Continuous oil pipe steel strip butting technique

A steel strip and process technology, applied in the field of coiled tubing steel strip butt joint process, can solve the problems of wide welding heat affected area, many welding passes, unsuitable production, etc. The effect of weld structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

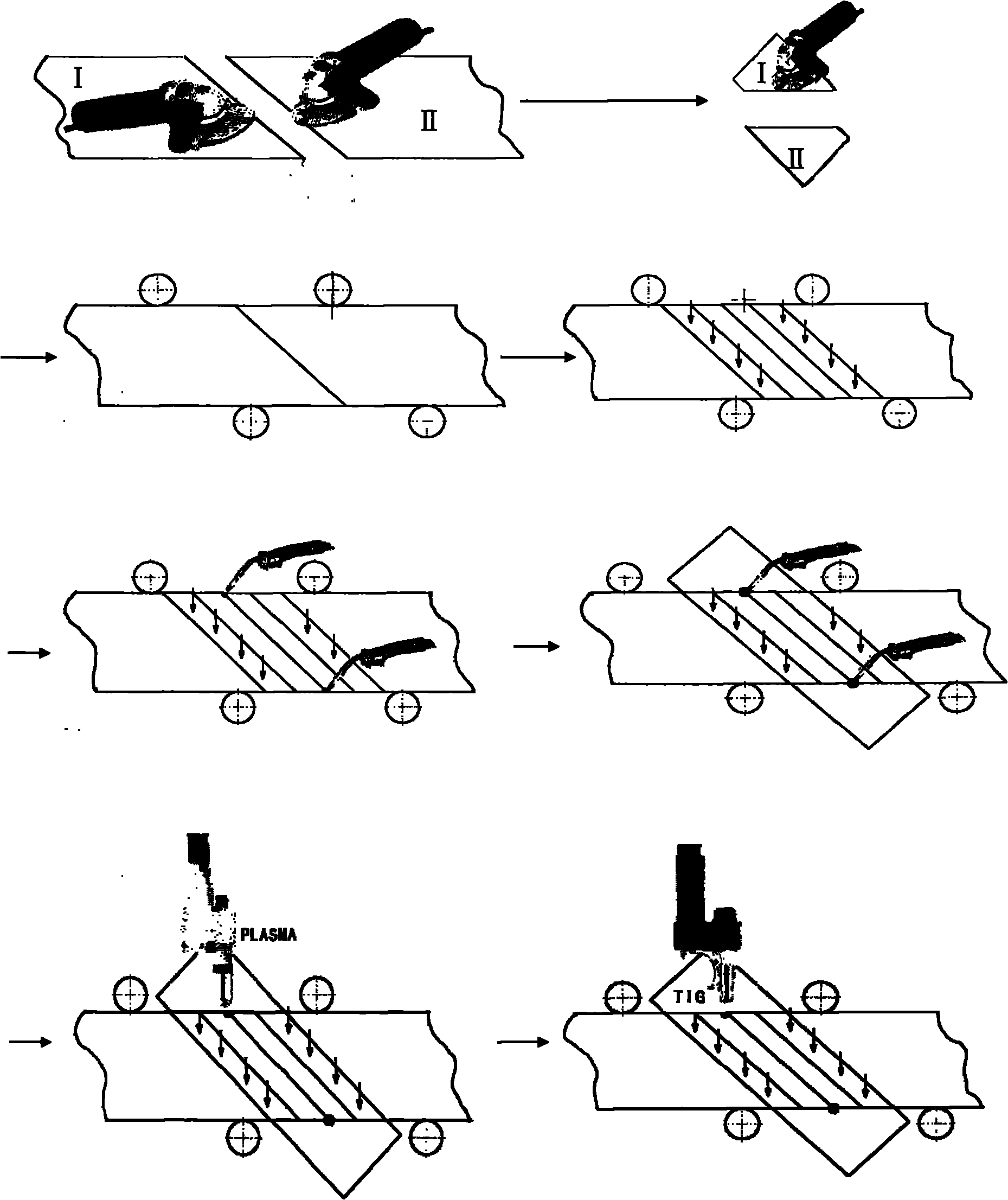

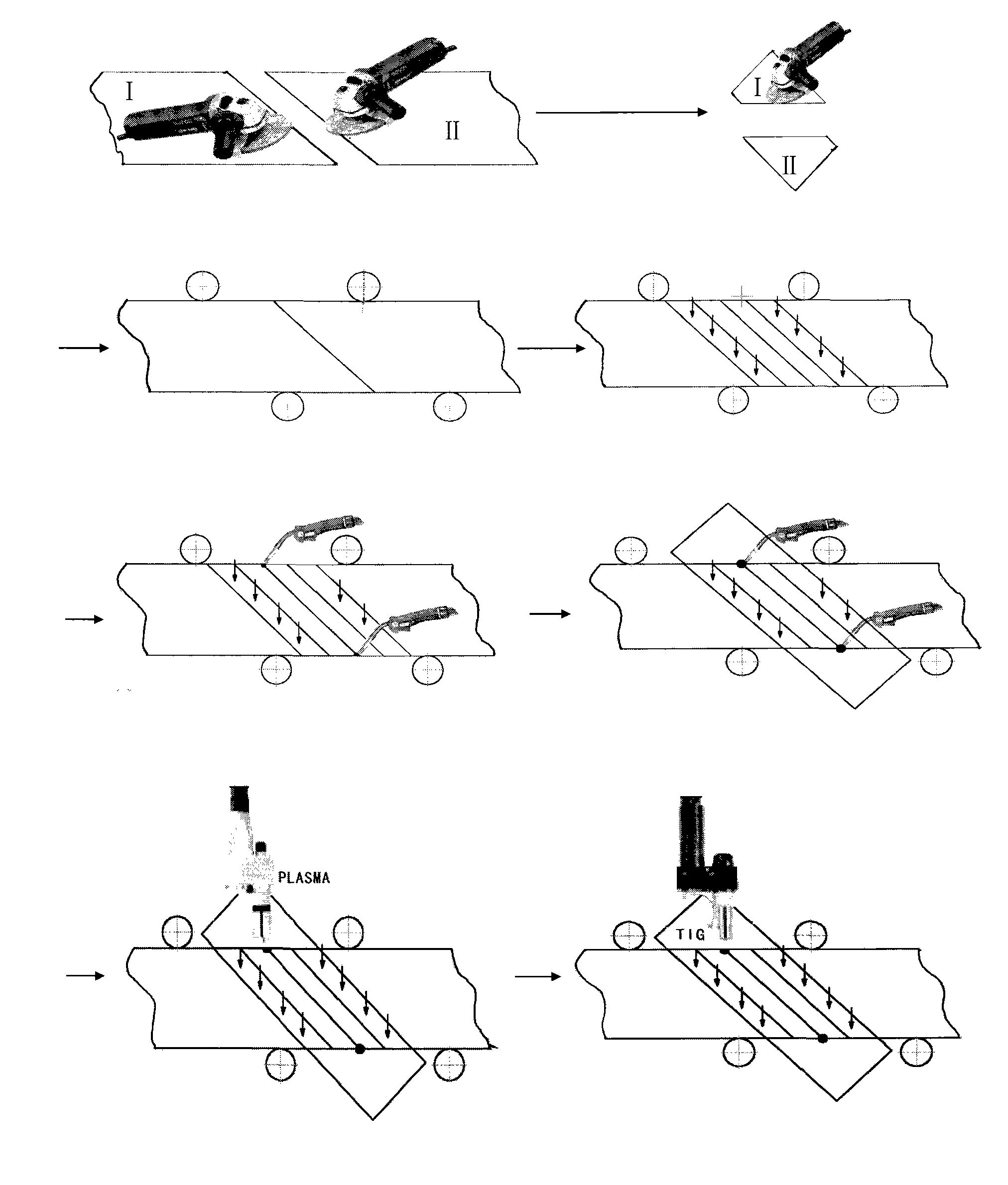

[0026] combined with figure 1 An embodiment of the present invention (steel strip size 3.18×120.2 mm) will be described.

[0027] 1. Cut the butt ends of steel strip I and steel strip II into 45° end faces, then polish and remove rust;

[0028] 2. Grind and derust the tangent end faces of the arc-extinguishing plate I, the arc-extinguishing plate II and the steel strip I and steel strip II;

[0029] 3. Align and compress the butt ends of steel strip I and steel strip II, and use manual TIG welding to spot weld and fix the butt ends of steel strip I and steel strip II to form a butt joint;

[0030] 4. Place the arc-extinguishing plate I and the arc-extinguishing plate II respectively at the head and tail of the opposite seam formed by the spot welding of the steel strip I and the steel strip II, and remove the arc-extinguishing plate I and the arc-extinguishing plate II by grinding The rusty end faces are closely attached to both sides of the steel strip I and steel strip II,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com