Protection system for subsea seawater injection pumps

A pump system and pump cavity technology, applied in the field of pump systems, can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

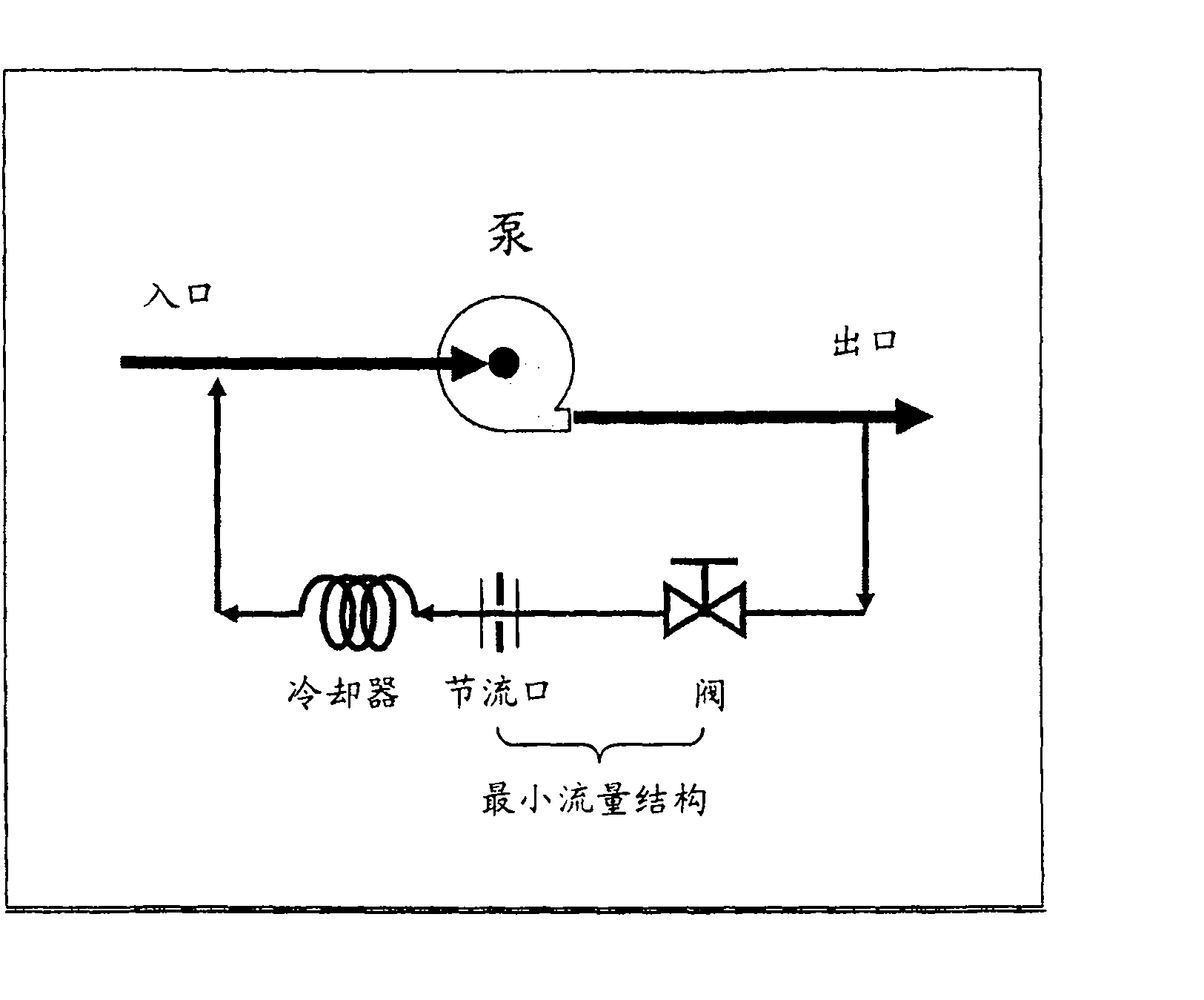

[0011] Current subsea pumping systems employ conventional electric motors having windings with connections that are not fully insulated from the environment and that are filled with dielectric oil that acts as an additional insulator. According to environmental regulations, the discharge of this dielectric oil into the environment is not permitted. For systems utilizing such fluids, such as figure 1 shown, a closed minimum flow loop must be used to protect the pump.

