Single power supply single-surface serial double-TIG (Tungsten Inert Gas) arc welding method

An arc welding method and a single power supply technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of space accessibility limitation of the back welding gun synchronously controlled by two guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

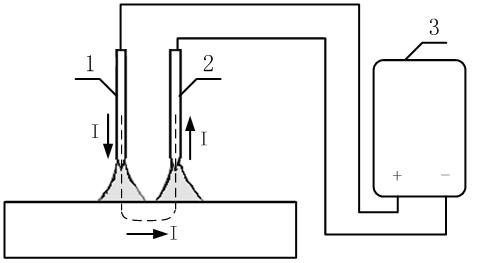

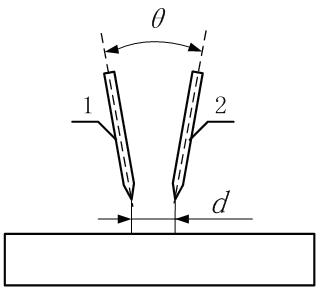

[0014] Specific implementation mode one : The double TIG arc welding method of single power supply and single side series connection of the present embodiment, it adopts a welding power supply 3 and two welding torches, and described two welding torches are the first TIG welding torch 1 and the second TIG welding torch 2;

[0015] The first TIG welding torch 1 is connected to the positive output terminal of the welding power supply 3, and the second TIG welding torch 2 is connected to the negative output terminal of the welding power supply 3;

[0016] During welding, turn on the welding power supply 3 so that the first TIG welding torch 1 and the second TIG welding torch 2 are on the same surface to be welded of the workpiece to be welded, and the current follows the "first TIG welding torch 1 - the workpiece to be welded - the second TIG welding torch" 2" direction, a molten pool is generated between the first TIG welding torch 1 and the workpiece to be welded, and between ...

specific Embodiment approach 2

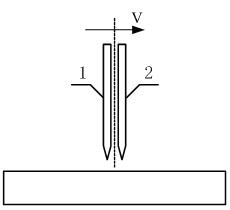

[0025] Specific implementation mode two : This embodiment is a further limitation to Embodiment 1. In the single-power single-sided series double TIG arc welding method of this embodiment, the first TIG welding torch 1 and the second TIG welding torch 2 are arranged in front and back along the welding direction for welding, and the second The TIG welding torch 2 remelts the weld bead of the first TIG welding torch 1 . see image 3 , where V represents the moving direction of the welding torch.

specific Embodiment approach 3

[0026] Specific implementation mode three : This embodiment is a further limitation to Embodiment 1 or 2. In the single-power, single-sided series-connected double TIG arc welding method of this embodiment, the first TIG welding torch 1 and the second TIG welding torch 2 are arranged horizontally perpendicular to the welding direction for welding . see Figure 4 , where V represents the moving direction of the welding torch, and the vertical paper faces inward in the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com