Adhesive tape application device and tape connection method

An adhesive tape and attachment technology, applied in the directions of adhesive, transportation and packaging, application, etc., can solve the problems of increased burden, difficulty in ensuring connection strength, and inability to automatically connect, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

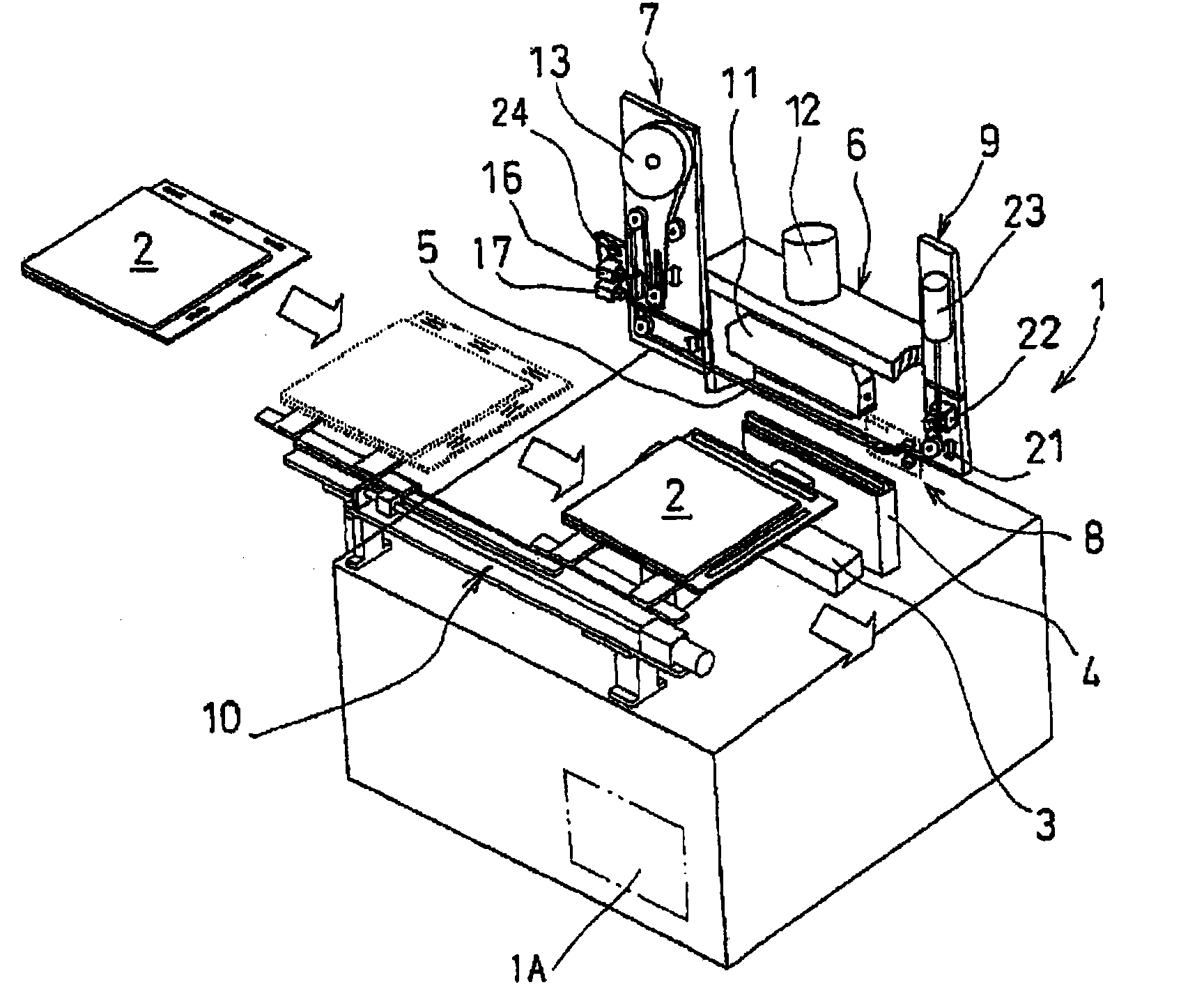

[0073] First, an ACF applying device as an example of the adhesive tape applying device according to the first embodiment of the present invention will be described with reference to FIGS. 1 , 2 , 3 , 4A, 4B, and 4C.

