Solder resist coating for rigid-flex circuit board

A rigid-flex bonding, solder resist technology, applied in the direction of circuit bendable/stretchable parts, printed circuits, printed circuits, etc., can solve the problems of wasting time, high cost, avoid peeling, prolong life, life improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the description of the embodiments of the invention, the terms "upper", "lower", and the underside and upper side of the circuit board are used as reflected in the figures. It is however clear to those skilled in the art that such terms may be used interchangeably where possible.

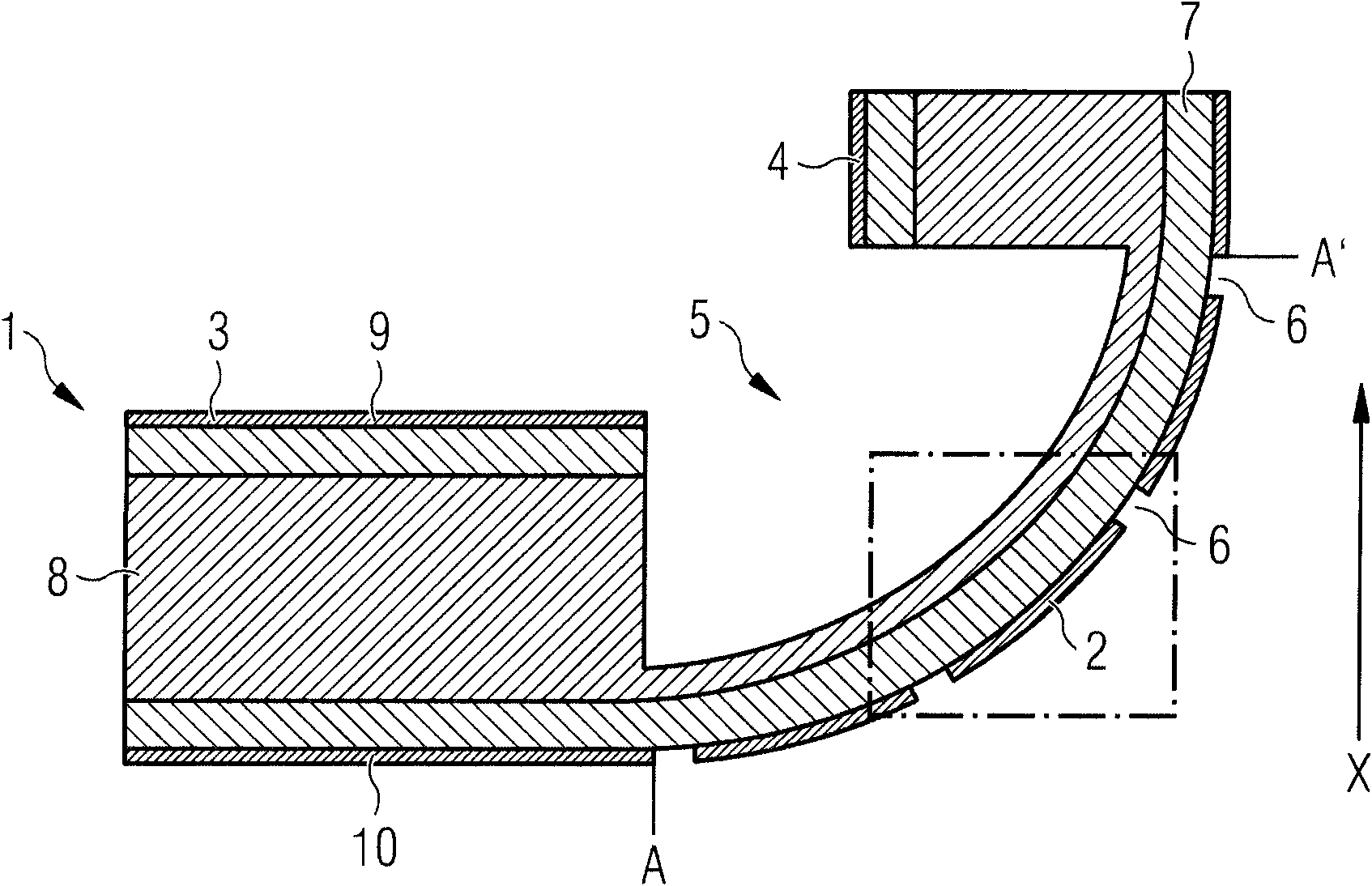

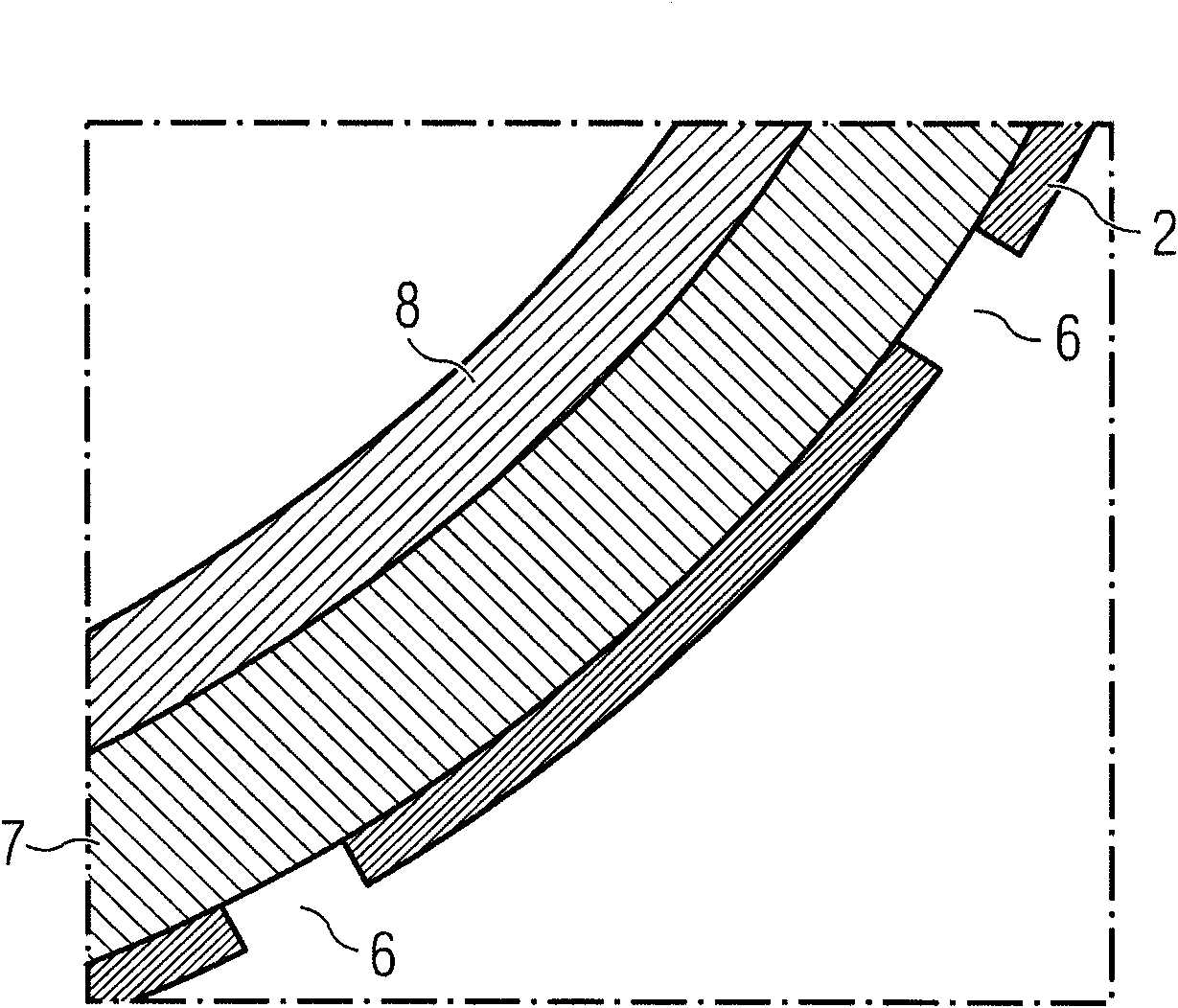

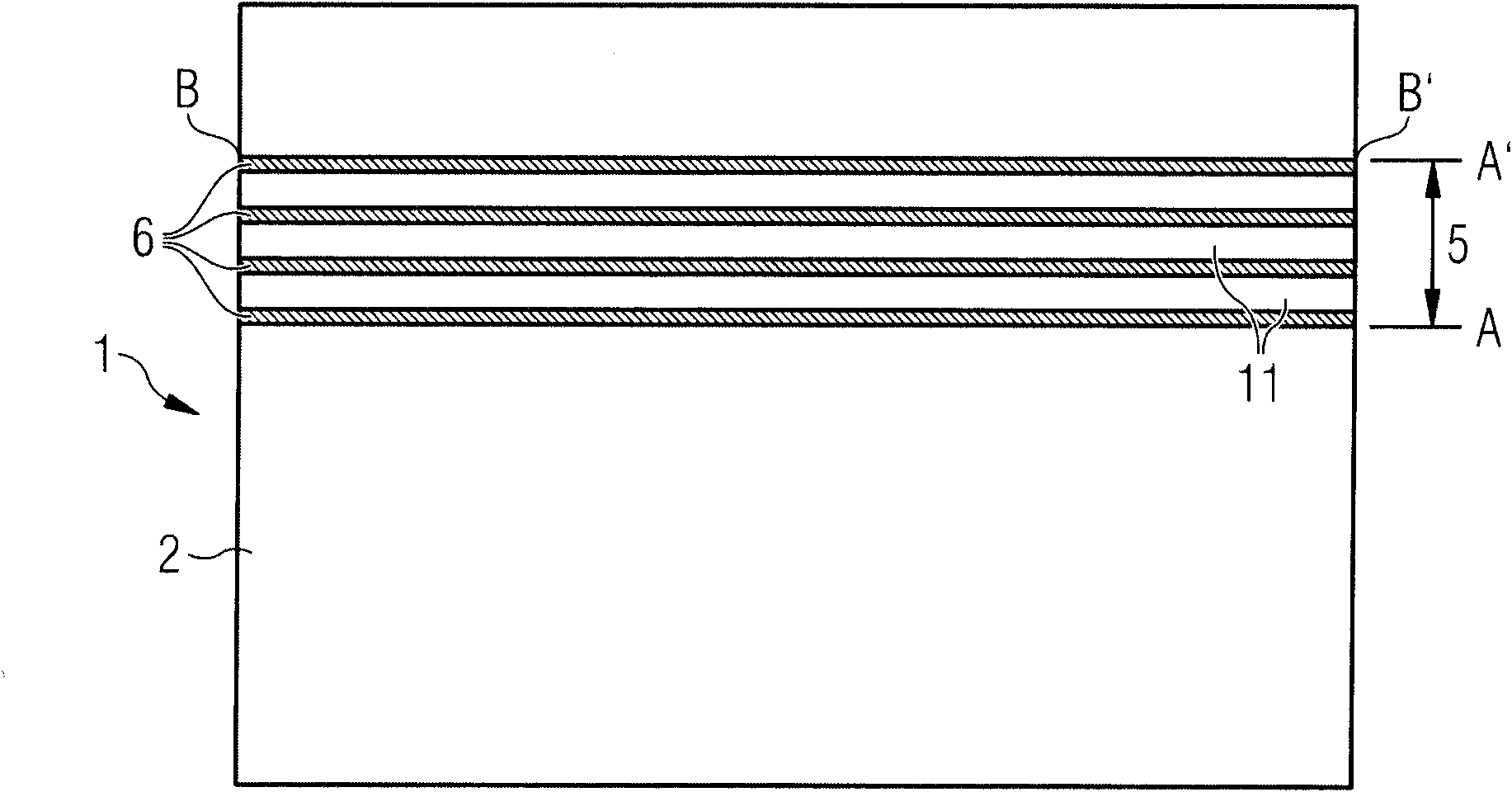

[0033] figure 1 A cross-sectional view of a rigid-flex circuit board 1 with a solder resist varnish layer 2 according to the invention is shown. The rigid-flex circuit board 1 has a first rigid area 3 and a second rigid area 4 . Between the rigid regions 3 and 4 is arranged a bending region 5 in which the printed circuit board 1 is designed to be flexible. In the bending region 5 extending over the length A-A', the circuit board 1 can be made of a rigid circuit board material with a small thickness. The bending area 5 can be produced as a recess in the circuit board 1 , for example by deep milling. According to the invention, the solder resist lacquer layer 2 can have one or more expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com