Standard sample dilution deviation tracking and correcting system calibrated by gas analyzer on line and method thereof

A gas analysis and analysis instrument technology, applied in the field of test analysis technology and analysis instrument process integration, to achieve the effect of simple operation process, easy control, and reduction of standard sample concentration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

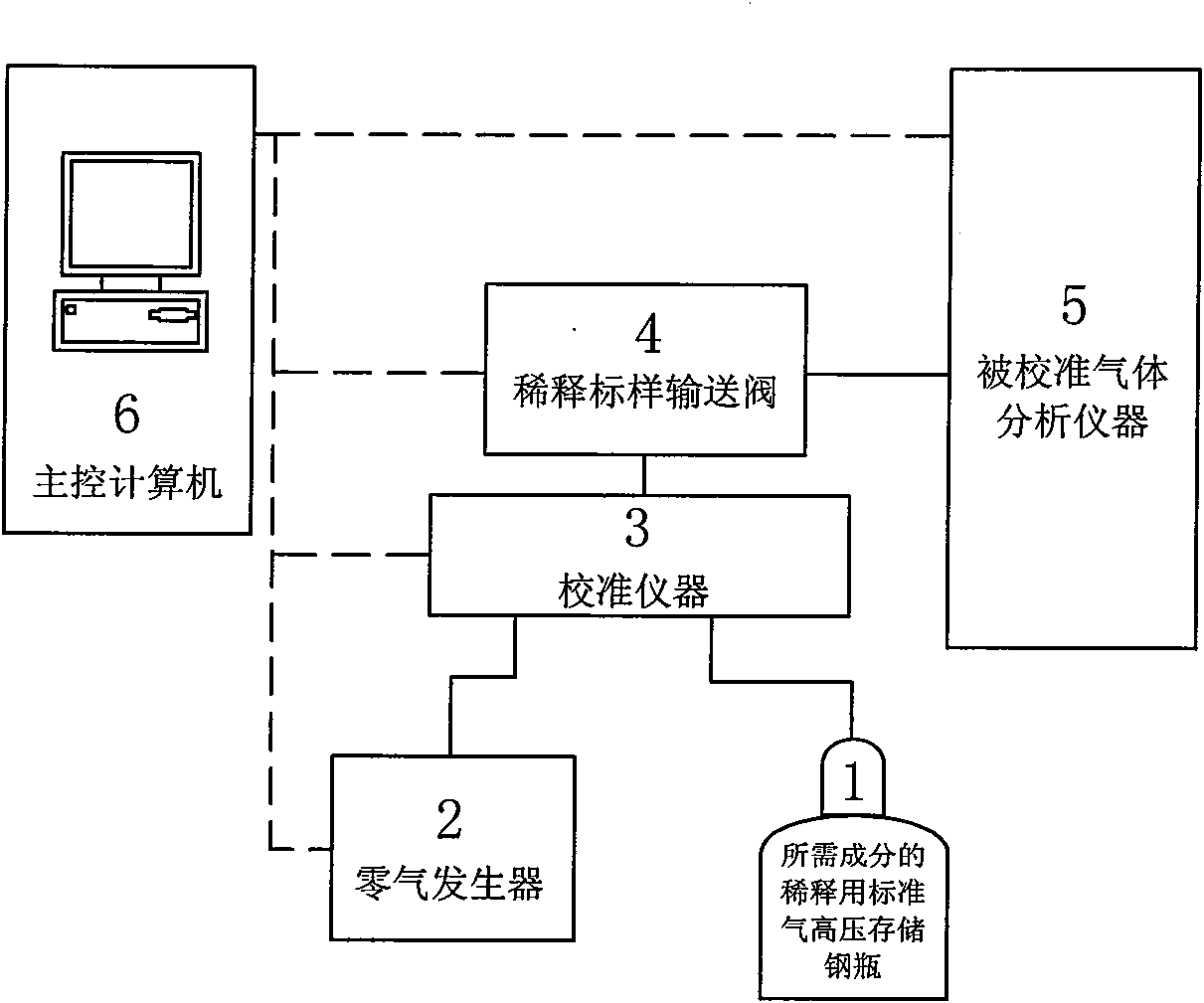

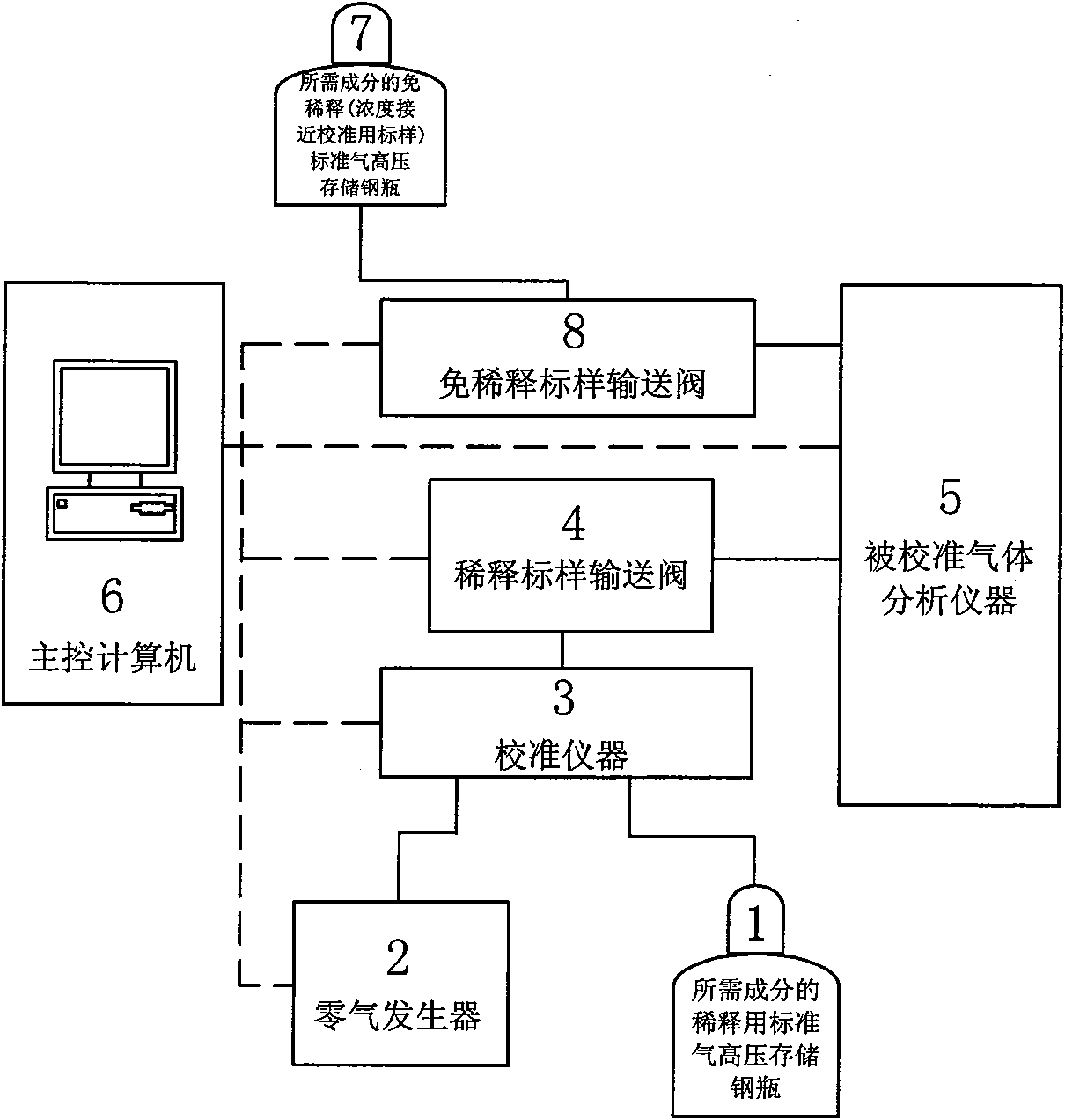

