Method for preparing bone tissue repairing material by using Arabic gum

A technology of gum arabic and repairing material, applied in the field of preparing bone tissue repairing materials, can solve the problems of low mechanical strength, fast degradation and high degree of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

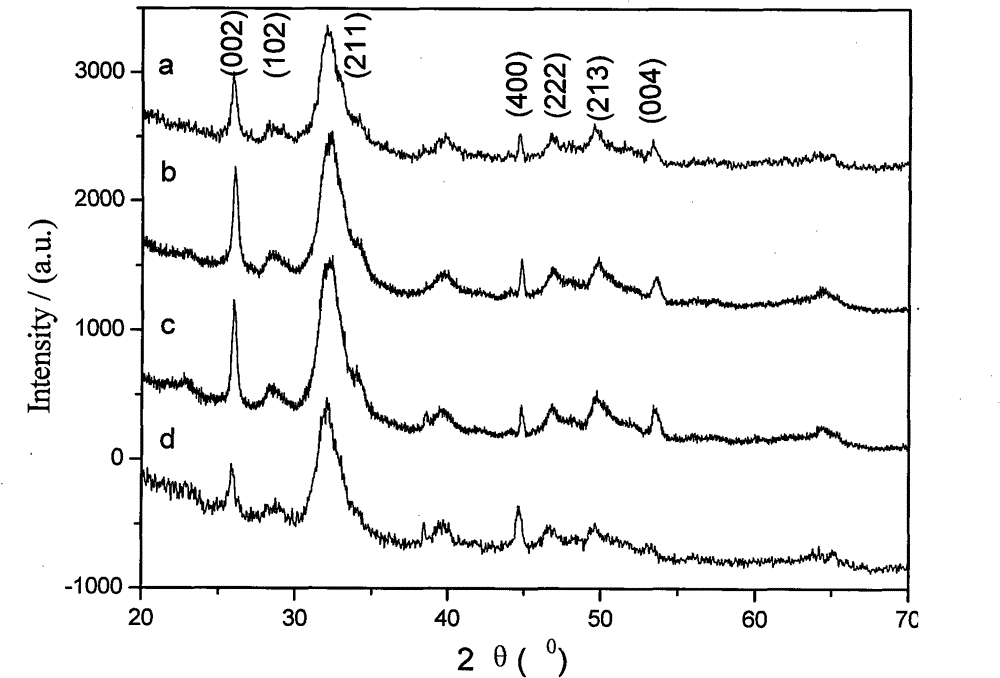

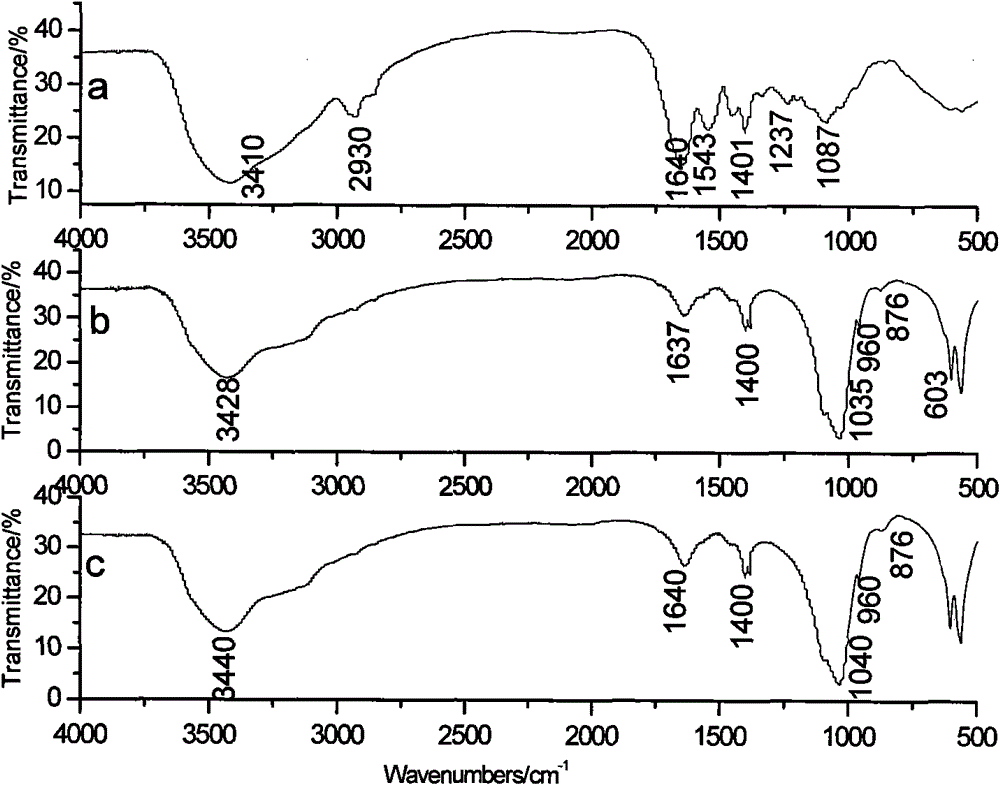

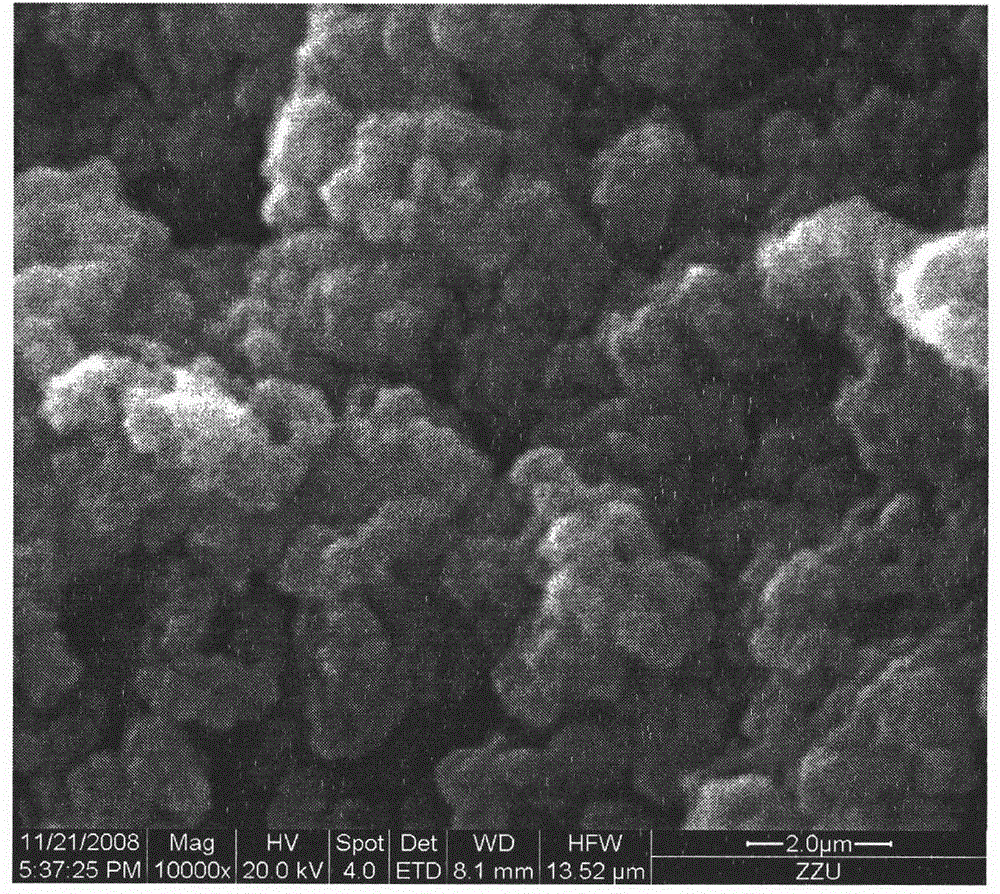

Image

Examples

Embodiment 1

[0022] The method for using gum arabic to prepare bone tissue repair materials, the steps are:

[0023] Take acetic acid aqueous solution with pH=3.0, dissolve collagen in it to prepare an acidic collagen aqueous solution with a concentration of 0.5% by weight; control the ambient temperature at 4°C, take 300mL of the prepared acidic collagen aqueous solution and perform the following operations:

[0024] 1) Add Na to the acidic collagen aqueous solution 2 HPO 4 Make its concentration reach 0.02mol / L, then add NaOH aqueous solution to adjust the pH value to 7.0 to obtain a near-neutral collagen solution;

[0025] 2) Mix the near-neutral collagen solution with 30 mL of gum arabic solution with a concentration of 5wt% (the weight ratio of collagen to gum arabic is 1:1), adjust the pH value to 7.0, stir for 20 minutes to make the system uniform, and obtain collagen / gum arabic mixture;

[0026] 3) Adjust the pH value of the collagen / gum arabic mixed solution to 7.2 with ammonia...

Embodiment 2

[0029] The method for using gum arabic to prepare bone tissue repair materials, the steps are:

[0030] Take acetic acid aqueous solution with pH=2.5, dissolve collagen in it to prepare 0.8wt% acidic collagen aqueous solution; control the ambient temperature at 6°C, take 187.5mL of prepared acidic collagen aqueous solution and perform the following operations:

