Vortex fluid machinery

A fluid machinery and scroll technology, which is applied to rotary piston machinery, mechanical equipment, liquid fuel engines, etc., can solve the problems of no disclosure of capacity control and simultaneous back pressure control, no description of back pressure control, etc. Simple structure, secure sealing, and the effect of suppressing sliding friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

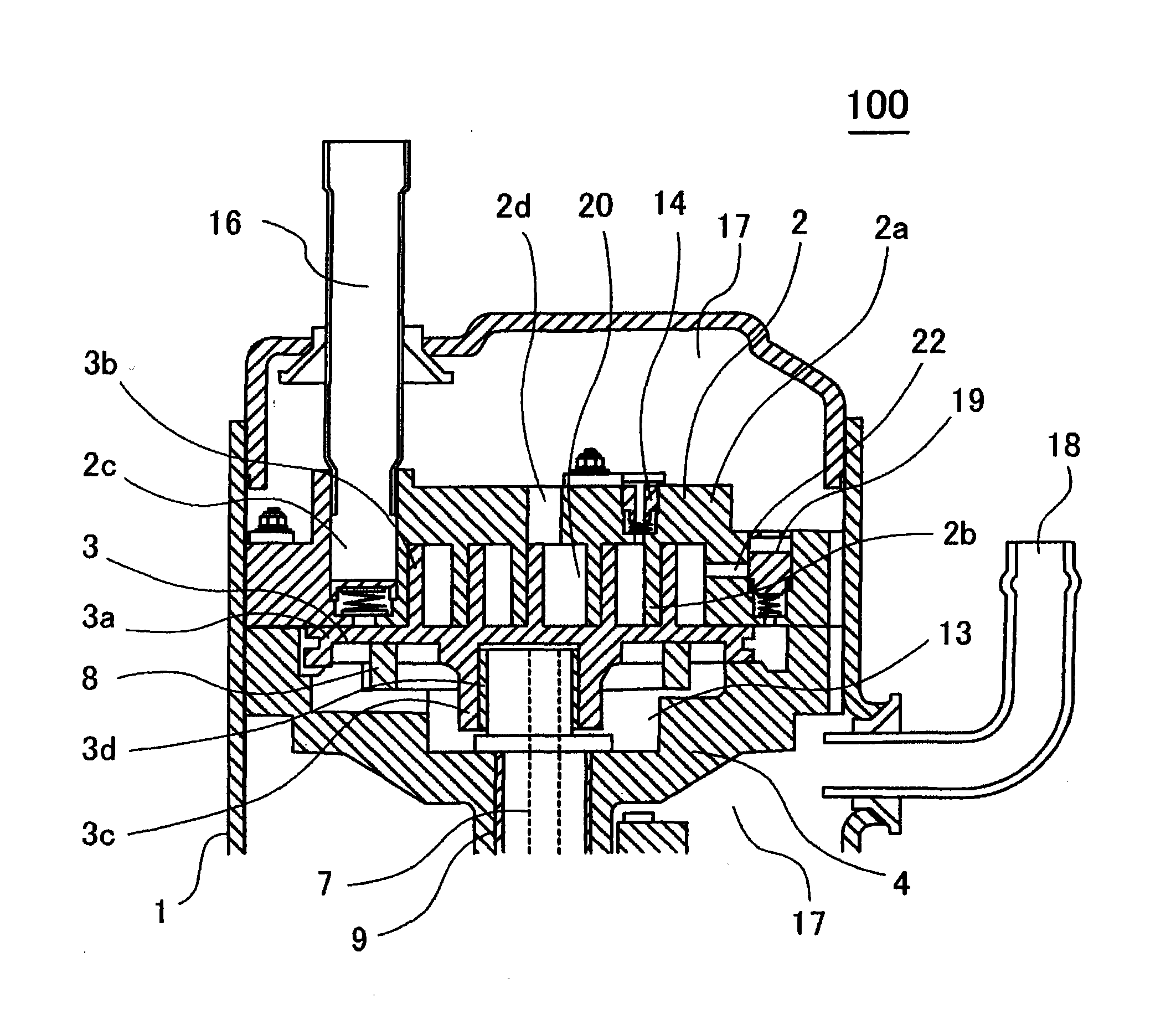

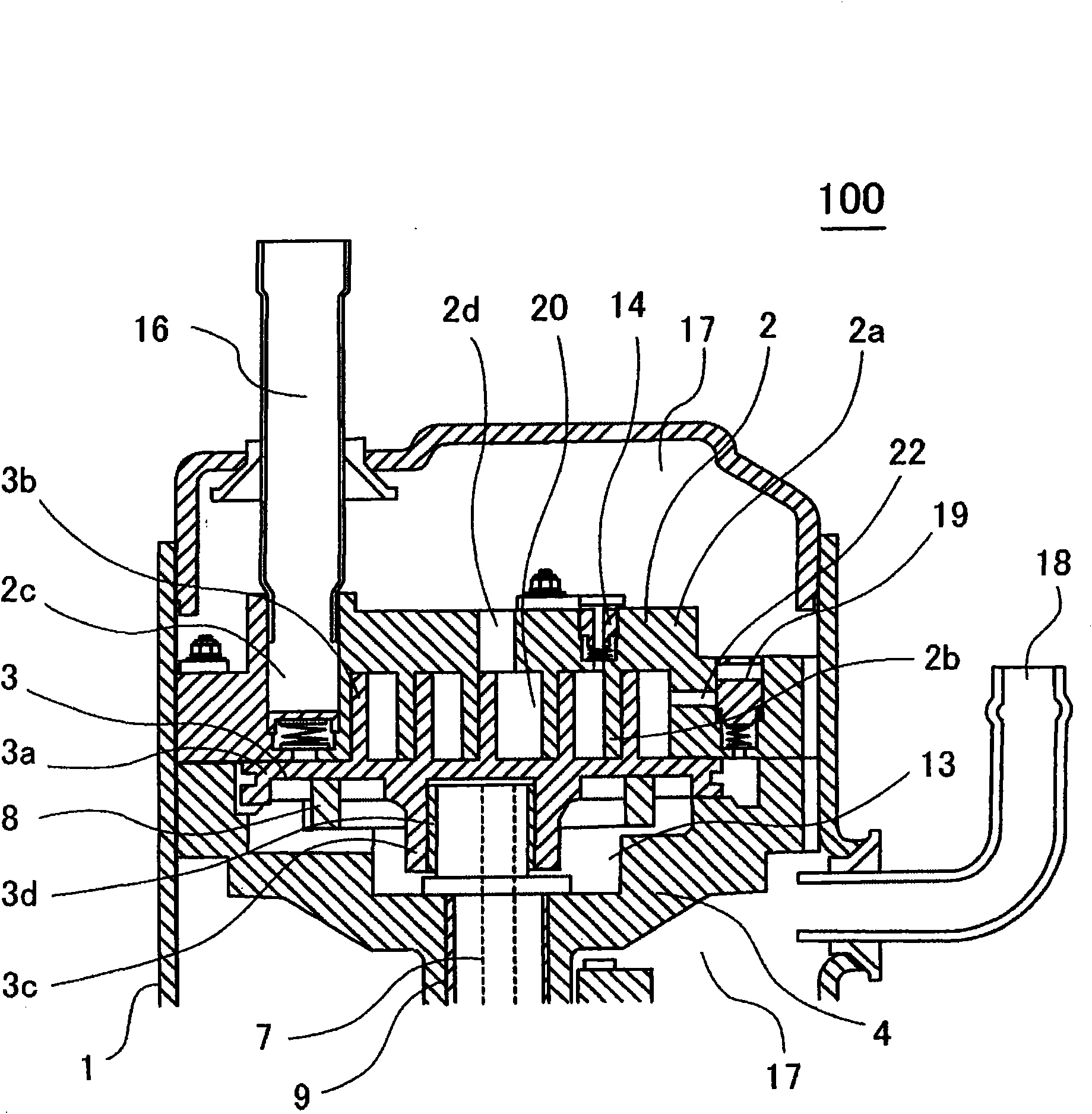

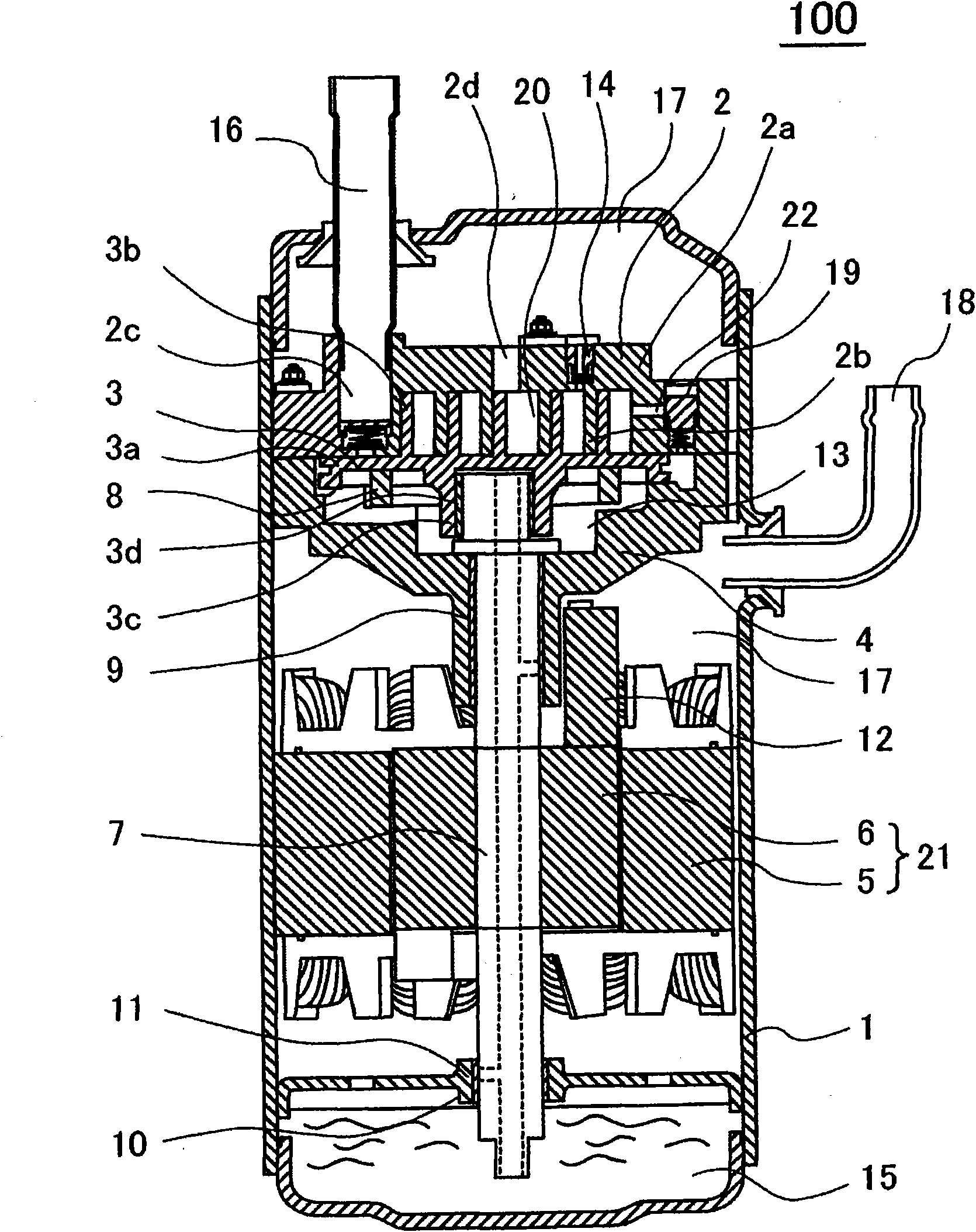

[0079] A scroll compressor 100 according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 4 . First, the scroll compressor 100 will be described with reference to FIGS. 1 and 2 . Fig. 1 is a sectional view of a compression mechanism of a scroll compressor according to a first embodiment of the present invention. Fig. 2 is a sectional view of the entire scroll compressor.