[0012] In a closed cycle, where the same water is circulated, the energy applied to the water by the pump will cause the fluid and thus the pump to overheat and eventually cause damage. Therefore, closed cycle solutions require orifices / chokes, piping and valves to form a closed cycle, and coolers to avoid overheating of the recirculating fluid within the closed cycle.

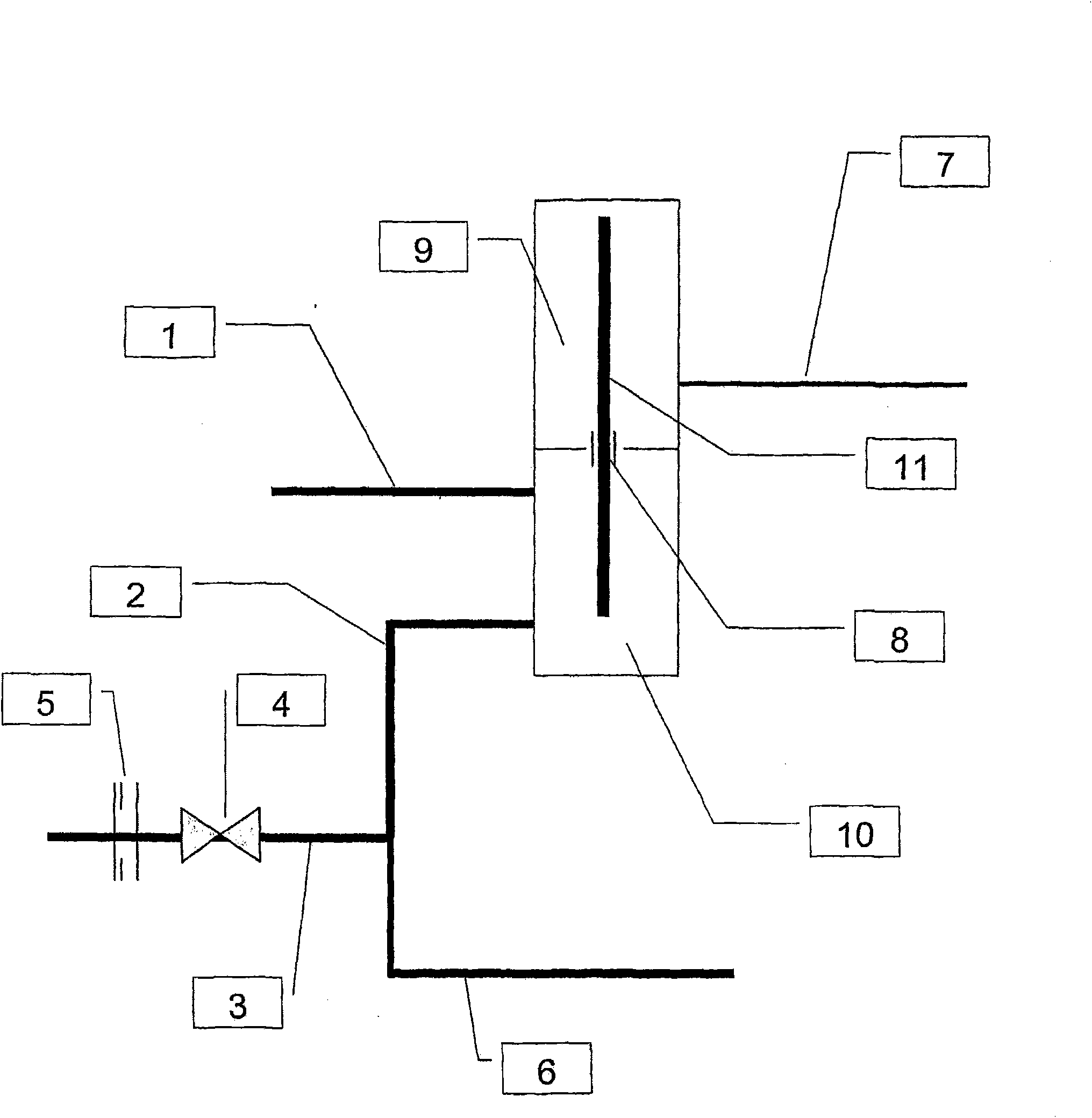

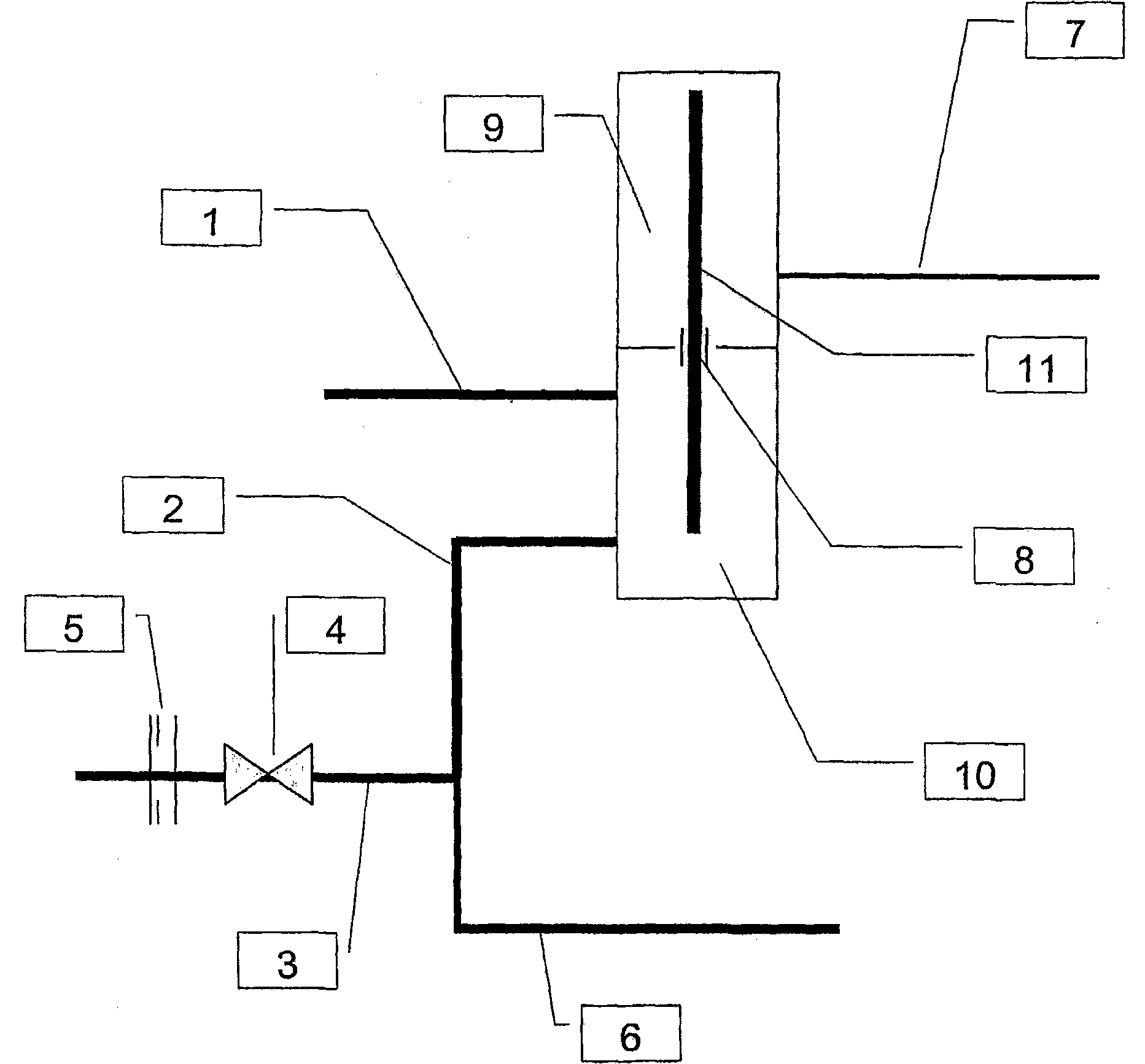

[0013] The present invention, as will be explained below, will significantly reduce the size and number of components required, ultimately res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com