Method for recycling ball milled agent in hard alloy mixed slurry

A cemented carbide and mixed slurry technology, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low recovery rate, difficult promotion, expensive recovery equipment, etc., to increase manufacturing costs and save Energy, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

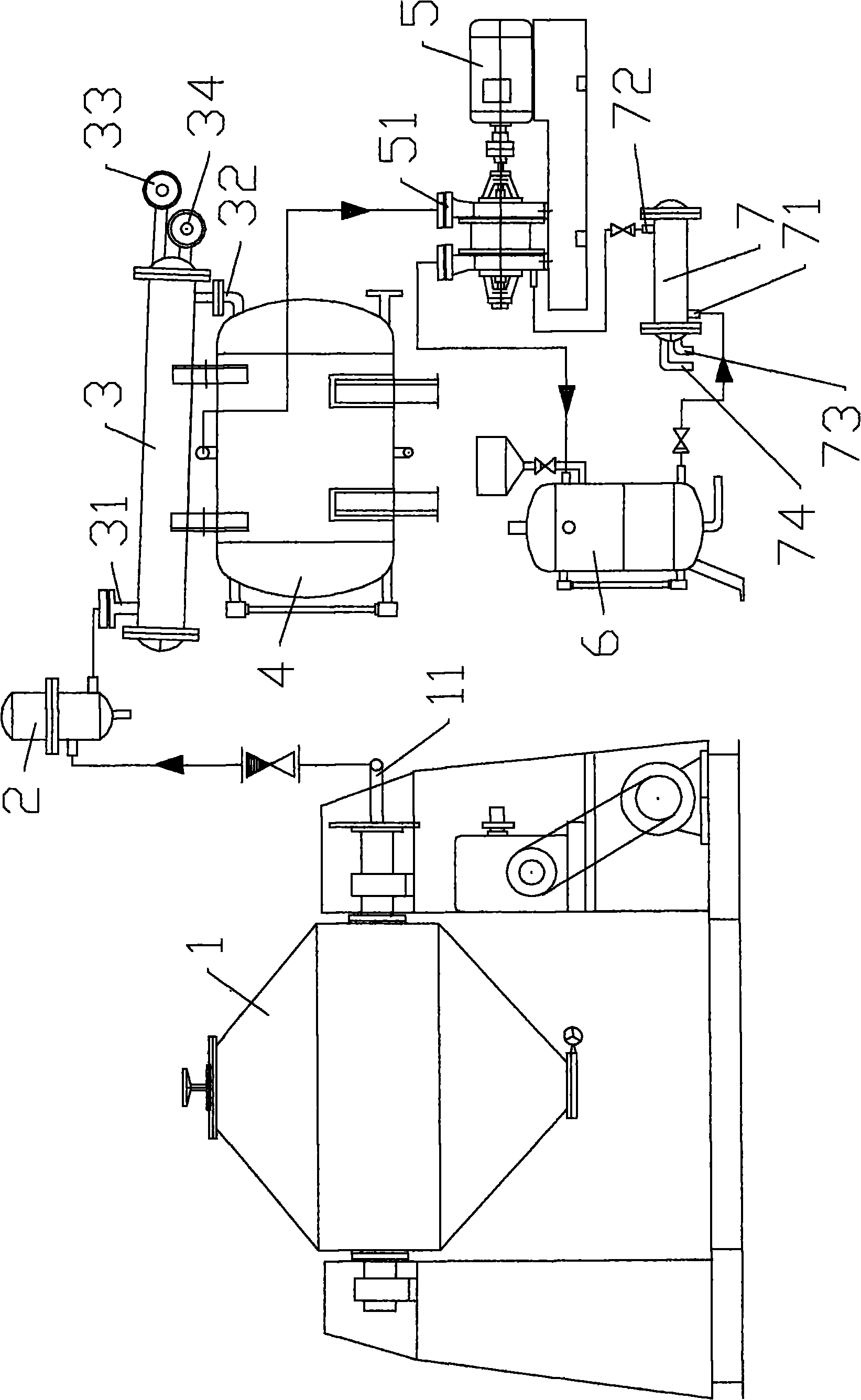

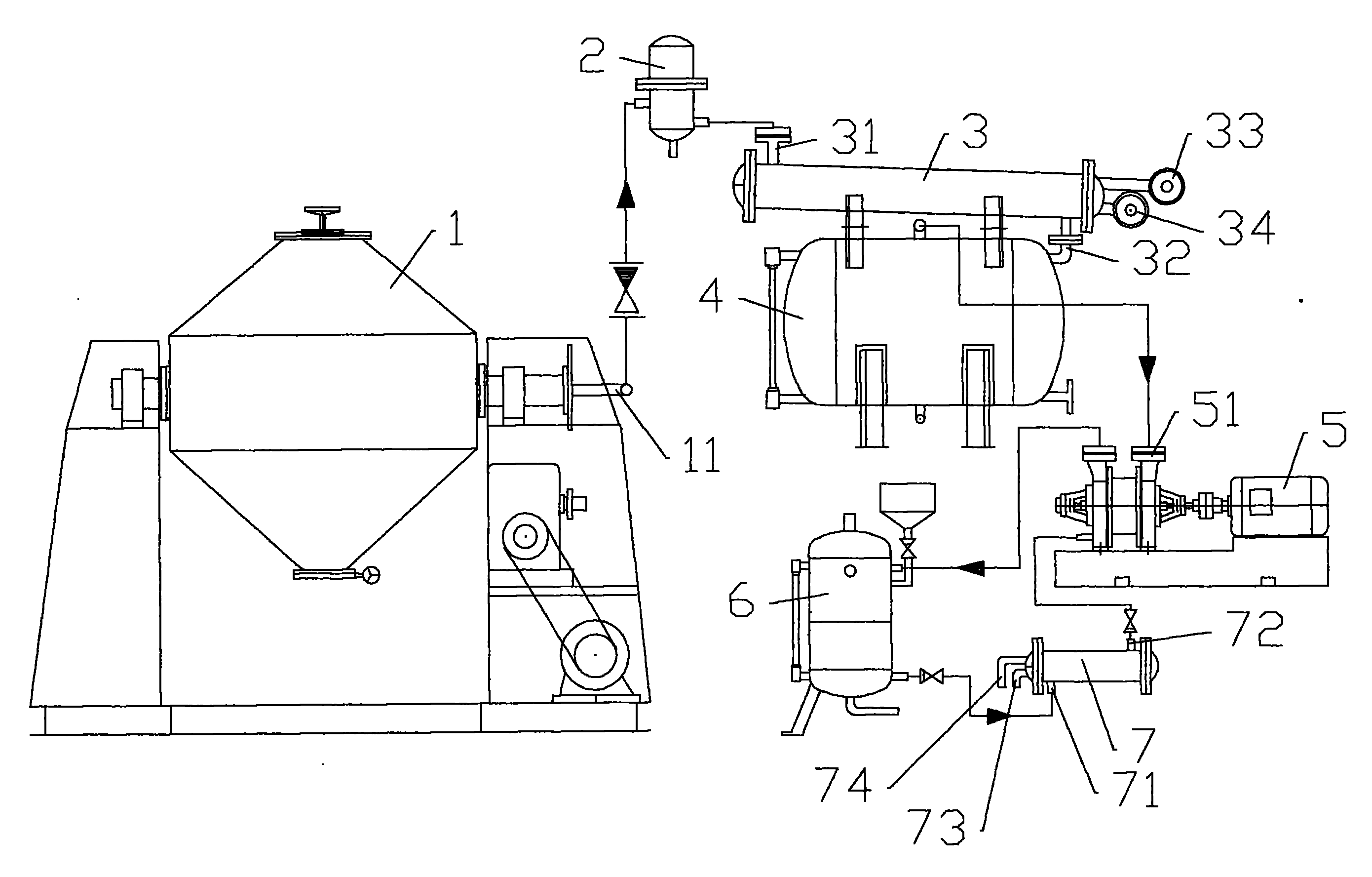

[0016] see figure 1 The ball grinding agent recovery system in the cemented carbide mixed slurry shown includes a vacuum double-cone dryer 1, a filter 2, a tube condenser 3, and a storage tank 4 connected in series. The evacuation tube 11 of the vacuum double-cone dryer 1 communicates with the air inlet of the filter 2, and the air extraction port of the filter 2 communicates with the heat medium channel inlet 31 of the tube condenser 3; the heat medium channel outlet of the tube condenser 3 32 connects the top of storage tank 4. The refrigerant of the tube condenser 3 is chilled water, and the chilled water enters the tube condenser from the inlet 33 of the refrigerant channel and flows out from the outlet 34 of the refrigerant channel.

[0017] The upper part of the storage tank 4 communicates with the suction port 51 of the water ring vacuum pump 5 . The water outlet of the water ring vacuum pump 5 is connected to the upper part of the liquid tank 6, the bottom of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com