Method for improving coupling luminous efficiency of flat plate luminescent device

A technology for light-emitting devices and light extraction efficiency, which is applied in the manufacture of electrical solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., and can solve problems such as complicated micro-lens technology, difficult control of micro-lens size, and poor mechanical properties of micro-lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

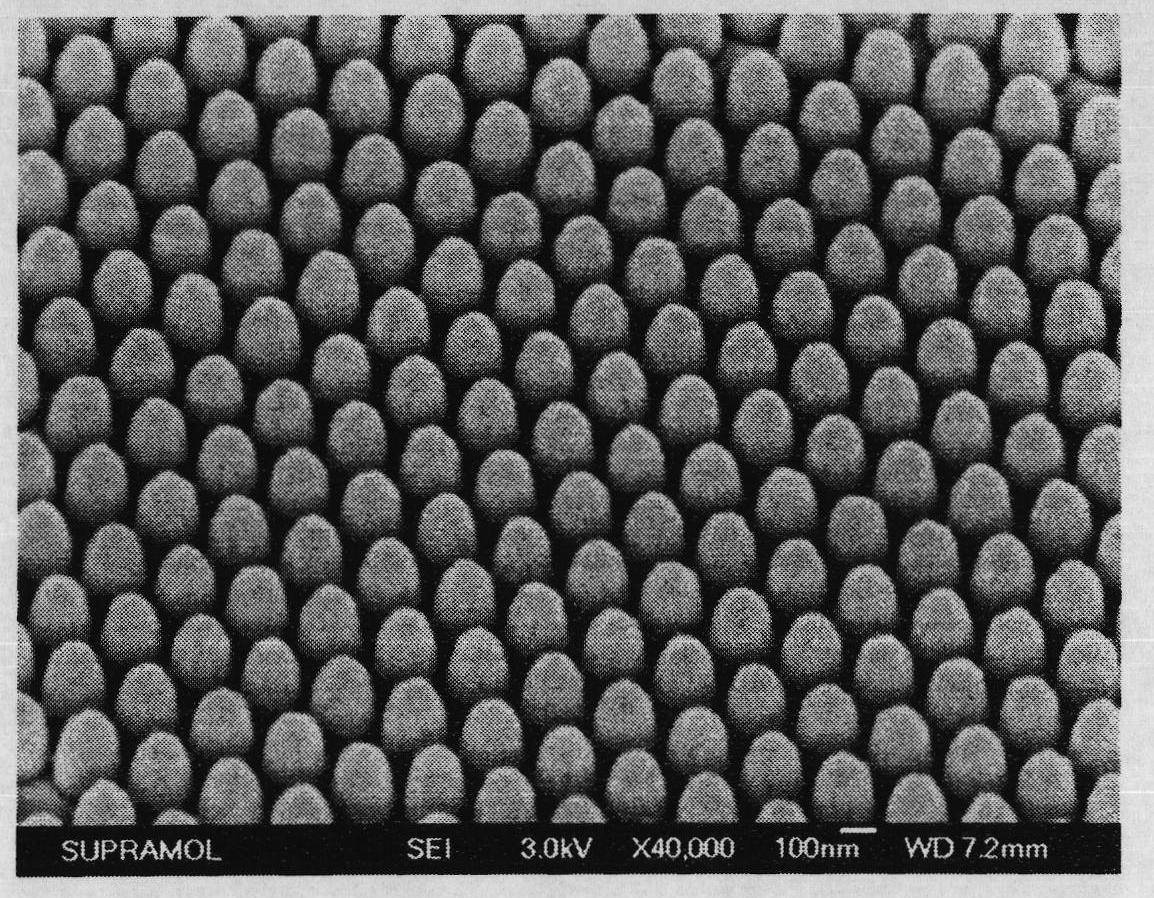

[0028] 1. The preparation method of polystyrene microspheres:

[0029] Under nitrogen protection, with 40 milliliters of absolute ethanol and 100 milliliters of deionized water as the dispersion medium, 3.3 milliliters of styrene, 0.0733 grams of potassium persulfate, and 0.0807 grams of sodium dodecylsulfonate were added to the In the reactor of the mechanical stirrer and the reflux condenser, the mechanical stirring speed was 350 rpm. The polymerization reaction was carried out in a water bath at 70° C., and after 10 hours of reaction, a stable milky white emulsion of monodisperse polystyrene microspheres was obtained, and the diameter of the microspheres was 204 nanometers.

[0030] 2. Preparation of tightly packed monolayer polystyrene microspheres:

[0031]The prepared polystyrene microspheres were centrifuged and washed, and then dispersed with a mixed solution of absolute ethanol and deionized water with a volume ratio of 1.5:1 to obtain a monodisperse polystyrene micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com