Device and method for detecting pavement evenness based on image moire method

A detection device and flatness technology are applied in the field of road surface flatness detection methods, which can solve the problems of low test accuracy, low detection accuracy, slow test speed, etc., and achieve good interference fringe contrast, high measurement efficiency, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

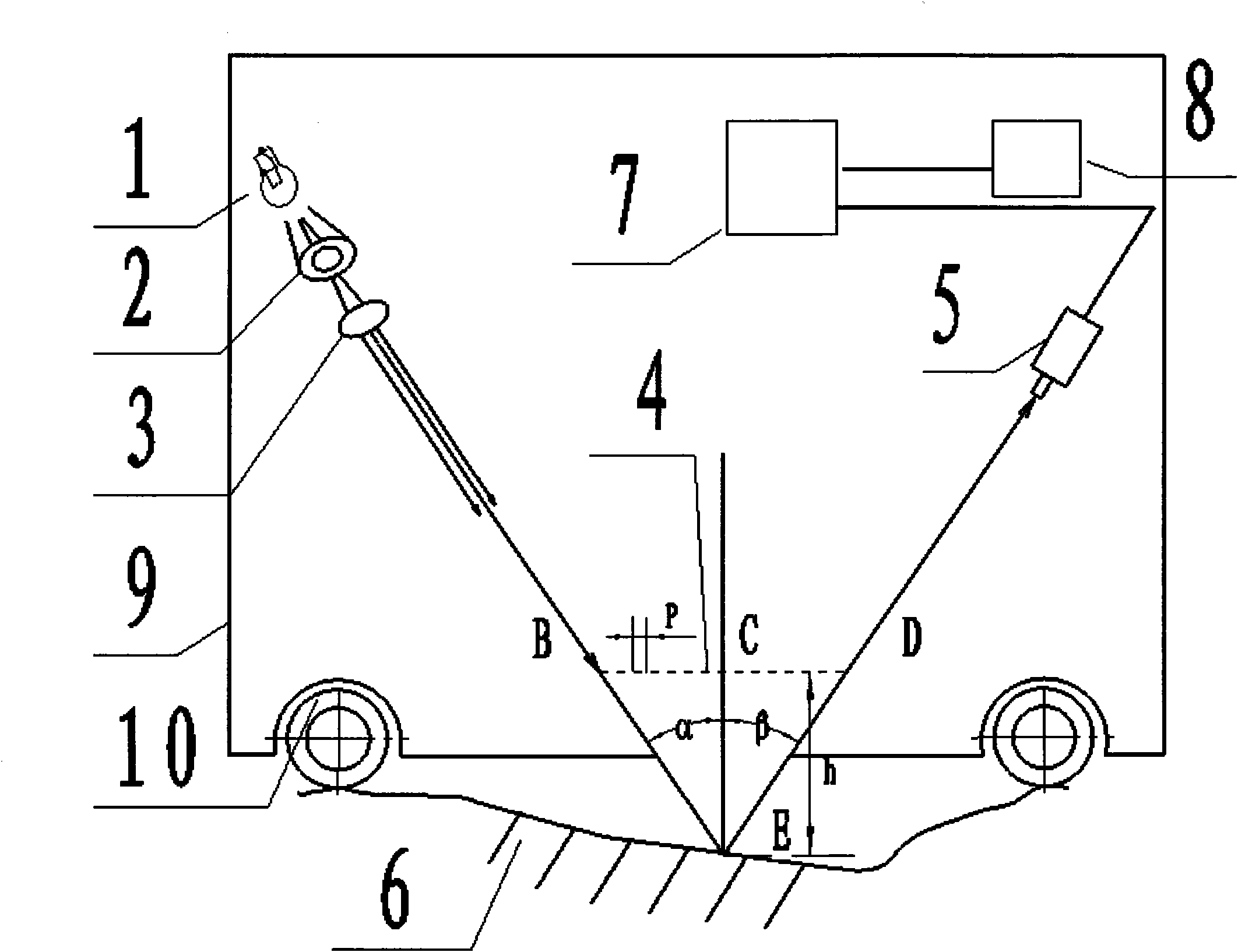

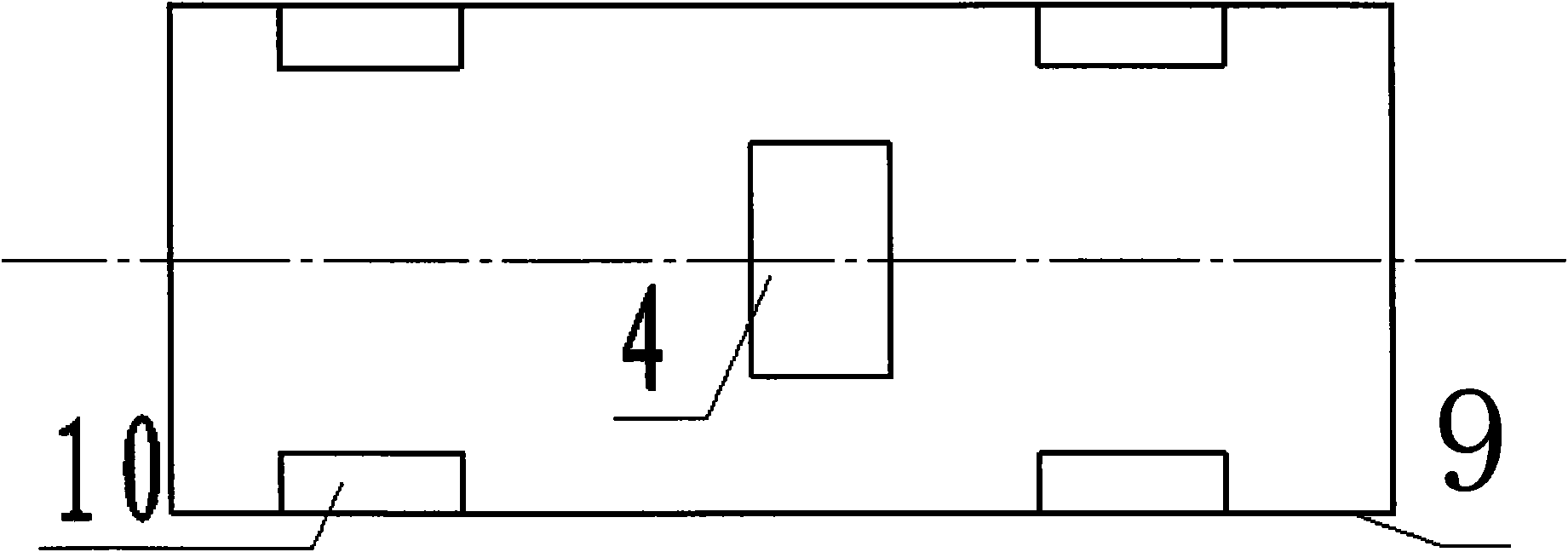

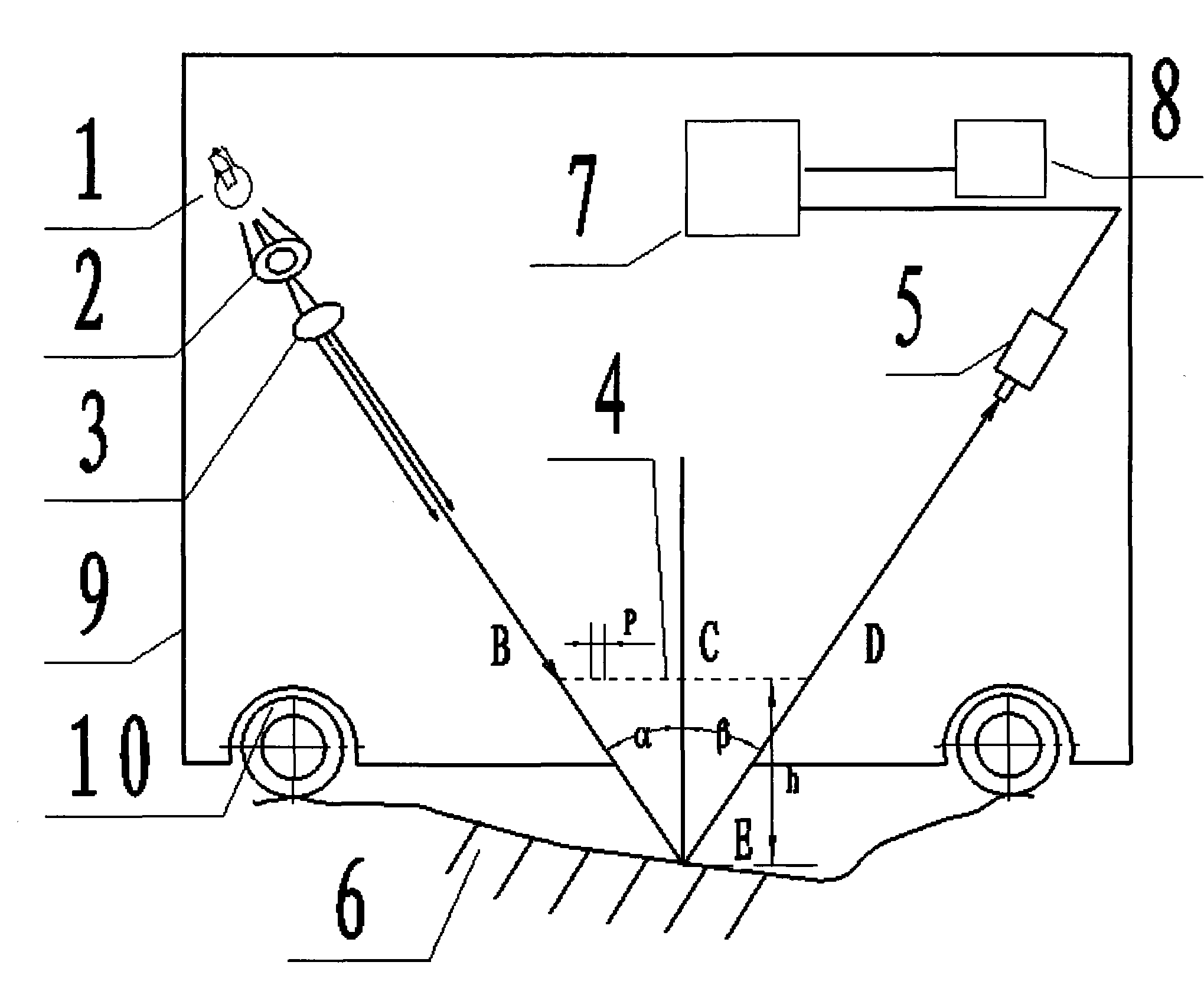

[0020] Embodiment 1, a road surface roughness detection device based on the image moiré method, wherein: it consists of a car body 9, a wheel 10, a reference grid 4 arranged on the inner floor of the vehicle, a light source 1 located on one side of the reference grid 4, a filter device 2, focusing lens 3, CCD camera 5 on the other side, road surface 6 below the reference grid 4, terminal processing device 7 and printout device 8; light source 1, filter 2, and focusing lens 3 are linear Arranged, the light strip emitted by the light source 1 can