Grain dicing cover device with slide rail

A slide rail installation and pelletizing technology, which is applied in the field of pelletizing cover structure, can solve the problems of time-consuming and laborious, reduce production efficiency, complicated operation, etc., and achieve the effect of convenient use, high production efficiency, and easy air-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

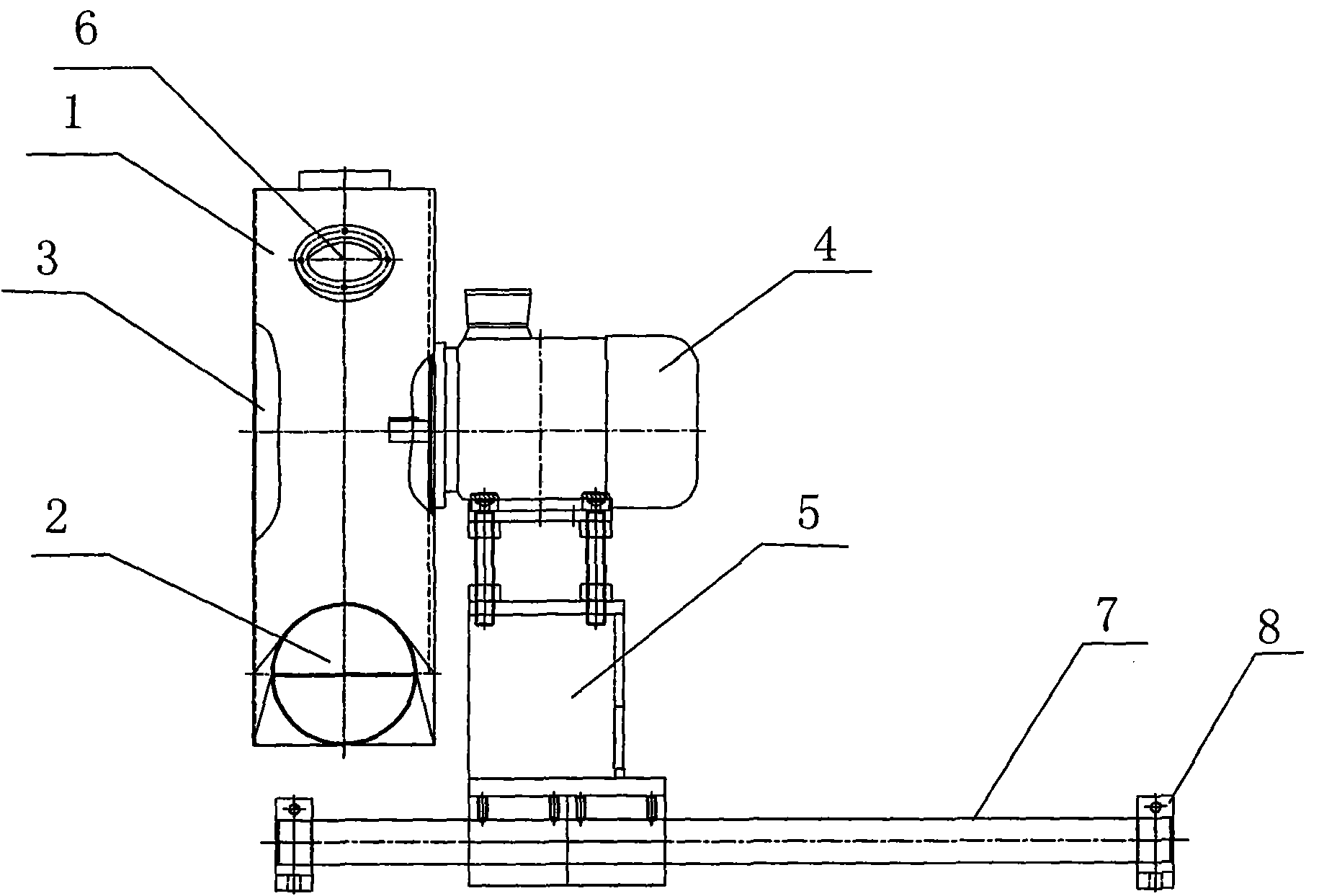

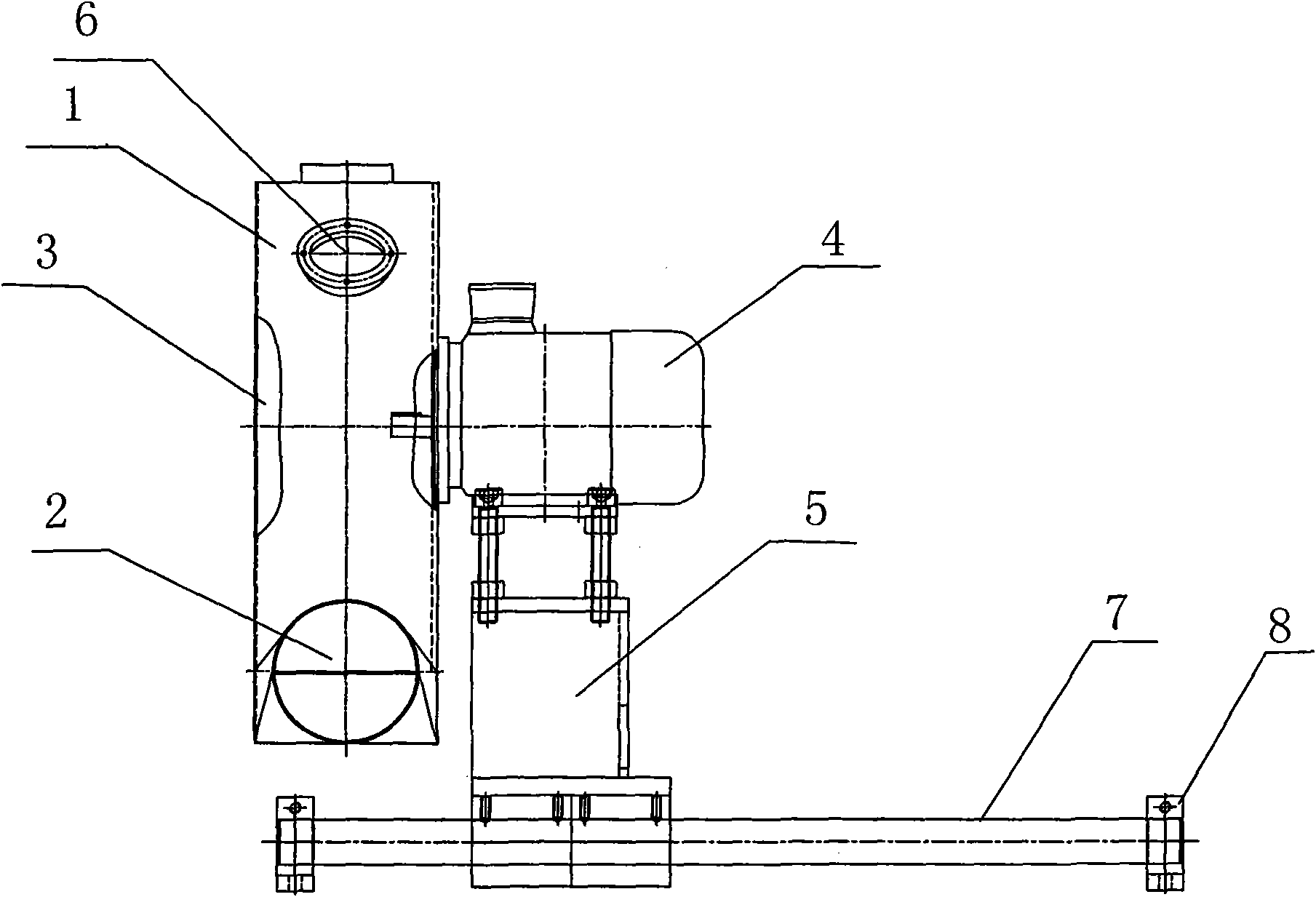

[0015] see figure 1 , the present embodiment is a kind of pelletizing cover device with slide rail, and it comprises the cover body 1 of a circular structure; What this cover body 1 adopts is that stainless steel material is welded to form, and in the manufacturing process, the plate selected should be Flat, without distortion, and the weld bead should be flat without obvious steps, making it beautiful and durable. An air inlet pipe and an air outlet channel 2 are relatively welded on the bottom of the cover body 10, and a blower fan can be arranged at the mouth of the air inlet pipe to air-dry and blow the granulated material.

[0016] It is worth noting that there is a circular hole 3 at the center of one side of the cover body 1. This circular hole 3 is compatible with the pelletizer head of the granulator, and the pelletizer head can be passed through the circular hole. 3 is placed in the cover body 1, and the cut granular material can be sent to the air outlet channel 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com