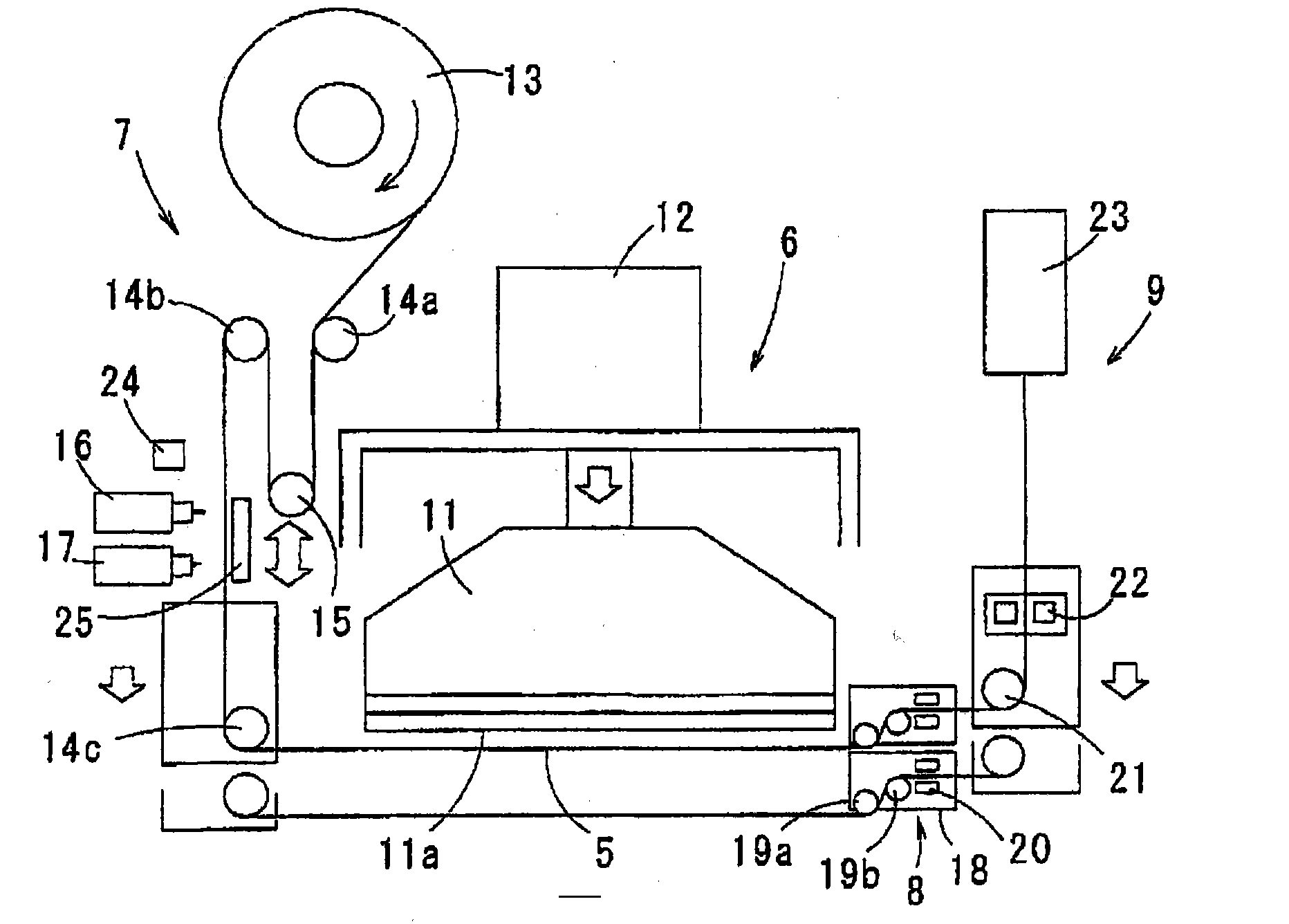

[0074] In Fig. 1 and Fig. 2, the ACF attaching device 1 of the present embodiment includes: a positioning device 3 for supporting the substrate 2 to move and position it; a lower support table 4 for supporting the side end of the substrate 2 from below; A crimping device 6 that presses the ACF tape 5 to be attached to the substrate 2; a tape supply device 7 that supplies the ACF tape 5; Tape peeling device 8; tape recovery device 9 for recovering the release tape of the peeled ACF tape 5. 10 is a transfer device for transferring the substrate 2 sent to the feeding position of the ACF attaching device 1 to the positioning device 3 . In FIG. 1 , 1A is a control device that controls the overall operation of the ACF sticking device 1 .

