Fuel injecting strategy of ignition chamber type direct injection gasoline machine

A technology of fuel injection and ignition chamber, which is applied in the directions of fuel injection control, fuel injection device, charging system, etc., can solve the problems of difficult ignition of the engine, increased emissions, unstable combustion, etc., and achieves rapid and stable flame propagation and stable ignition. Reliable, Reduced Design Complexity Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

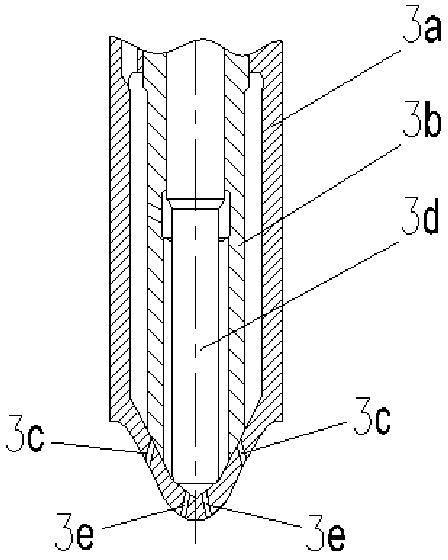

[0025] figure 1 A structure of a double needle valve fuel nozzle is shown. The fuel nozzle 3 includes a needle valve body 3a, an outer needle valve 3b and an inner needle valve 3d, the outer needle valve 3b is arranged in the needle valve body 3a, the inner needle valve 3d is arranged in the outer needle valve 3b, and the needle valve The body 3a is provided with four upper spray holes 3c controlled by the outer needle valve 3b, and the needle valve body 3a is provided with four lower spray holes 3e controlled by the inner needle valve 3d.

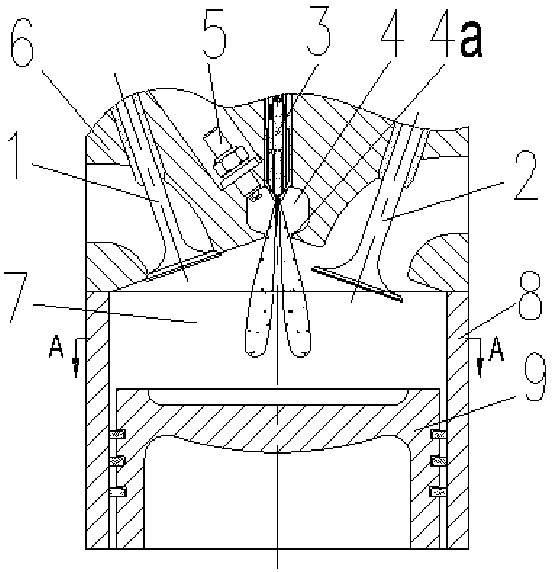

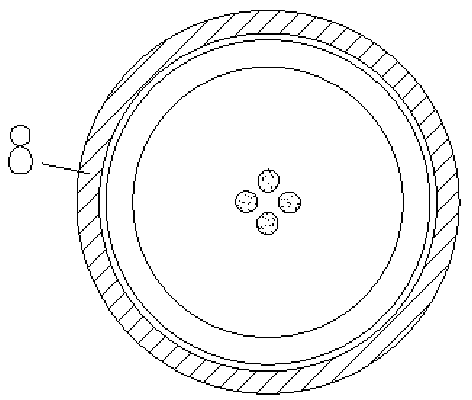

[0026] figure 2 , 3 , 4, 5 show the schematic diagrams of the fuel nozzles arranged inside the ignition chamber. When the fuel nozzle 3 was arranged in the ignition chamber 4, the direction of the lower spray hole 3e which was responsible for the fuel supply of the main combustion chamber 7 was directly aimed at the outlet 4a of the ignition chamber 4, so that the fuel was injected into the main combustion chamber 7; The direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com