Detection device of subsurface defect of optical element and method thereof

A technology for subsurface defects and optical components, applied in the direction of optical testing flaws/defects, etc., can solve the problems of measurement result error, unreliable depth and topography measurement results, etc., to avoid measurement errors, optimize grinding and polishing processes, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

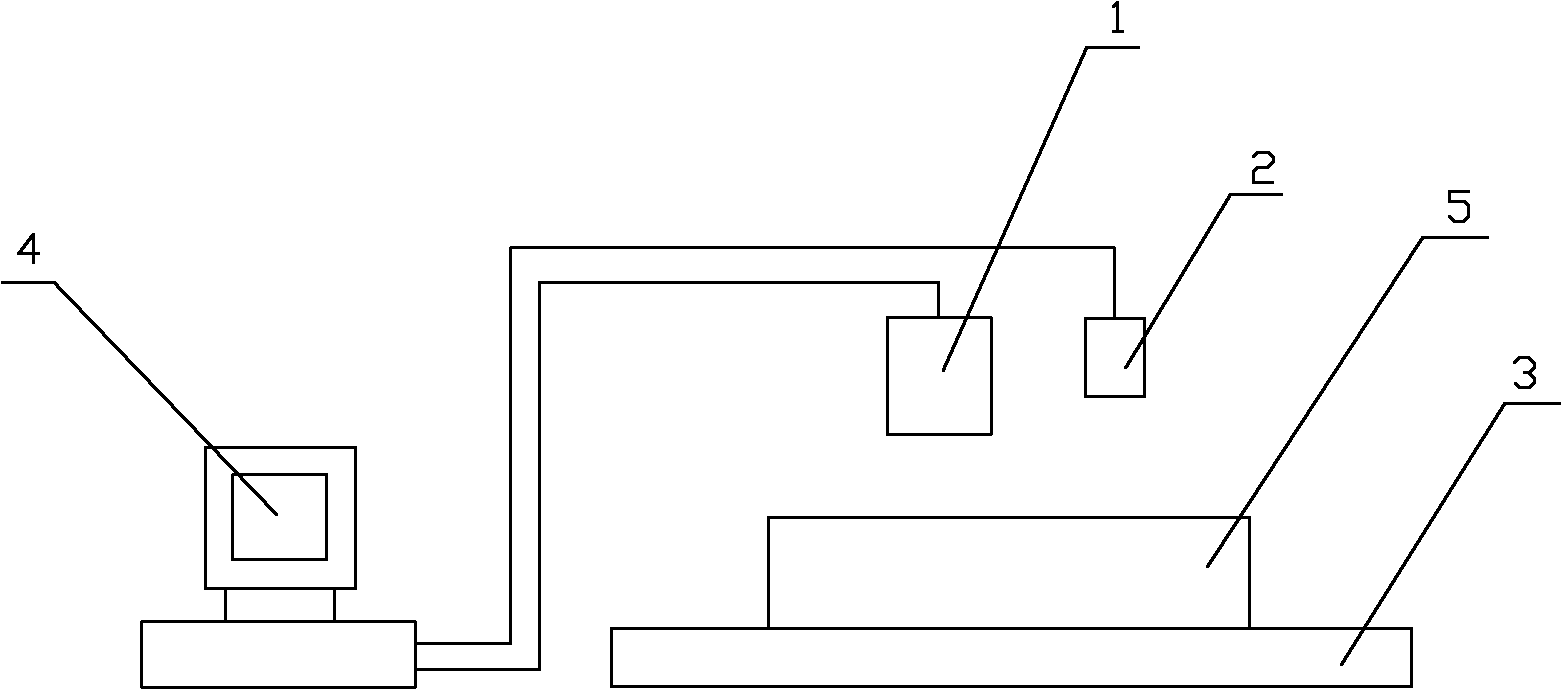

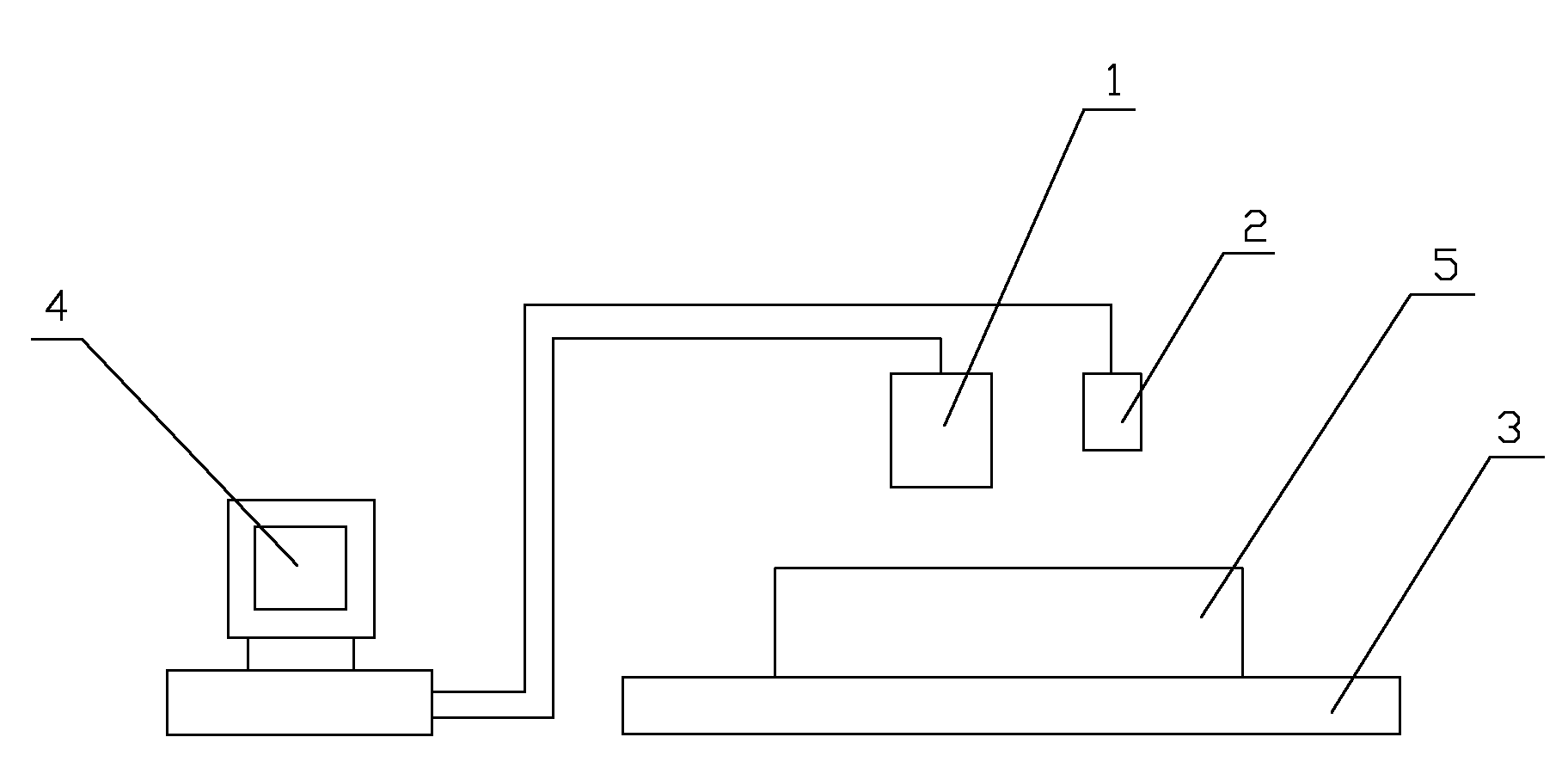

[0009] Such as figure 1 As shown, the measuring device of the present invention includes: a microscope 1, a laser displacement sensor 2, a precision displacement platform 3, and an image data processing unit 4, and the image data processing unit 4 is connected to the microscope 1 and the laser displacement sensor 2 respectively. Microscope 1 has a lens with high magnification and large numerical aperture and a lens with low magnification and wide field of view. The wide field of view lens is used for preliminary positioning of the measured area, and the high magnification lens is used for precise focusing to measure the depth of subsurface defects and observe subsurfaces defect morphology. The laser displacement sensor 2 is used to measure the movement amount of the precision displacement platform 3 in the Z direction, and the laser displacement sensor 2 has a measurement accuracy above submicron level. The precision displacement platform 3 is used to place the sample 5 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com