Method for manufacturing finite element method mechanical computation model of pipeline system

A finite element and calculation model technology, applied in the pre-processing field of pipeline finite element calculation, can solve the problems of long time required for pipeline calculation, affecting the calculation efficiency of nuclear-grade pipeline mechanics in nuclear power plants, and the large amount of calculation of nuclear power plant pipelines, etc., to achieve efficiency improvement , the effect of reducing the requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

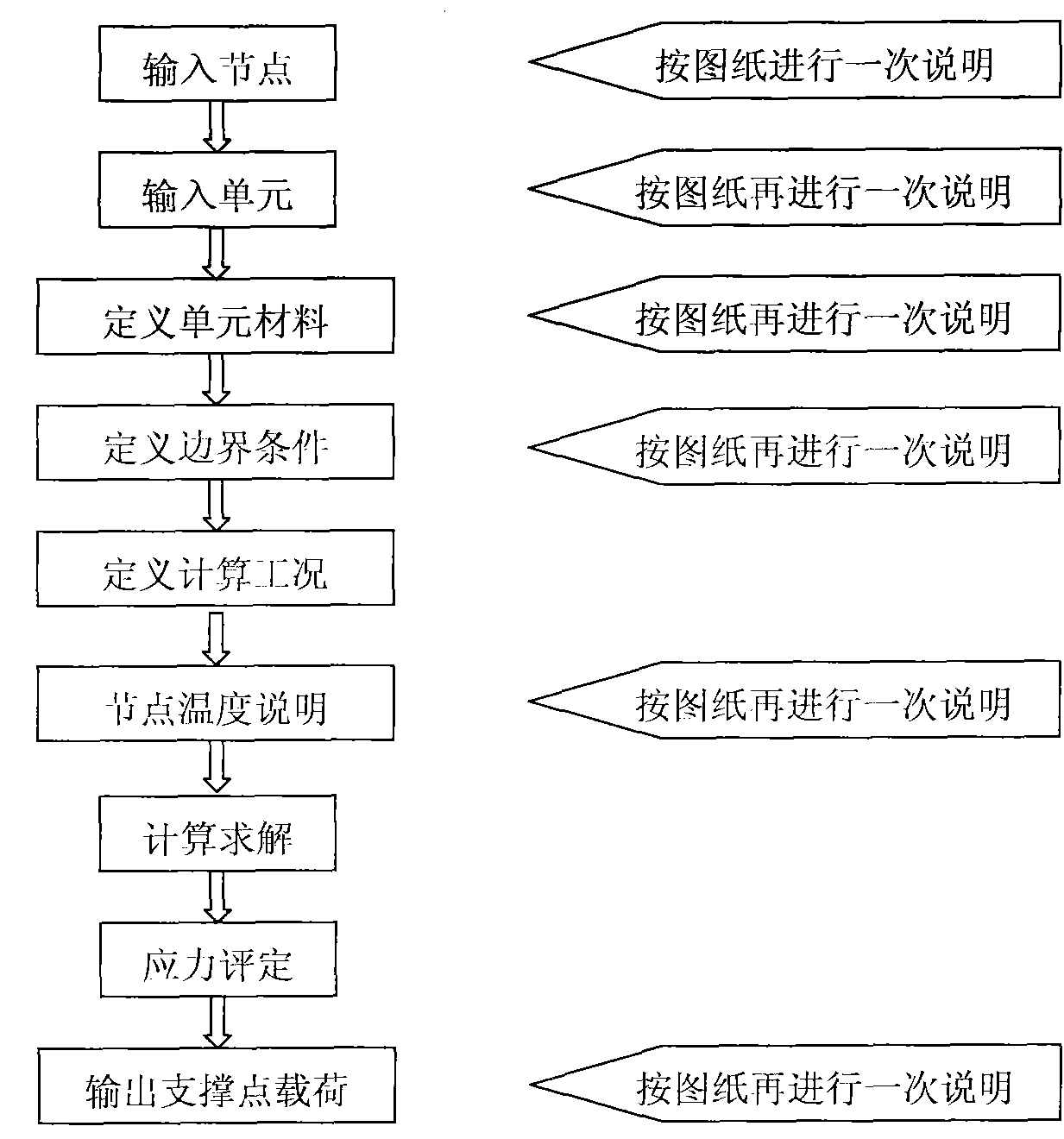

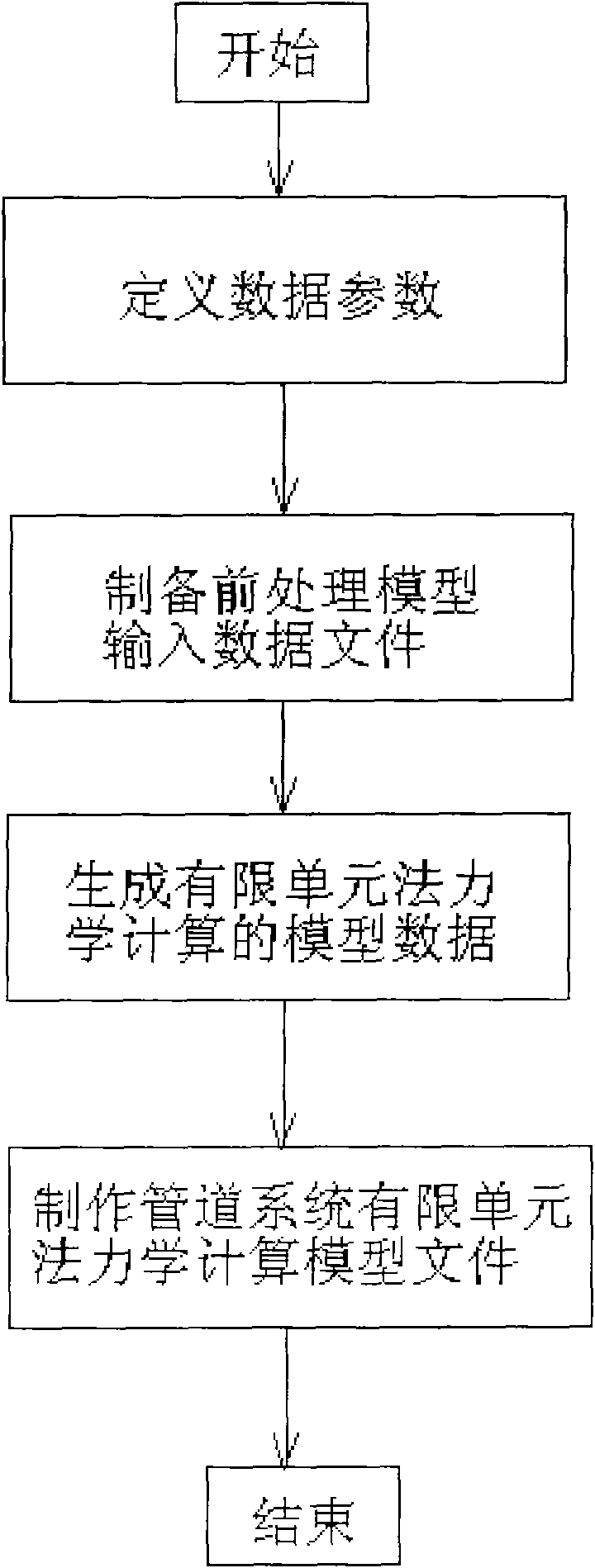

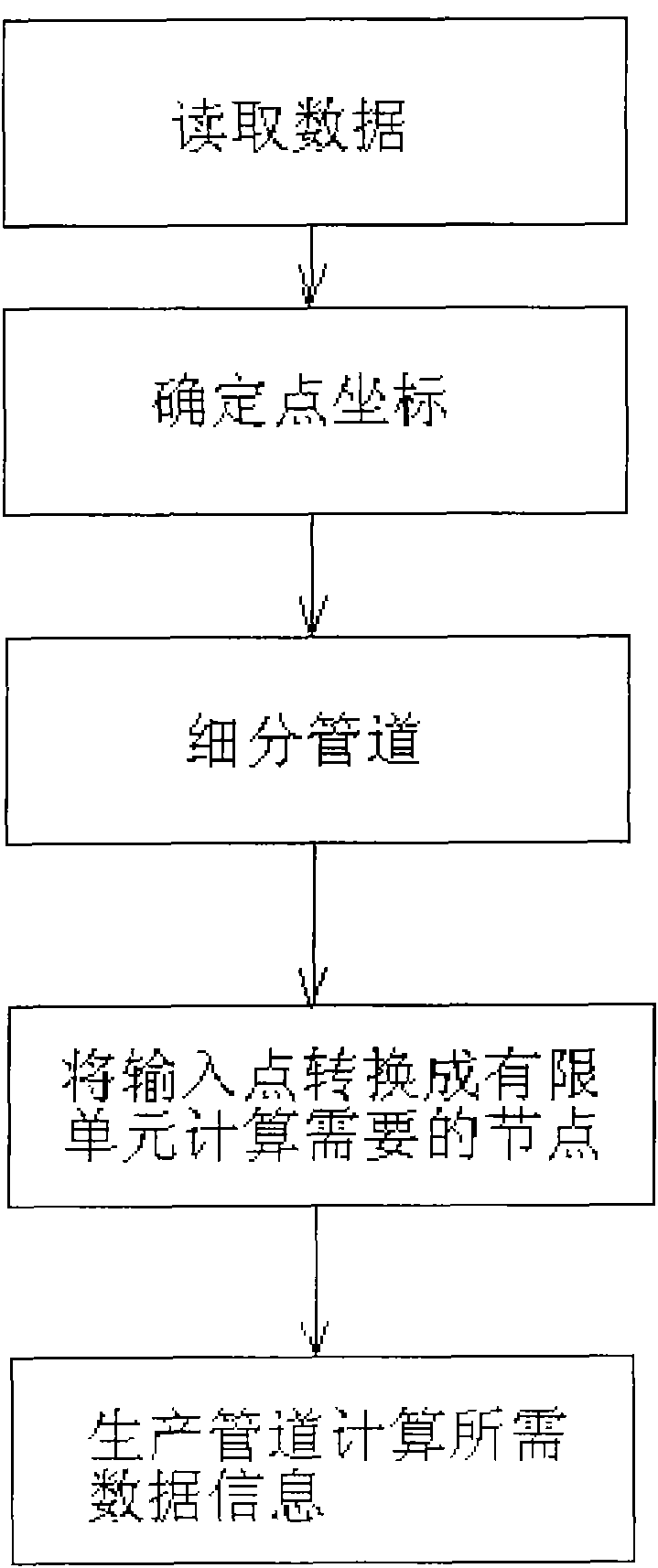

[0027] Such as figure 2 , image 3 As shown, a method for making a mechanical calculation model of a pipeline system with finite element method includes the following steps:

[0028] (1) Define the data parameter format, including coordinate parameters, elbow parameters, and coordinate offset parameters;

[0029] (2) Preparation of pre-processing model input data files: According to the design drawings of pipeline topics, make pre-processing model input data files, the data includes control data and model description data, the control data is effective for the entire calculation topic, and the model description data is used for illustration Enter point coordinates, pipe sections, dimensions, support points, and other properties. The data file is firstly the control data, followed by a one-time description of the pipeline geometry and physics as well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com