Production method of trehalose

A technology of trehalose and Pseudomonas putida, applied in the fields of fermentation engineering and microorganisms, can solve the problems of restricting the wide application of trehalose, high cost and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

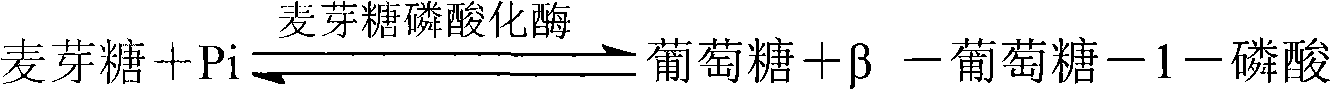

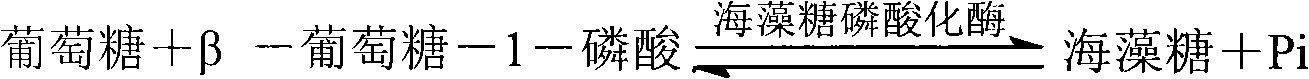

Method used

Image

Examples

Embodiment 1

[0043]Pseudomonas putida was collected and fermented on a shaking table at 30°C and 180r / min for 72h. The fermentation medium is: maltose 2wt%, peptone 0.5wt%, beef extract 0.2wt%, K 2 HPO 4 0.1wt%, NaH 2 PO 4 0.1wt%, MgSO 4 0.05wt%, balance water. After fermentation and cultivation, centrifuge at 4800r / min for 20min to obtain 100mL of concentrated bacterial liquid, which contains 10g of bacterial cells. Add 0.5mL of β-mercaptoethanol to the above-mentioned concentrated bacterial solution, and react for 2h to obtain a permeable cell solution of Pseudomonas putida. After 12 hours of centrifugation, the supernatant was taken to obtain a trehalose solution containing 4 g of trehalose.

Embodiment 2

[0045] Pseudomonas putida was collected and fermented on a shaking table at 30°C and 180r / min for 72h. The fermentation medium is: maltose 2wt%, peptone 0.5wt%, beef extract 0.2wt%, K 2 HPO 4 0.1wt%, NaH 2 PO 4 0.1wt%, MgSO 4 0.05wt%, balance water. After fermentation and cultivation, centrifuge at 10000r / min for 5min to obtain 50mL of concentrated bacterial liquid, which contains 5g of bacterial cells. Add 0.5mL of β-mercaptoethanol to the above-mentioned concentrated bacterial solution, and react for 2h to obtain a permeable cell solution of Pseudomonas putida, then add 5g of maltose to the obtained permeable cell solution of Pseudomonas putida, and react After 12 hours of centrifugation, the supernatant was taken to obtain a trehalose solution containing 2 g of trehalose.

Embodiment 3

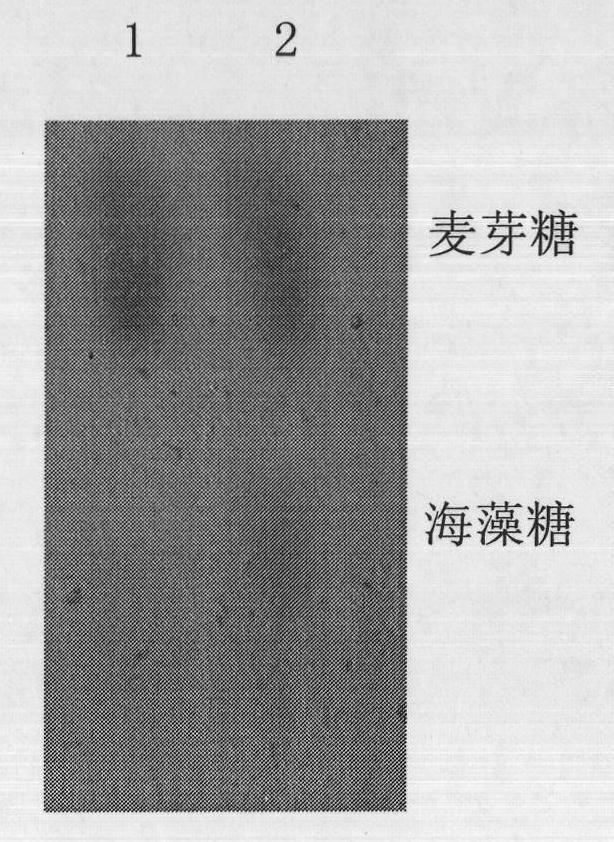

[0047] Pseudomonas putida was collected and fermented on a shaking table at 30°C and 180r / min for 72h. The fermentation medium is: maltose 2wt%, peptone 0.5wt%, beef extract 0.2wt%, K 2 HPO 4 0.1wt%, NaH 2 PO 4 0.1wt%, MgSO 4 0.05wt%, balance water. After fermentation and cultivation, centrifuge at 8000r / min for 10min to obtain 1000mL of concentrated bacterial liquid, which contains 80g of bacterial cells. Add 8 mL of β-mercaptoethanol to the above-mentioned concentrated bacterial liquid, react for 2 hours, and prepare a permeable cell solution of Pseudomonas putida, then add 100 g of maltose to the prepared permeable cell solution of Pseudomonas putida, and react for 12 hours , after centrifugation, the supernatant was taken to obtain a trehalose solution containing 31g of trehalose. After thin-layer chromatography of the trehalose solution and the untreated Pseudomonas putida cell solution cultured under the same conditions, it was found that about 30% of the maltos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com