Method for improving efficiency of outing light coupled from tabulate light emitting device

A technology of light-emitting devices and light extraction efficiency, which is applied in the manufacture of semiconductor devices, electric solid-state devices, semiconductor/solid-state devices, etc. It can solve the problems of difficult control of the size of micro-lenses and achieve the effect of consistent size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

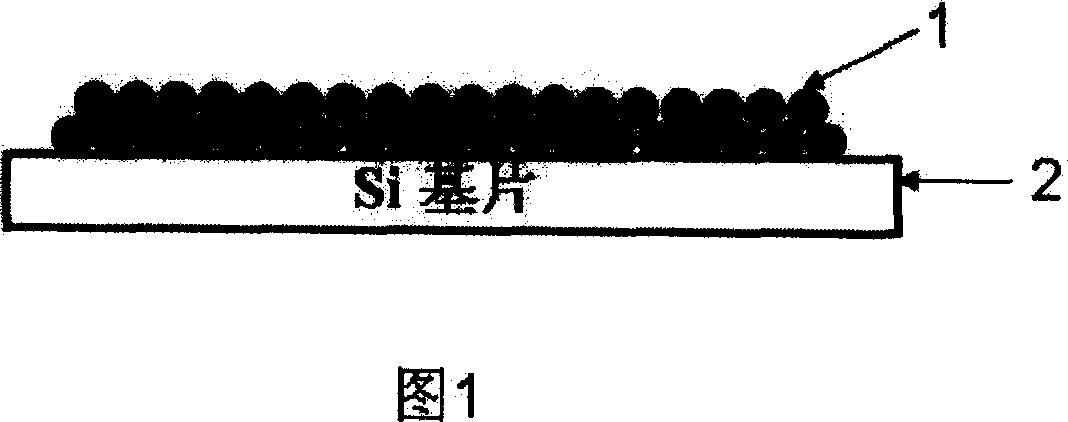

Embodiment 1

[0037] Monodisperse silica microspheres of various diameters were prepared in ethanol. For narrowly dispersed silica microspheres with a diameter below 500nm, the following method is used: 14ml tetraethyl orthosilicate is dissolved in 100ml ethanol, 27.5ml water, 9.5ml ammonia water are dissolved in 100ml ethanol, and then the two solutions are mixed and stirred at room temperature 6 hours. The emulsion was then centrifuged and washed three times with ethanol or water, and finally dried in an oven at 60°C. For silica microspheres with a diameter of 500nm to 1.4μm, the operation is similar to the above, only need to introduce a seed silica powder or emulsion with a size of 250nm to 500nm in the system (if it is a powder, it needs to be completely dispersed by ultrasonic before use. ). After the reaction is completed, wash and dry in the same way.

[0038] The microspheres with different diameters are classified by a centrifuge, and the silica microspheres with a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com