cover the longitudinal road surface 6, the light emitted by the light source 1 forms an angle α with the normal line of the reference grid 4, and the incident light entering the CCD camera 5 forms an angle β with the grating 4; the CCD camera 5 can obtain the road surface 6 moiré image information; the terminal processing device 7 is connected with the CCD camera 5.

Embodiment 2

[0021] Embodiment 2, the detailed implementation steps of the road surface roughness detection method based on the image moiré method are as follows:

[0022] Firstly, the car body 9 is pulled forward by the tractor, and the light strips emitted by the laser light source 1 pass through the spatial filter 2 to form a light field with a large area, and then become parallel light after passing through the focusing lens 3, and pass through the reference grating 4 The formed image is projected onto the road surface 6, and the image and the reference grid 4 interfere with each other to form an interference moiré image. The CCD camera 5 captures and saves the interference moiré image and transmits it to the terminal processing device 7, and can perform real-time dynamic adjustment with reference to the image aggregation effect on the screen of the terminal processing device 7.

[0023] Secondly, the moiré image is filtered by the image processing software in the terminal processing d...

Embodiment 3

[0044]Embodiment 3, a road surface roughness detection device based on the image moiré method, comprising a light source 1, a filter 2, a focusing lens 3, a reference grid 4, a CCD camera 5, a terminal processing device 7, a car body 9 and wheels 10; wherein: The bottom plate in the vehicle body 9 is provided with a reference grid 4, the light source 1, the filter 2, and the focusing lens 3 are all located on one side of the reference grid 4, the CCD camera 5 is located on the other side of the reference grid 4, and the road surface 6 is located on the side of the reference grid 4. Below, the vehicle body 9 and the wheels 10 are connected and arranged on the road surface 6 ; the terminal processing device 7 is connected with the CCD camera 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com