[0031] 1) Add Na to the acidic collagen aqueous solution 2 HPO 4 Make its concentration reach 0.01mol / L, then add NaOH aqueous solution to adjust the pH value to 6.0 to obtain a near-neutral collagen solution;

[0032] 2) Mix the near-neutral collagen solution with 15 mL of gum arabic solution with a concentration of 5wt% (the weight ratio of collagen to gum arabic is 2:1), adjust the pH value to 6.0, stir for 18 minutes to make the system uniform, and then obtain collagen / gum arabic mixture;

[0033] 3) Adjust the pH value of the collagen / gum arabic mixed solution to 7.0 with NaOH aqueous solution, and then slowly ...

Embodiment 3

[0036] A method for preparing a bone tissue repair material by using gum arabic, the steps of which are as follows:

[0037]Take hydrochloric acid aqueous solution with pH=2.7, dissolve collagen in it to prepare 0.6wt% acidic collagen aqueous solution; control the ambient temperature at 10°C, take 412.5mL of prepared acidic collagen aqueous solution and perform the following operations:

[0038] 1) Add Na to the acidic collagen aqueous solution 2 HPO 4 Make its concentration reach 0.02mol / L, then add ammonia water to adjust the pH value to 6.6 to obtain a near-neutral collagen solution;

[0039] 2) Mix the near-neutral collagen solution with 16.5mL of 5wt% gum arabic solution (the weight ratio of collagen to gum arabic is 3:1), adjust the pH value to 6.6, stir for 10min to make the system uniform, and obtain collagen / arabic Gum mixed solution;

[0040] 3) Adjust the pH value of the collagen / gum arabic mixed solution to 8 with ammonia water, then slowly add 96 mL of 1.2 mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com