Mobile type building block solar energy curing and production line

A solar-powered, mobile technology, used in ceramic molding workshops, stacking of objects, de-stacking of objects, etc., can solve problems such as affecting the yield rate and damage to the underlying blocks, improving efficiency, reducing breakage rates, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

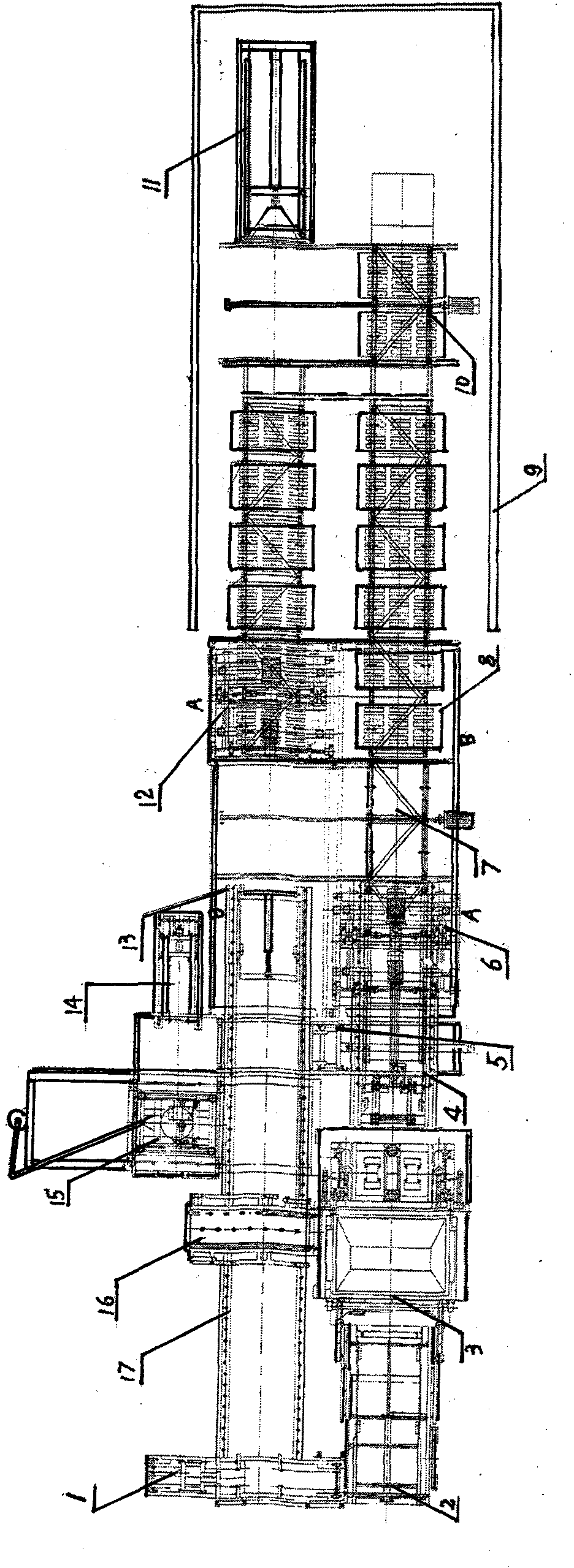

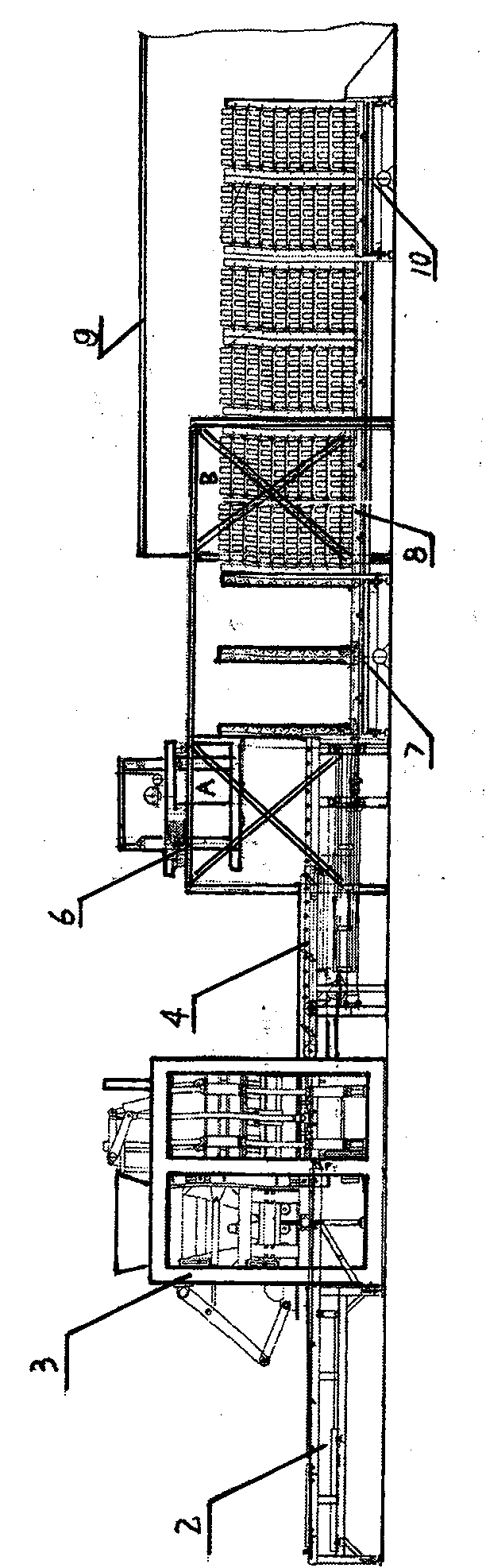

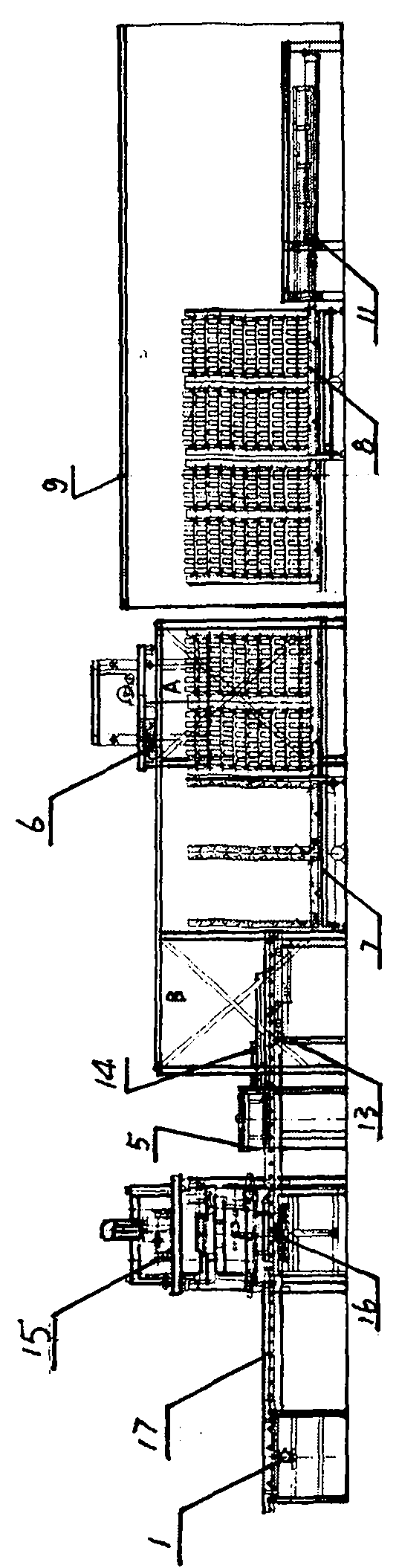

[0039] See attached figure 1 , figure 2 , image 3 The mobile block solar maintenance and production line shown in the figure includes the trigger 2, forming machine 3, crossing bridge 4, plate loading machine 6, front traverse mechanism 7, and layered maintenance trolley 8, which are arranged vertically and sequentially. On the side of the entrance of the chamber 9, the terminal of the solar energy collection chamber 9 has a rear traversing propulsion mechanism 10 and a longitudinal propulsion mechanism 11 at one end; an unloader 12 and a pusher are arranged on the side of the exit of the solar energy concentration chamber 9 13. Brick pushing machine 5, plate turning machine 16, dry area running frame 17 and plate feeding machine 1 arranged horizontally; the plate feeding machine 1 is connected with plate feeding machine 2; Block palletizing man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com