Pressure soymilk grinder

A soymilk maker and pressure technology, which is applied in home appliances, applications, kitchen utensils, etc., can solve the problems of not meeting the nutritional requirements, poor taste of cooking milk, inconvenient cleaning, etc., to prevent the loss of food nutrients and reduce processing costs , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

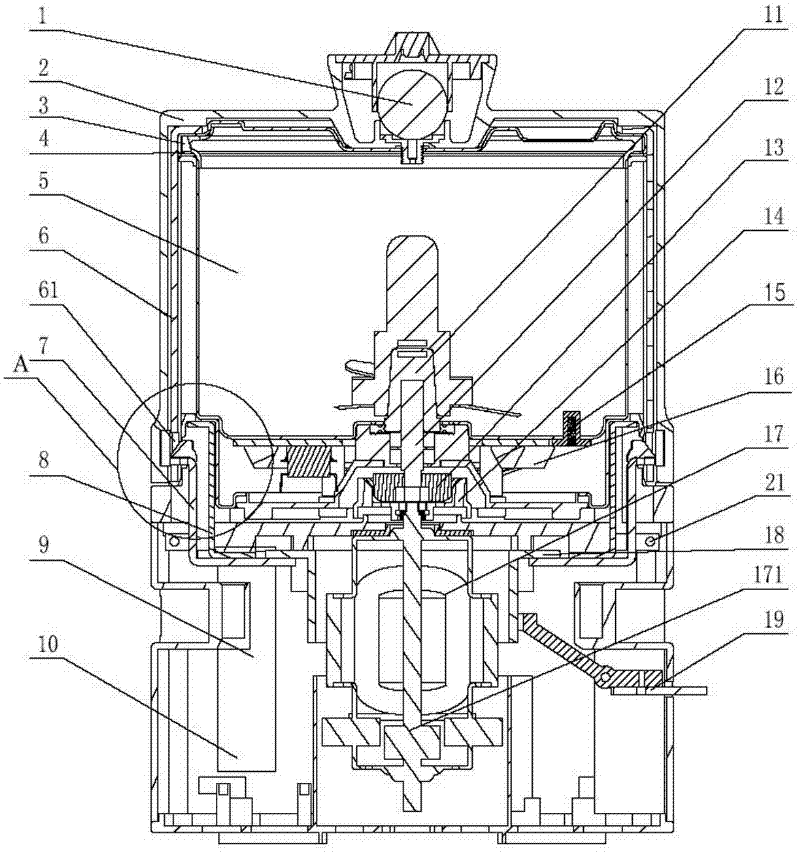

[0039] like Figure 1-Figure 6 As shown, this pressure soybean milk machine is a pressure soybean milk machine with a motor under it.

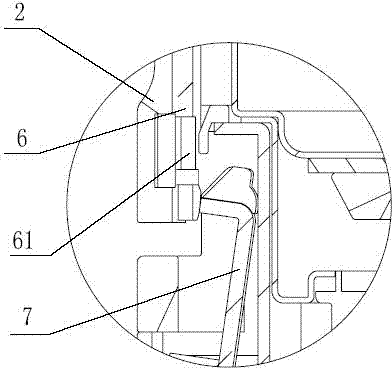

[0040] It includes a cup body 5 for pulping, a heating element, a temperature detection device, a machine base, an outer cover (2) or / and an inner cover 4, the inner cover and the mouth of the cup body are provided with an elastic sealing ring 3, and the outer cover is provided with There is a pressure relief device, a driving motor and a control circuit board 10 that provide power are provided in the machine base, the driving blade 11 is placed in the cup body, the cutter shaft 12 and the motor shaft 171 are connected through the clutch A 13 and the clutch B 14, and the upper part of the machine base is placed There is a metal sheet or a metal inner cover supporting the cup body, and the cup body is placed above the metal sheet 8,

[0041] like figure 1 As shown, the motor 17 is placed in the base 9, the motor shaft 171 passes through the b...

Embodiment 2

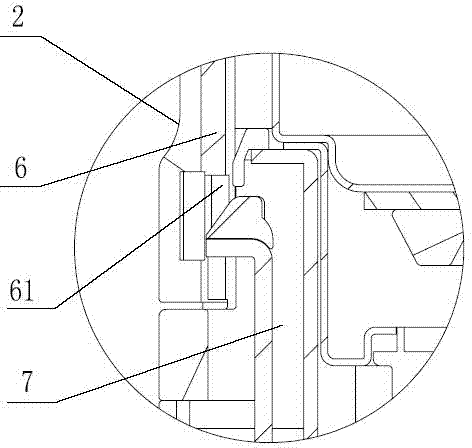

[0051] like Figure 7-Figure 12 As shown, this pressure soymilk machine is an embodiment with a motor under it, and its implementation form is basically the same as that of Embodiment 1. The hole on the side of the cover 4 is used as a guide buckle groove 61 to realize the direct buckling of the inner cover 4 and the buckle hook 7 .

[0052] like Figure 7 As shown, the motor 17 is placed in the machine base 9, the motor shaft 171 passes through the shaft hole of the machine base 9 upwards, and the motor 17 is fastened on the machine base 9 using fasteners, the end of the motor shaft 171 is connected with a clutch A 13, the machine The top of the seat 9 is provided with a sheet metal 8 supporting the cup body, the sheet metal 8 is connected to the buckle 7 by the shaft 21, the hook 7 is connected to an elastic member 18, and the elastic member 18 is connected to a cover-opening button 19, when the cover-opening button 19 is pressed At this time, the elastic member 18 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com