Large-scale central hydraulically-driven hydraulic automatic rake-lifting thickener

A concentrator and hydraulic technology, which is applied in the direction of separating sediments by centrifugal force, settling tanks, chemical instruments and methods, etc., can solve the problems of complex structure of the transmission device, limitation of the diameter of the concentration pool, and heavy load-bearing bridges, etc., to improve the concentration efficiency, The effect of high degree of equipment automation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

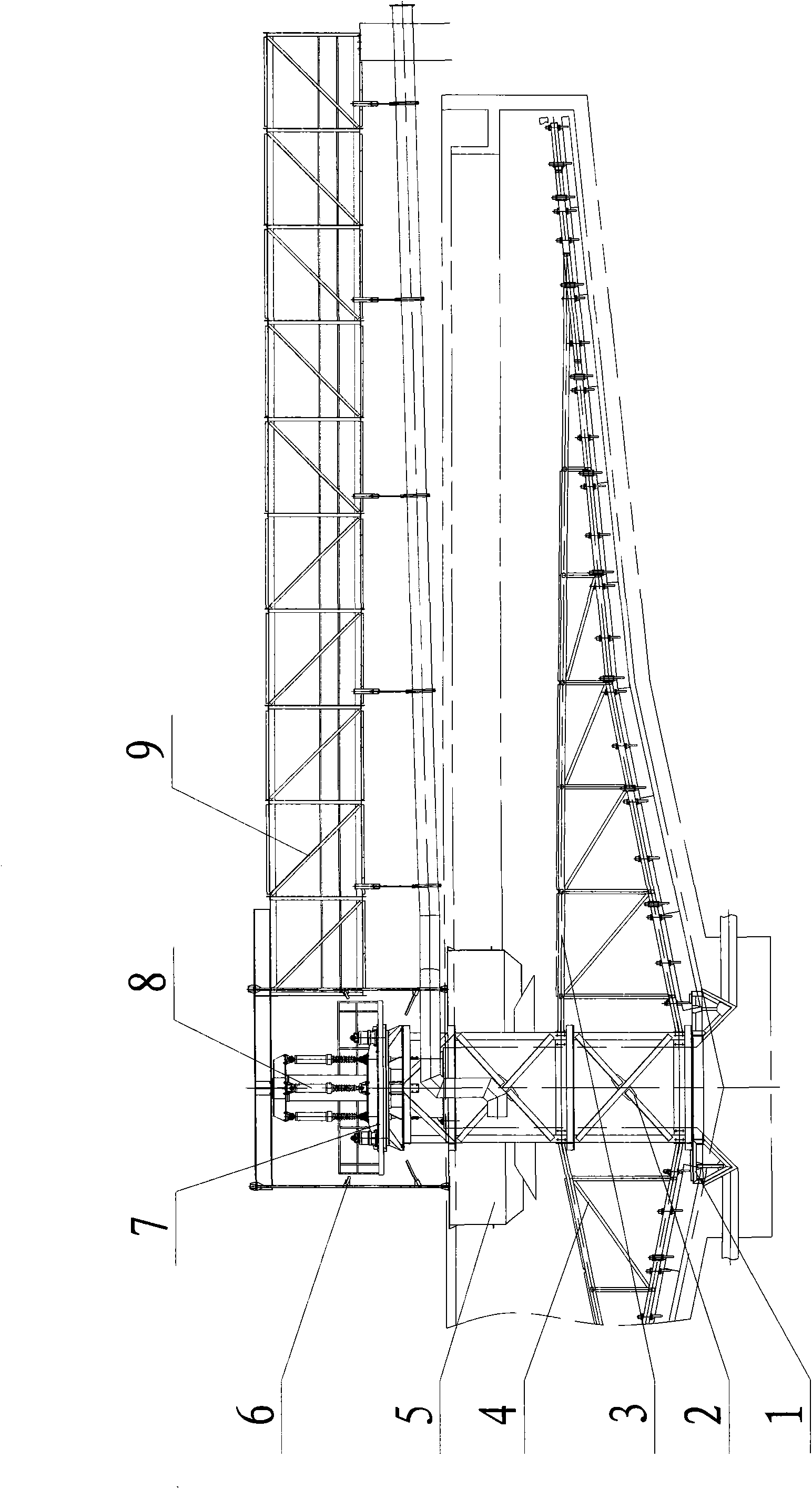

[0020] Such as figure 1 As shown, the present invention includes an auxiliary rake 1, a rotating cage 2, a long rake 3, a short rake 4, a distributing device 5, a hanging device 6, a transmission device 7, a rake lifting device 8, a bridge frame 9, and the like. The rotating cage 2 is connected with the long rake 3, the short rake 4 and the auxiliary rake 1, and the upper part of the transmission device 7 is connected with the rake lifting device 8 and the hanging device 6. The hydraulic system and the electric control system are installed on the platform of the hanging device 6, and automatically The distributing device 5 with dilution function is installed below the hanging device 6 , and the bridge frame 9 is fixed between the side wall of the concentration tank and the beam support 15 of the transmission device 7 .

