Detection method for static load of pile foundation

A detection method and pile foundation technology, which is applied in the field of construction and foundation foundation, can solve the problems of static load counterweight weight, inability to detect, high detection cost, etc., and achieve the effect of simple detection equipment, wide application range and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] The invention discloses a method for detecting the static load of a pile foundation, the steps of which are as follows:

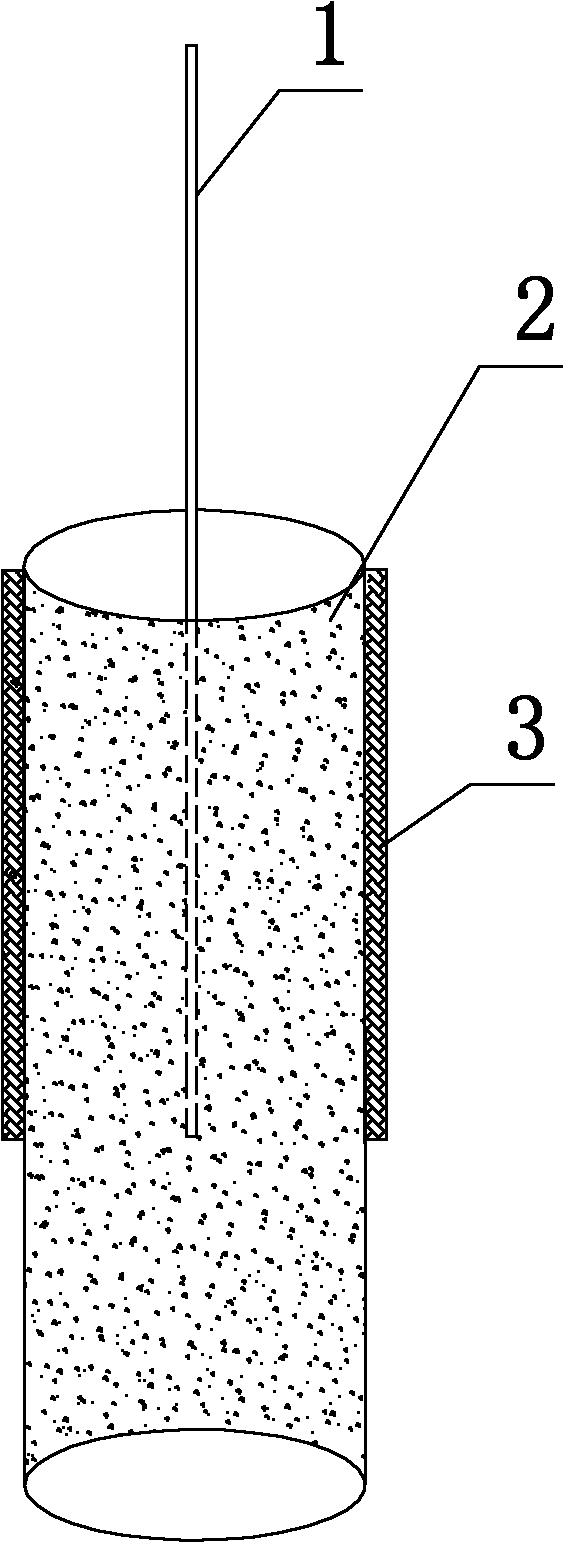

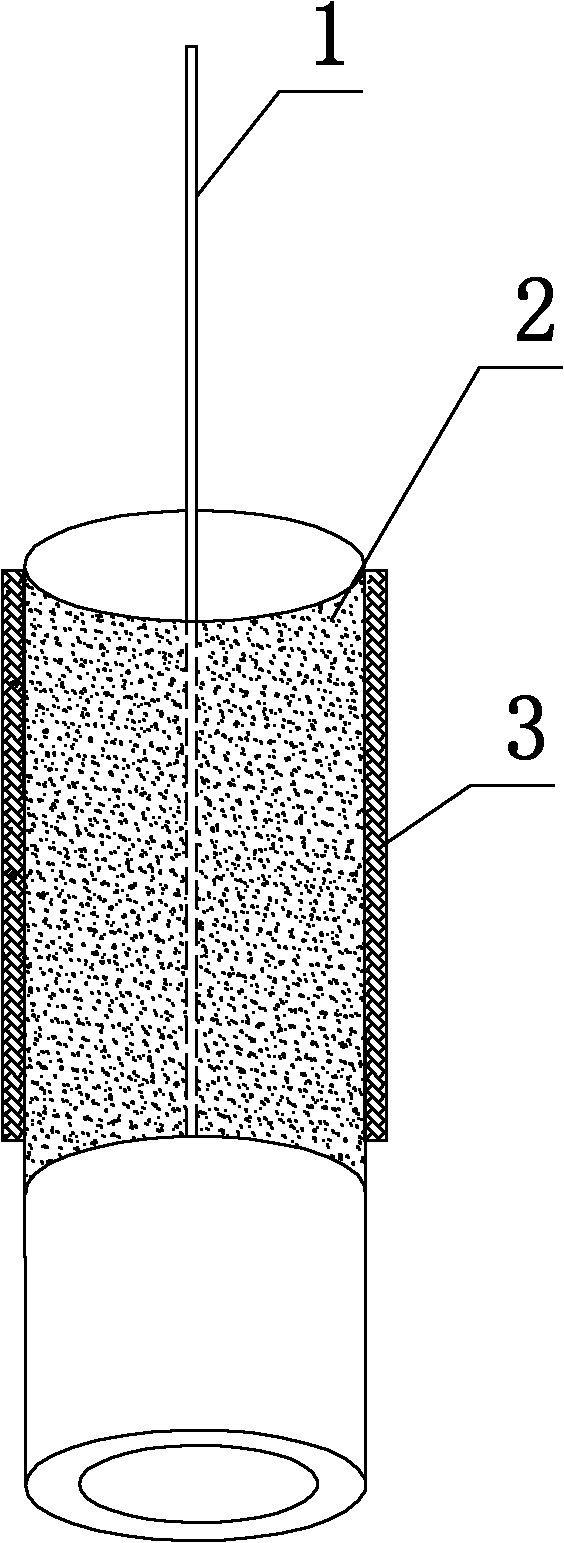

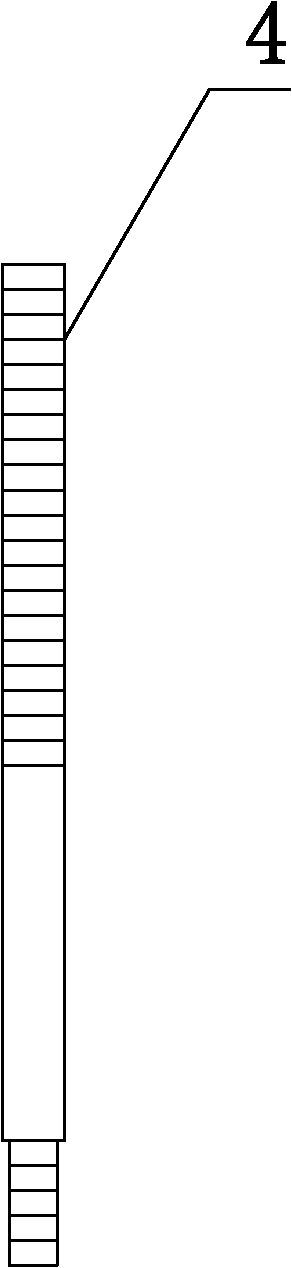

[0042] ①Installation: Pre-embed one or more anti-pull rods 1 on the top of the pile foundation 2 to be tested and connect it with the pile foundation 2 to be tested, paste a carbon fiber layer 3 on the outer wall of the pile foundation 2 to be tested, and the pile to be tested The height of the carbon fiber layer 3 pasted on the foundation 2 is greater than or equal to the length of the anti-pull rod 1 embedded in the pile foundation 2 to be detected. The invention utilizes the advantageous condition that the frictional resistance per unit area of the concrete and the anti-pull rod 1 is greatly increased under three-dimensional stress, and embeds the anti-pull rod 1 in the pile foundation 2 to be detected....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com