[0080] The scroll compressor 100 has a structure in which a compression mechanism performing a compression operation and a drive mechanism including an electric motor are housed in a closed casing 1 .

[0081] The compression mechanism includes the following basic elements: a non-revolving scroll 2 , a revolving scroll 3 , and a frame 4 . Compression chamber 20 is formed by meshing non-orbiting scroll 2 and orbiting scroll 3 .

[0082] The non-orbiting scroll 2 includes the following basic components: an end plate 2a; and a scroll-shaped wrap 2b erected on the ...

no. 2 approach

[0105] A second embodiment of the present invention will be described using FIGS. 5 and 6 . 5 and 6 are structures in which the capacity control mechanism and the back pressure control mechanism are separated. In FIGS. 5 and 6 , although the back pressure control mechanism is not shown, the back pressure control mechanism having the function of adjusting the back pressure as described in the first embodiment is provided. Alternatively, a back pressure control mechanism is provided in which the needle valve 19c of the back pressure control mechanism 19 is fixed by pressing etc., the spring length of the back pressure control spring 19b is made constant, and the full operation without capacity control is provided. Under the condition that the sealing performance of the compression chamber 20 is sufficiently ensured, it is set as (back pressure)=(suction pressure)+(constant value). Alternatively, a back pressure control mechanism that does not use the valve described in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com