Device for measuring secondary suspension parameters of railway vehicle bogie based on simulated frame

A technology for secondary suspension and parameter measurement, which is used in measuring devices, railway vehicle testing, torque measurement, etc. It can solve the problems of complex structure, high requirements for parts processing and assembly accuracy, and high equipment manufacturing and maintenance costs. Reliable and stable work, cost reduction effect

Inactive Publication Date: 2010-08-25

JILIN UNIV

View PDF6 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the four-column structure mentioned in this patent has a complex structure, high precision requirements for parts processing and assembly, and high equipment manufacturing and maintenance costs.

At the same time, the test system can only test the bogie product alone, and cannot test the bogie with the car body

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

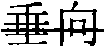

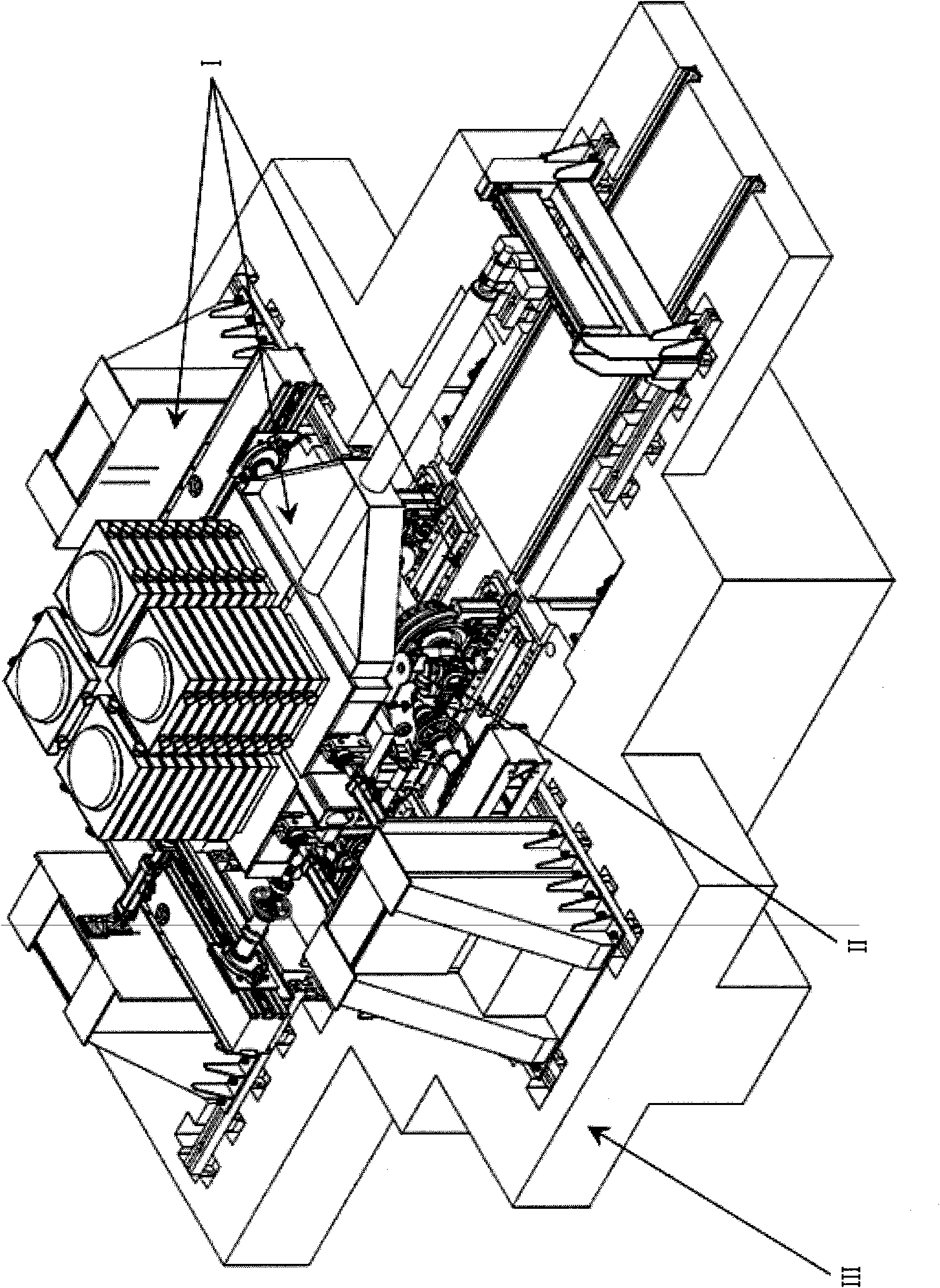

The invention relates to a device for measuring secondary suspension parameters of a railway vehicle bogie based on a simulated frame. The device comprises a plurality of weights (h), the simulated frame (i) for test, a set of moving flame (j) for supporting the simulated frame for test, two secondary three-dimensional force platforms (k), a longitudinal actuator (1) of the simulated frame, two transverse actuators (m) of the simulated frame, two vertical actuators (n) of the simulated frame and four sets of vertical pull-down pin sensors and connecting rods (o), wherein the weights (h) are mounted on the simulated frame (i); the secondary three-dimensional force platforms (k) are respectively connected with the simulated frame (i) and a railway vehicle bogie to be measured (II); a spindle (7) for supporting the simulated frame is supported by the moving flame (j) for supporting the simulated frame; and one ends of the transverse actuators of the simulated frame are respectively hinged with framework locating supports and the other ends thereof are connected with the simulated frame. The device can be used for dynamic and static measurement of secondary comprehensive parameters of various railway vehicle bogies.

Description

technical field The invention relates to comprehensive parameter testing equipment for a rail vehicle bogie, in particular to a bogie characteristic parameter detection platform for measuring the comprehensive parameters of the secondary suspension of the bogie based on a simulated car body. Background technique A typical railway vehicle bogie is mainly composed of a frame, two-series suspension, wheelset, etc., on which the vehicle body is carried, and it is the running mechanism of the rail vehicle. The main parameters of the rail vehicle bogie include the vertical stiffness, longitudinal stiffness, transverse stiffness, slewing stiffness, anti-diamond stiffness and slewing friction moment of the primary and secondary series. The size and matching of each parameter determine the bogie dynamics. Performance is good or bad, in line operation, these parameters directly affect the speed, stability, comfort and safety reliability of the train. Therefore, it is very necessary t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M17/08G01M5/00G01L3/00

Inventor 苏建张栋林蓝志坤罗士军陈熔刘玉梅潘洪达张立斌戴建国林慧英徐观宫海彬

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com