrolysis acid production control pH is 6.5; 8.0; in the step (5), through 20 days of repeated leachate circulation, the temperature of the control hydrolysis acid production reactor 2 is 25 ℃, and the pH is 6.5; the temperature of the methanogenic reactor is 25 ℃, and the pH is 8.0; the step In (6), the temperature of the hydrolysis acid production reactor is controlled to be 25°C, the pH is 6.5, the temperature of the methane production reactor is 25°C, and the pH is 8.0; in step (7), part of the meat processing waste is removed every 40 days for hydrolysis residue; every 60 days in step (8), remove the leachate sediment; every 60 days, clean and refill the filter filler 14 in the filter bed 12 .

Embodiment 3

[0047] The steps of this embodiment are the same as in embodiment 1, wherein the processing raw material is vegetable processing waste, and

[0048] In the step (1), the temperature of the hydrolysis acid generation reactor 2 is controlled to be 60° C.; the temperature of the methane production reactor 3 is controlled to be 60° C. in the step (2); the hydrolysis acid generation control temperature of the step (3) is 60° C. The pH is 4.5; in the step (4), the control temperature of acetic acid and methane production is 60 ℃, and the pH is 6.5; in the step (5), the temperature of the hydrolysis acid production reactor 2 is controlled through multiple leachate circulations of 15 days. 60 DEG C, the pH is 4.5; the temperature of the methanogenic reactor 3 is 60 DEG C, and the pH is 6.5; the temperature of the controlled hydrolysis acid production reactor 2 in step (6) is 60 DEG C, and the pH is 4.5; The temperature is 60°C and the pH is 6.5; in step (7), remove part of the vegetab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com