Thin-film fixed bed reactor for the chemical treatment of a finely divided catalytic solid

一种固定床反应器、反应器的技术,应用在催化剂活化/制备、化学仪器和方法、化学/物理过程等方向,能够解决流化床反应器良好分布困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

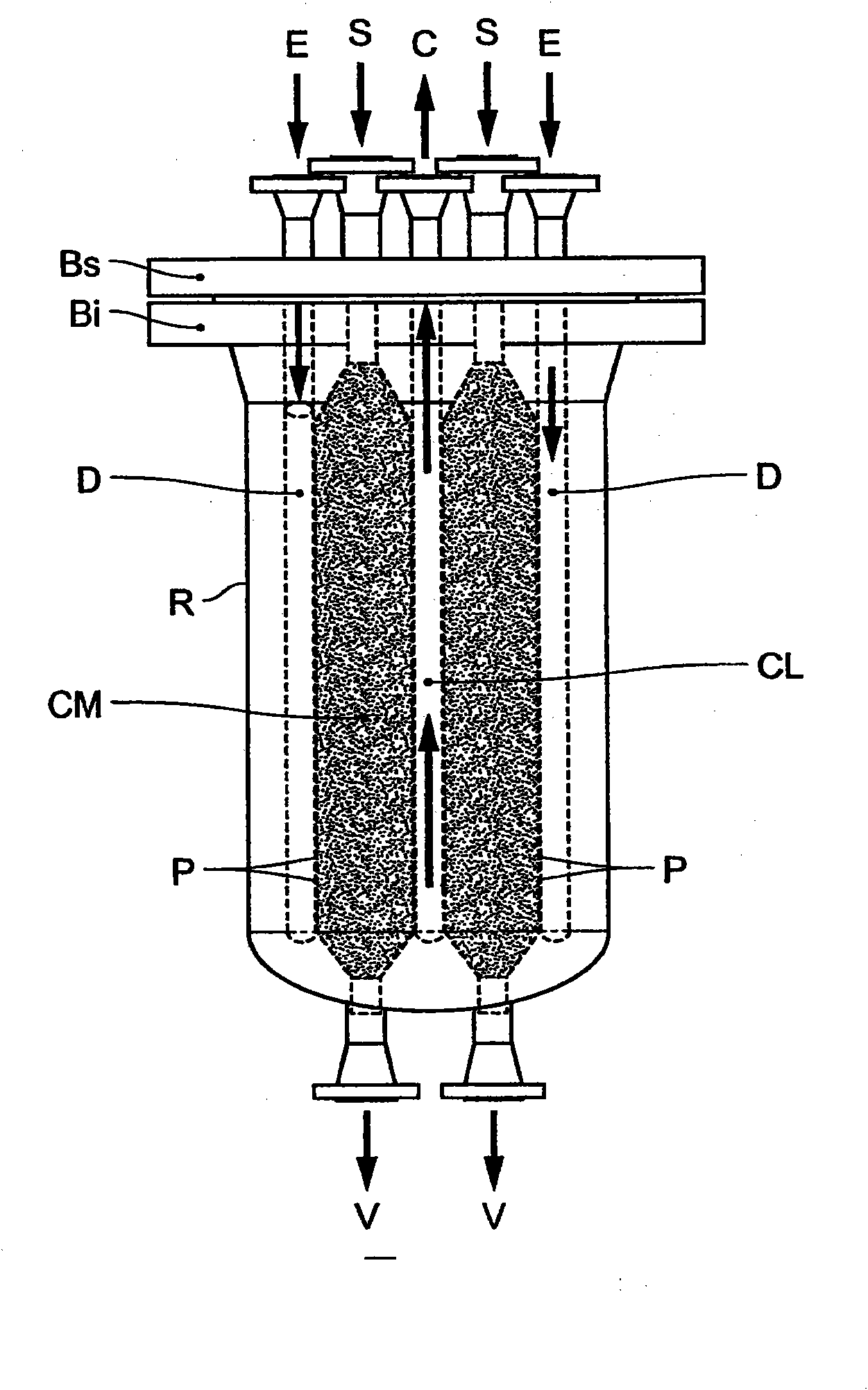

[0092] The following reference corresponds to the planar structure Figure 2a , 2b , 2c for description.

[0093] The invention comprises a fixed-bed reactor with thin layers consisting of modules M-like assemblies operating in parallel and enclosed in a common vessel constituting the envelope R of said reactor.

[0094] In this particular case, the modules are identical.

[0095] The reactor is used to treat catalyst solids in the reactor in the form of fine particles typically in the range of 30 to 100 microns in diameter.

[0096] Said treatment, commonly referred to by those skilled in the art as "reduction", uses a reactive gas, which is hydrogen, optionally diluted with an inert gas (typically nitrogen) at any dilution, but preferably between 25 % to 35% (volume). Each module M of the reactor consists of components comprising the following elements:

[0097] a collector CL for reaction effluents, adjacent to the porous outlet face of said enclosure P;

[0098] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com