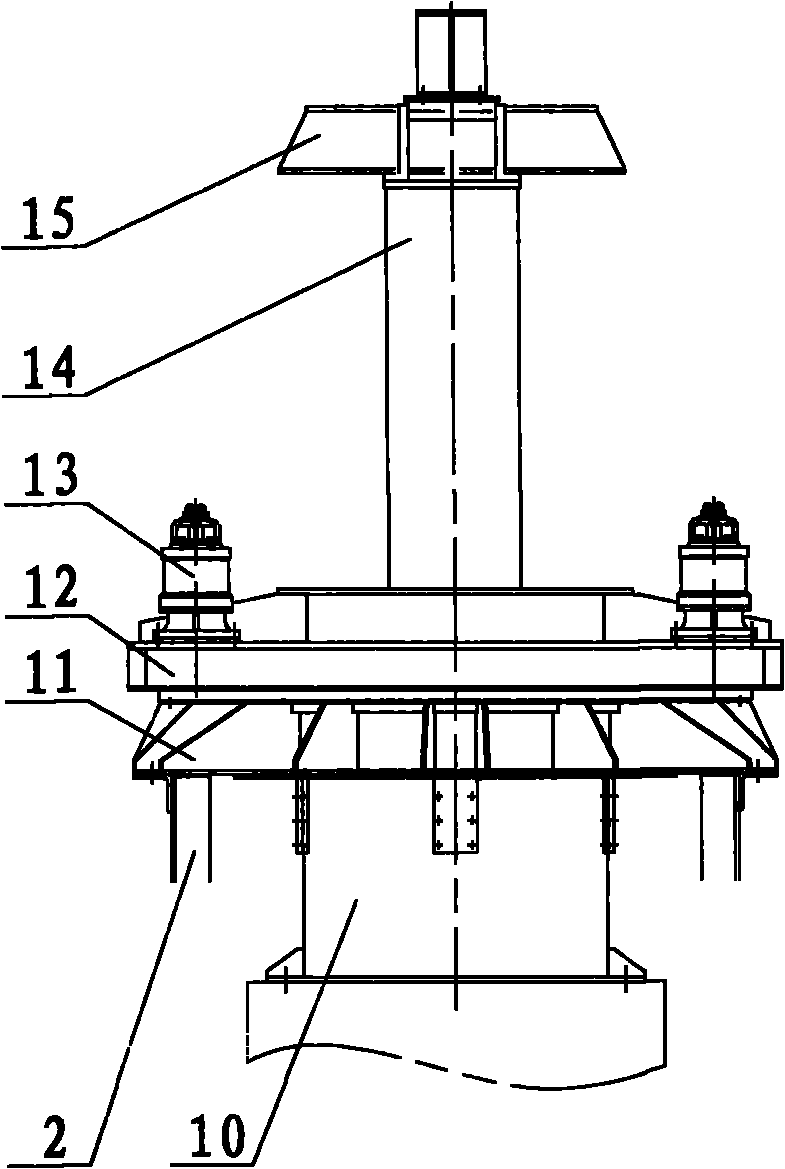

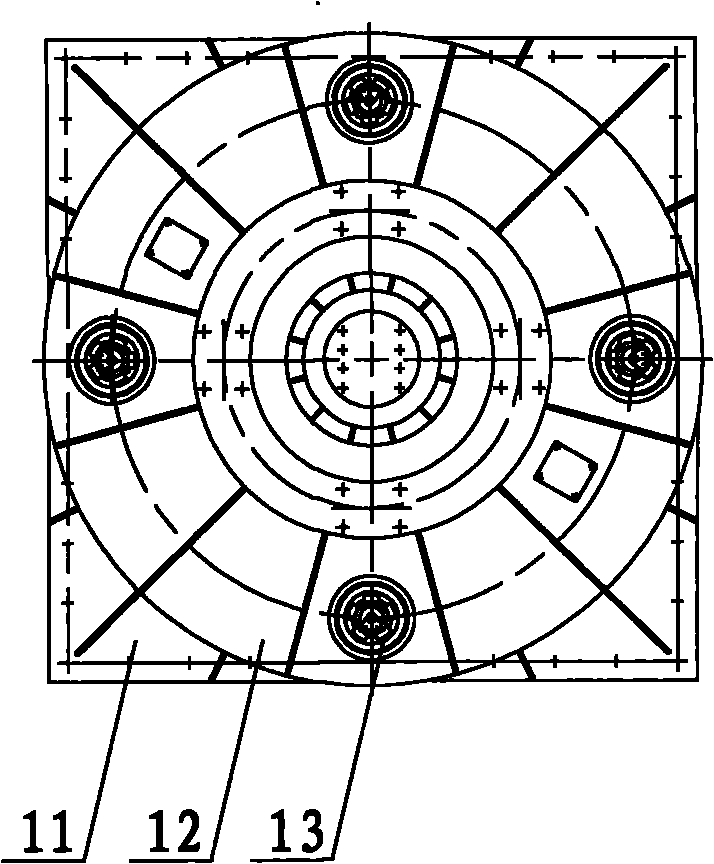

[0021] Such as Figure 2~3 As shown, the transmission device 7 includes a fixed support 10, a rotating support 11, an upper box 12, four hydraulic motor redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com