[0075] As shown in FIG. 2,...

no. 2 approach

[0090] Next, an adhesive tape sticking device according to a second embodiment of the present invention will be described with reference to FIGS. 5 to 13 . In addition, the same reference numerals are assigned to the same constituent elements as those of the above-mentioned first embodiment, description thereof will be omitted, and differences will be mainly described.

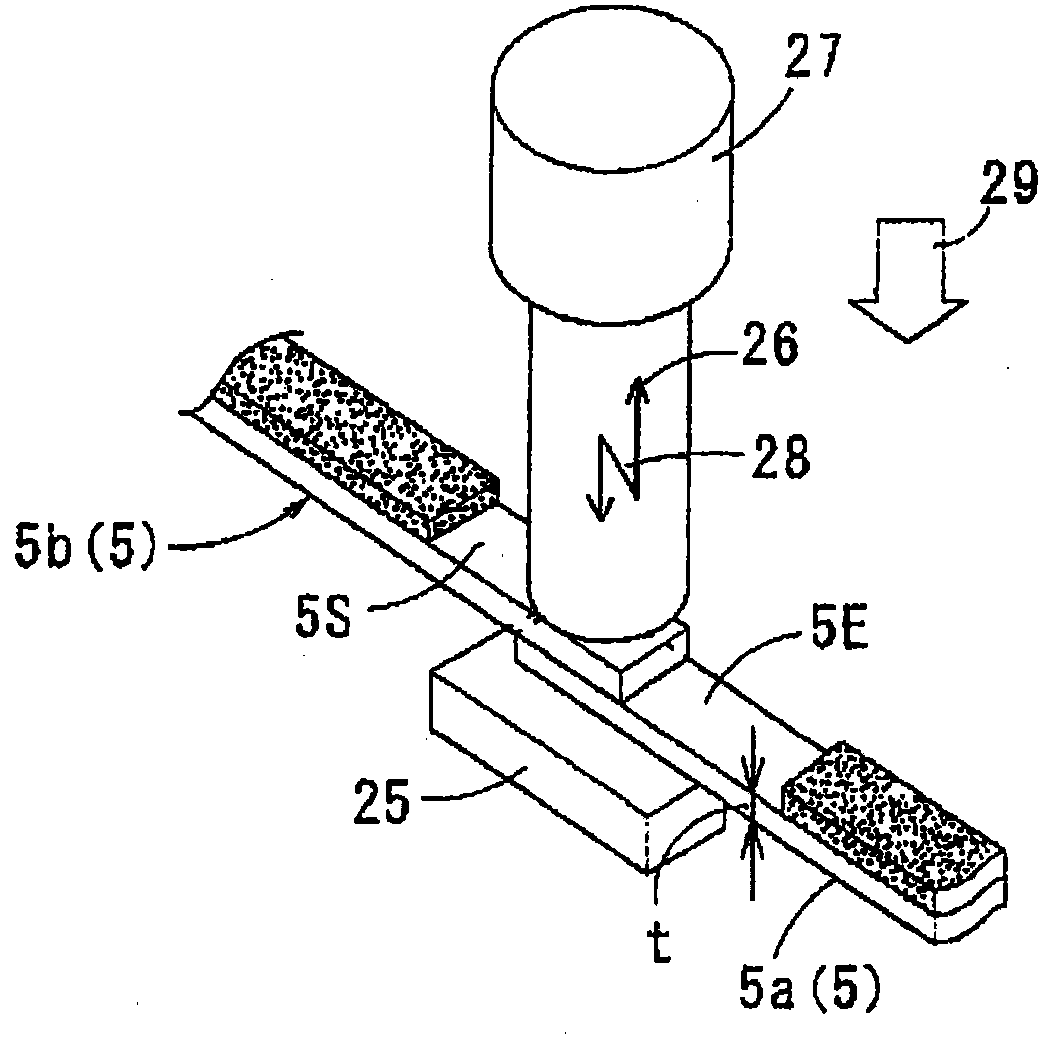

[0091] This embodiment is mainly different from the first embodiment in the structure of the tape supply device 7 and the tape recovery device 9, which can automatically connect the end portion 5E of the first ACF tape 5a and the start end portion 5S of the second ACF tape 5b, thereby continuously The ACF belt 5 is supplied ground.

[0092] In FIG. 5 , the tape supply device 7 is provided with a tape connecting device 31 for connecting the end portion 5E of the first ACF tape 5a and the start end portion 5S of the second ACF tape 5b, and a reel supply device 32 for sequentially supplying the reels 13. The tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com