Error processing system of automatic photoelectric crystal furnace and method thereof

An error handling, photoelectric crystal technology, applied in chemical instruments and methods, crystal growth, self-molten liquid pulling method, etc., can solve problems such as safety accidents and crystal quality decline, and achieve the effect of avoiding safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention is based on an automatic photoelectric crystal furnace, and proposes a processing and recording mechanism for software and hardware errors. With the assistance of the invention, the photoelectric crystal furnace has the function of detecting its own working state, and can report errors that occur during operation.

[0023] For crystal preparers, the invention can effectively improve the safety of the crystal preparation process and increase the crystal yield. For crystal equipment designers, the invention can effectively help the designers to debug the equipment, constantly find out defects in software and hardware, and design more safe and reliable crystal preparation equipment.

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

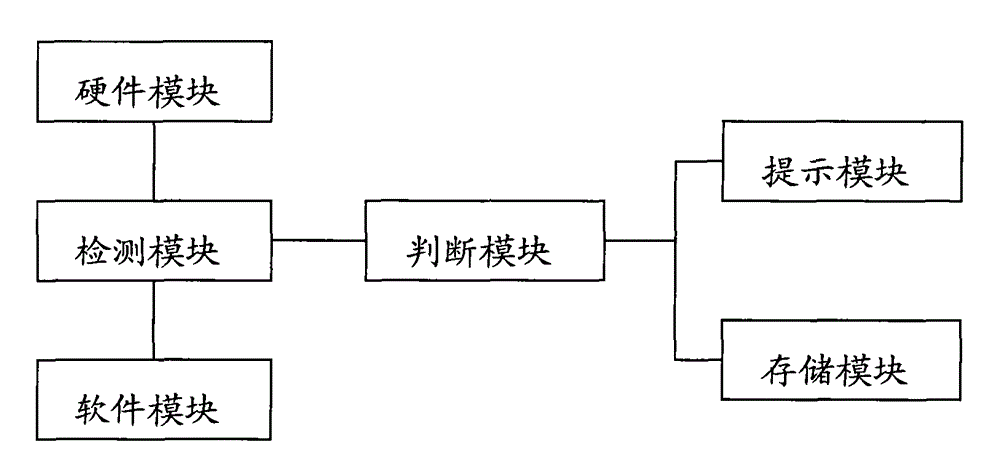

[0025] Such as figure 1 As shown, the present invention discloses an error processing system for an automated optoelectronic crystal furnace, which is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com