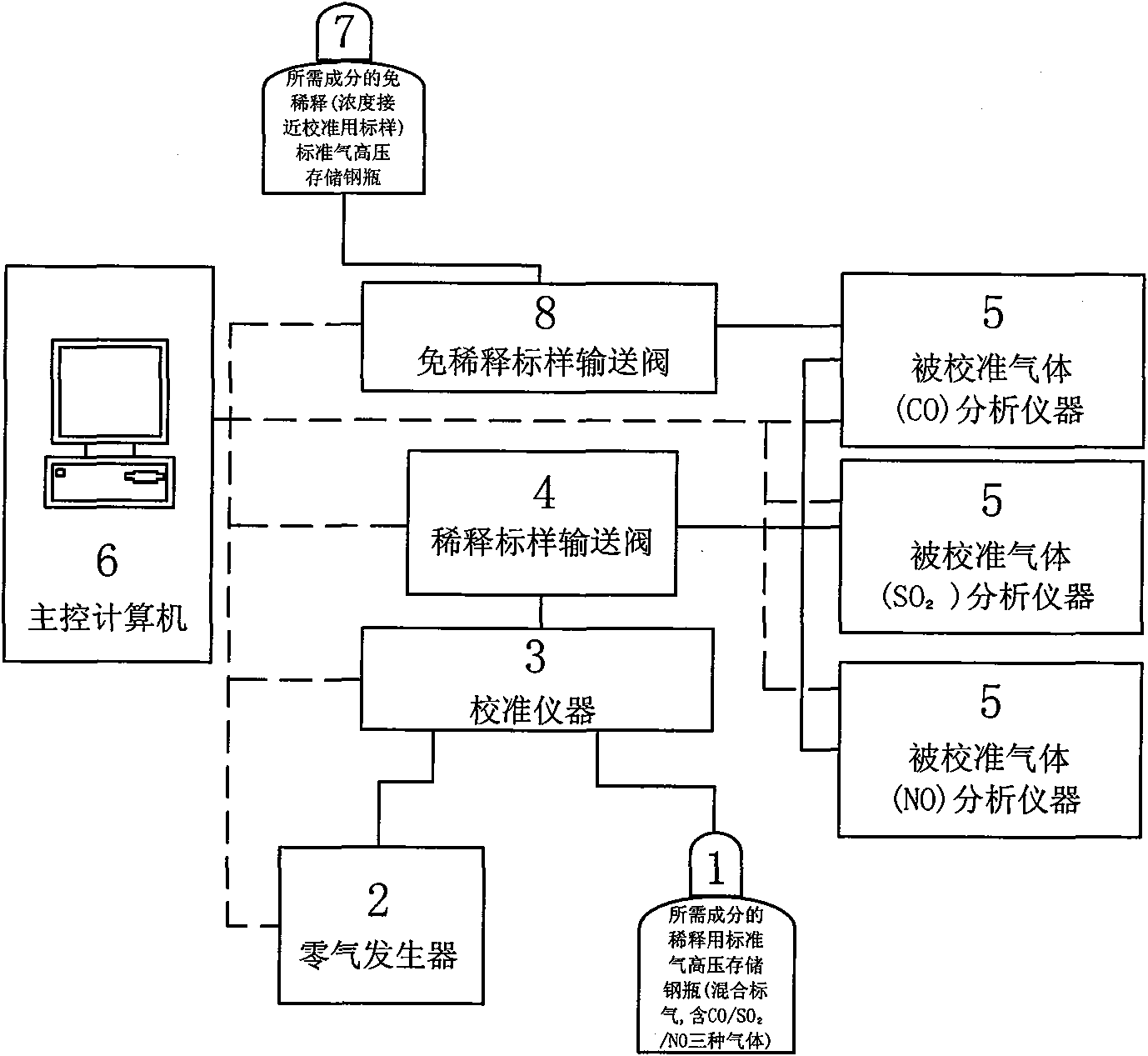

[0047] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0048] In the present invention, the quantitative calculation of the dilution deviation is to utilize the standard gas of the analysis item with good stability and accuracy—such as CO standard gas, by directly delivering the concentration of the standard sample close to the calibration to the project analysis instrument The trace effect produced between the standard gas (no-dilution standard sample) and the calibration standard sample (diluted standard sample) prepared by the dynamic dilution of the delivery calibration instrument, calculate the calibration instrument near the standard gas flow and zero gas flow, with dilution bias.

[0049] In principle, the dilution deviation of the calibration instrument only reflects the influence of the measurement error of standard gas flow and zero gas flow, and does not change due to the preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com