Vehicle high-low beam integrated light and control system thereof

A control system, far and near light technology, applied in the field of automotive lighting, can solve the problems of high energy consumption, increased production costs, low brightness, etc., to achieve the effects of reducing production costs, ensuring reliability, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

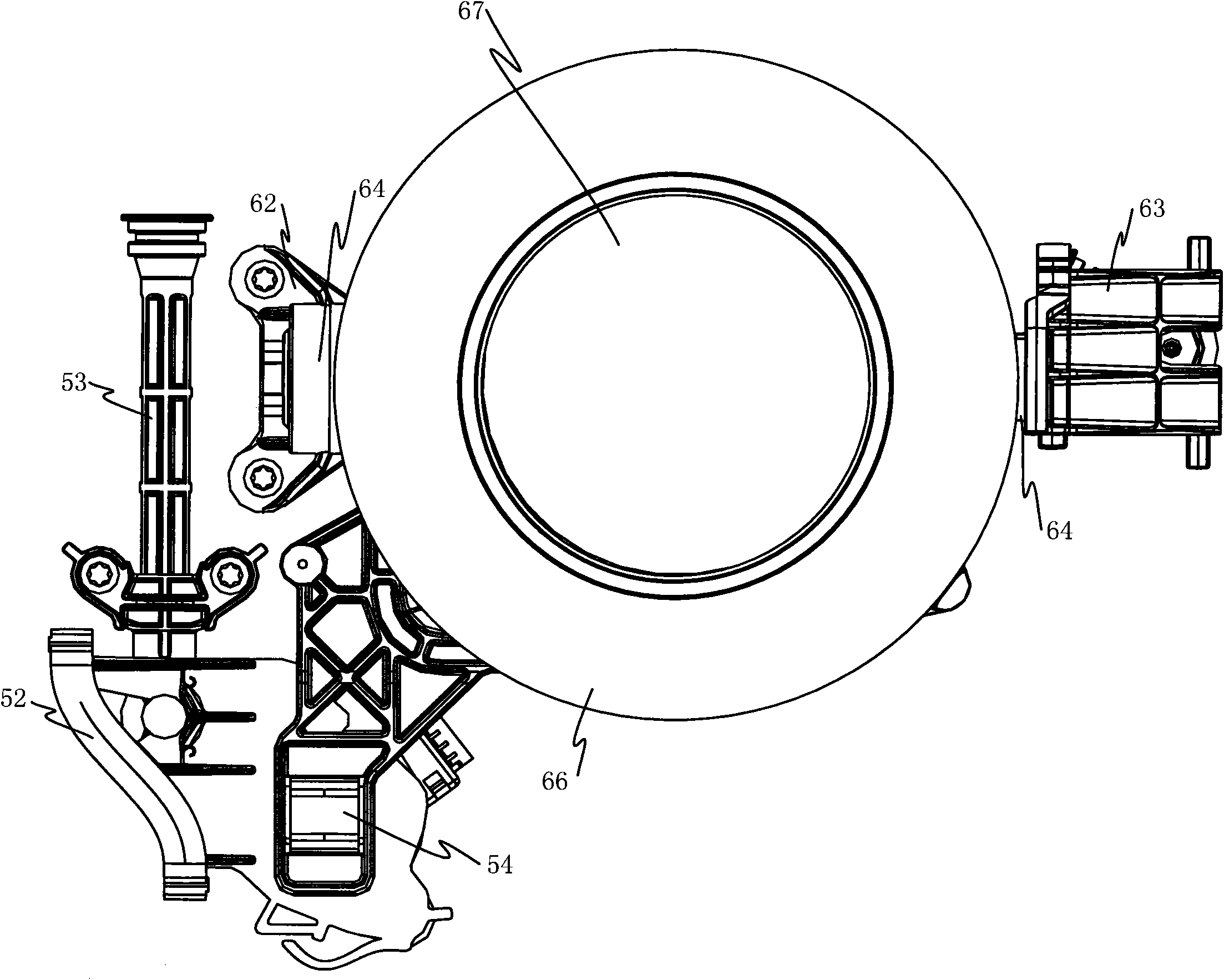

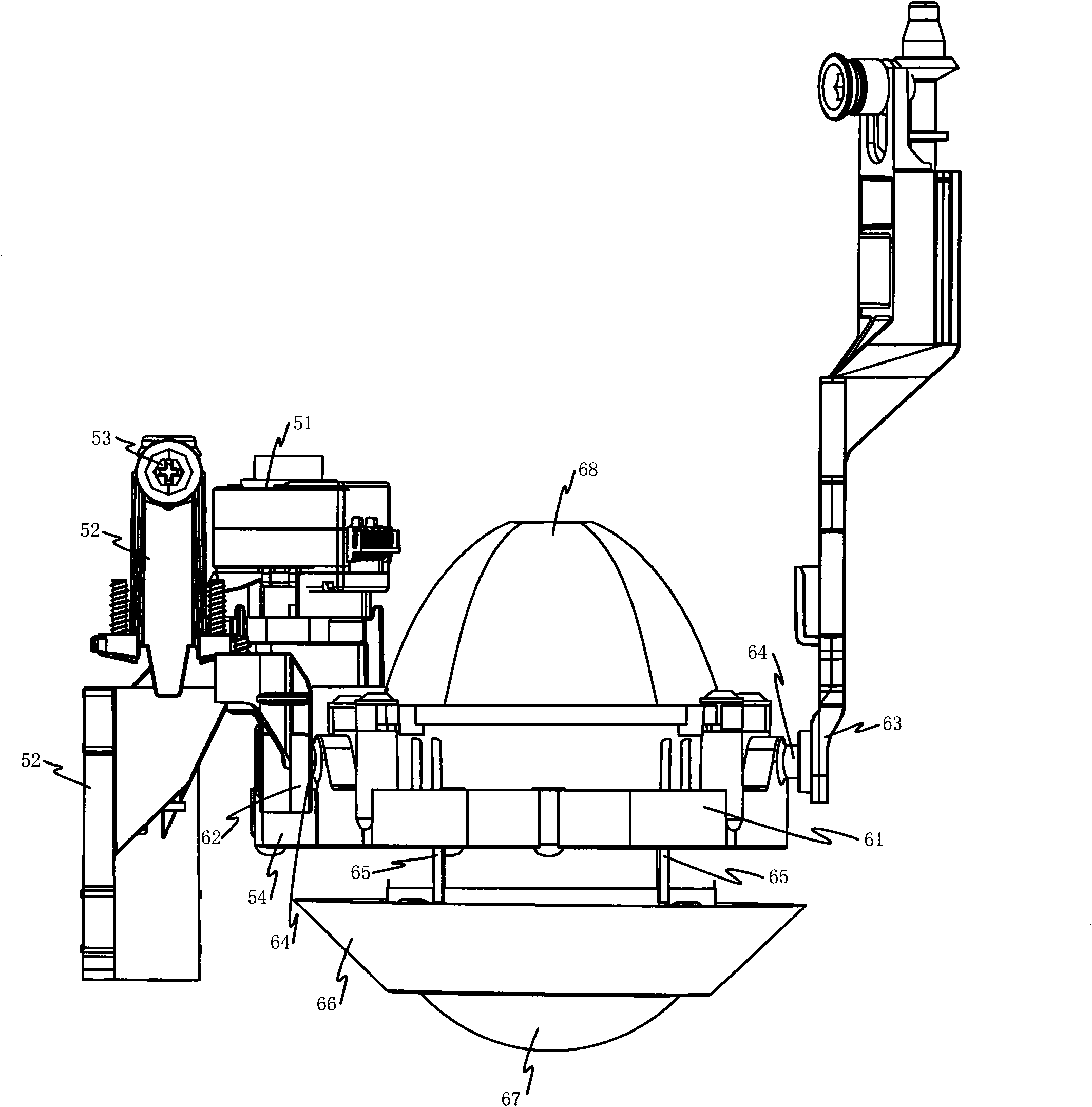

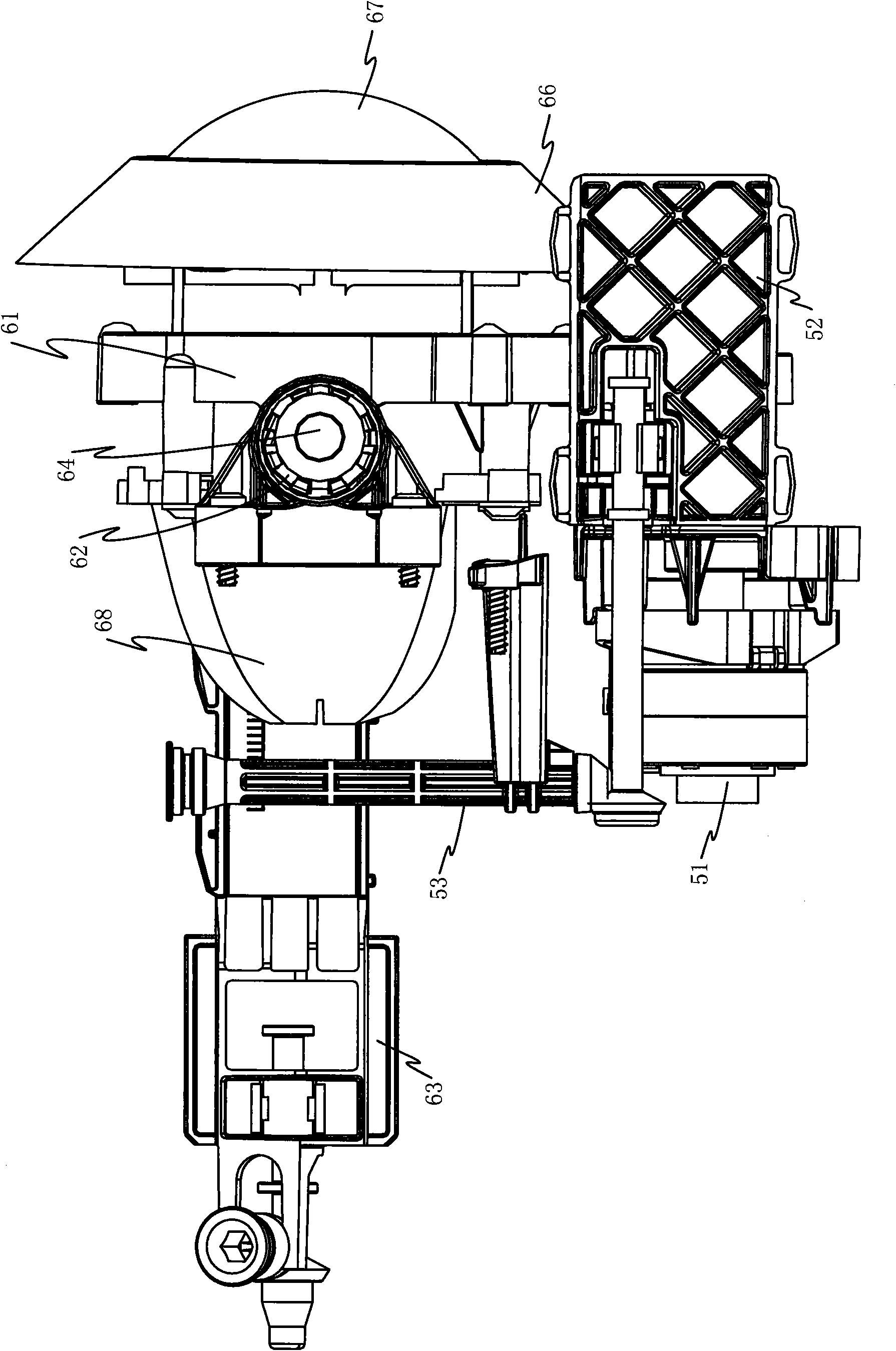

[0013] An integrated far and near beam lamp for vehicles, comprising a reflective bowl 68, the lamp body is installed in the reflective bowl 68, the lamp body is a xenon lamp, the light source of the xenon lamp has high brightness, and a single xenon lamp can meet the requirements of far and near light at the same time. Light needs. A support is provided at the mouth of the reflective bowl 68, and the support is connected to the drive shaft 54 of the driving device 50. The drive shaft 54 of the drive device 50 drives the support to make the reflective bowl 68 rotate around a horizontal axis perpendicular to the vehicle's driving direction. When the lamp body is tilted downward, it emits a low beam. On the contrary, when the lamp body is basically in a horizontal position, it emits a high beam. figure 1 , 2 , 3 shown.

[0014] combine figure 1 , 2 3. The support includes a first support 61 fixed at the mouth of the reflective bowl 68, the first support 61 is frame-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com